Miscanthus floridulus stalk gluing device and method

A five-section awn and stem technology, which is applied to adhesive application devices, wood processing equipment, manufacturing tools, etc., can solve the problems of undiscovered reports and real objects, inability to be recombed on the surface of gluing objects, uneven penetration of glue, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

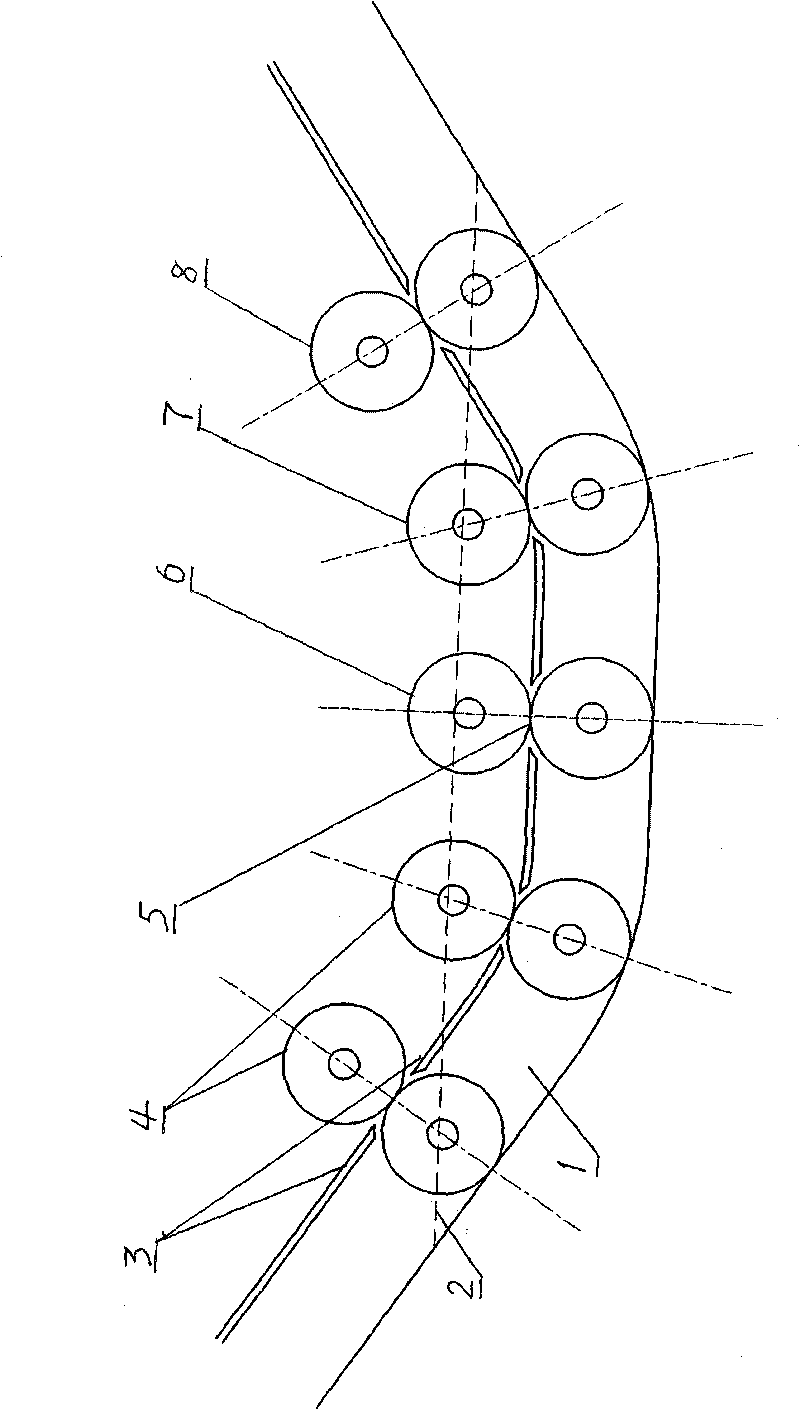

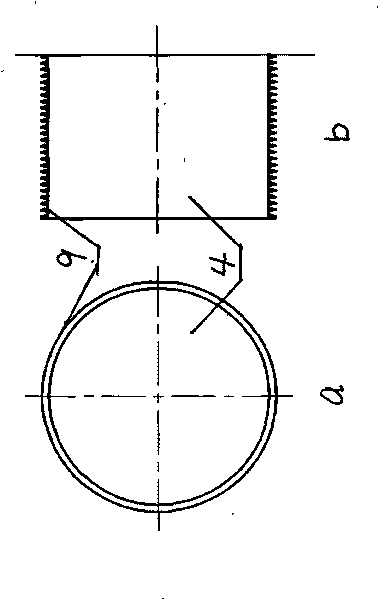

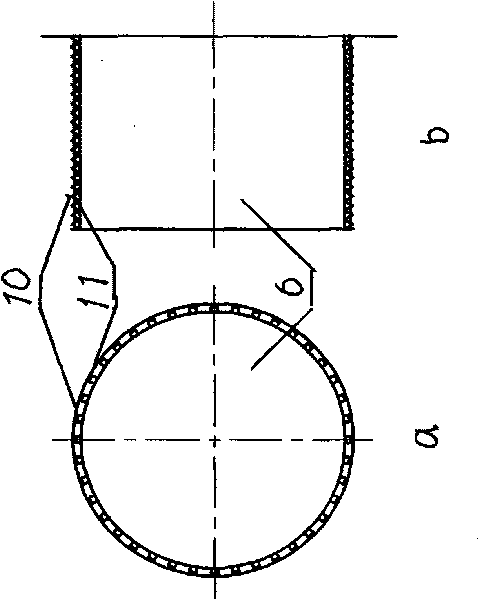

[0017] The present invention is described in further detail below in conjunction with embodiment and with reference to accompanying drawing: figure 1 , the five-section awn stalk sizing device includes a frame, a motor and its speed regulation and transmission mechanism, a glue pool 1 and upper and lower pressure rollers, and is characterized in that said upper and lower pressure rollers are at least five pairs, with the feeding direction The sequence is one to two pairs of slitting rollers 4, one pair of cutting and pressing rollers 6, 1-3 pairs of pressing rollers 7, one pair of extruding rubber rollers 8, and the diameter of each pair of upper and lower rollers is 80-400mm. There are elastic devices at both ends of the roller shaft, which are installed together on the frame outside the glue pool 1. There is a feeding gap 5 between the upper and lower rollers close to the roller surface. The front and rear sides of the feeding gap 5 have independent and discontinuous The mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com