Bionic non-smooth surface film with pneumatic drag reduction effect

A non-smooth surface, non-smooth technology, applied in the direction of body, body stability, transportation and packaging, etc., can solve the problem of small air resistance of the body, and achieve the effect of reducing the air resistance coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

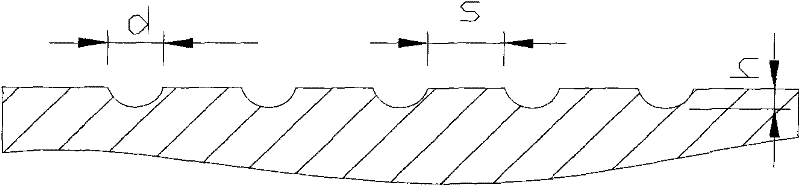

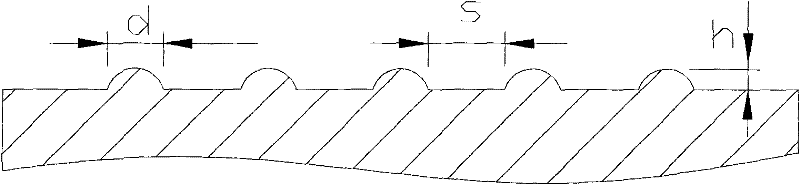

[0035] refer to Figure 7 , a non-smooth drag-reducing film mainly covering the roof of the vehicle body, the surface of the film is evenly distributed with pit-shaped non-smooth units u, the unit diameter d is 1.5mm, the unit depth h is 0.75mm, and the unit u The horizontal spacing s is 9.0mm, the vertical spacing l is 9.0mm, and it is pasted on an area of 1.2m 2 The drag coefficient of the car on the roof of the car body can be reduced by about 5.6%.

Embodiment 2

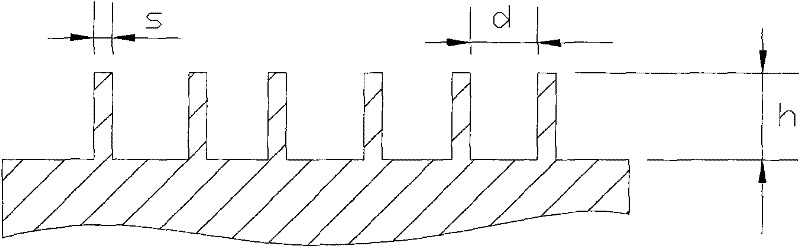

[0037] refer to Figure 8 , a non-smooth drag-reducing film mainly covering the roof of the vehicle body, the surface of the film is evenly distributed with groove-shaped non-smooth units u, the stripe width s is 1.0mm, the stripe height h is 1.0mm, and the stripe unit spacing d is 12mm, stick it on an area of 1.2m 2 The drag coefficient of the car on the roof of the car body can be reduced by about 8.20%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com