Adaptive biomimetic non-smooth surface film with aerodynamic drag reduction

A non-smooth surface, non-smooth technology, used in axle box lubrication, climate sustainability, transportation and packaging, etc., can solve the problems of reducing the aerodynamic drag coefficient, it is difficult to make breakthrough progress, etc., to reduce the body aerodynamic drag coefficient. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The purpose and effect of the present invention will become more obvious by referring to the accompanying drawings to describe the present invention in detail.

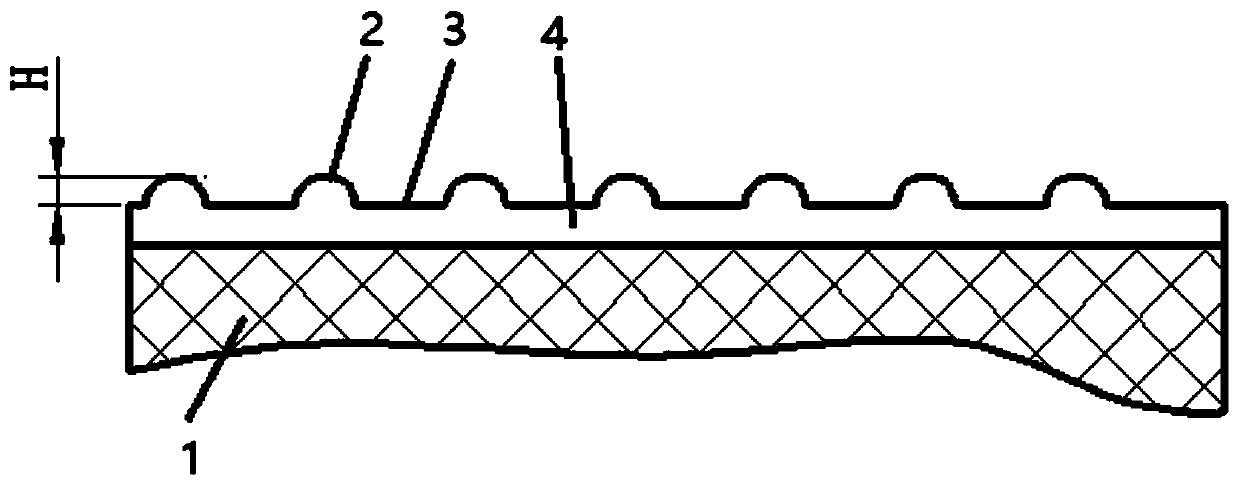

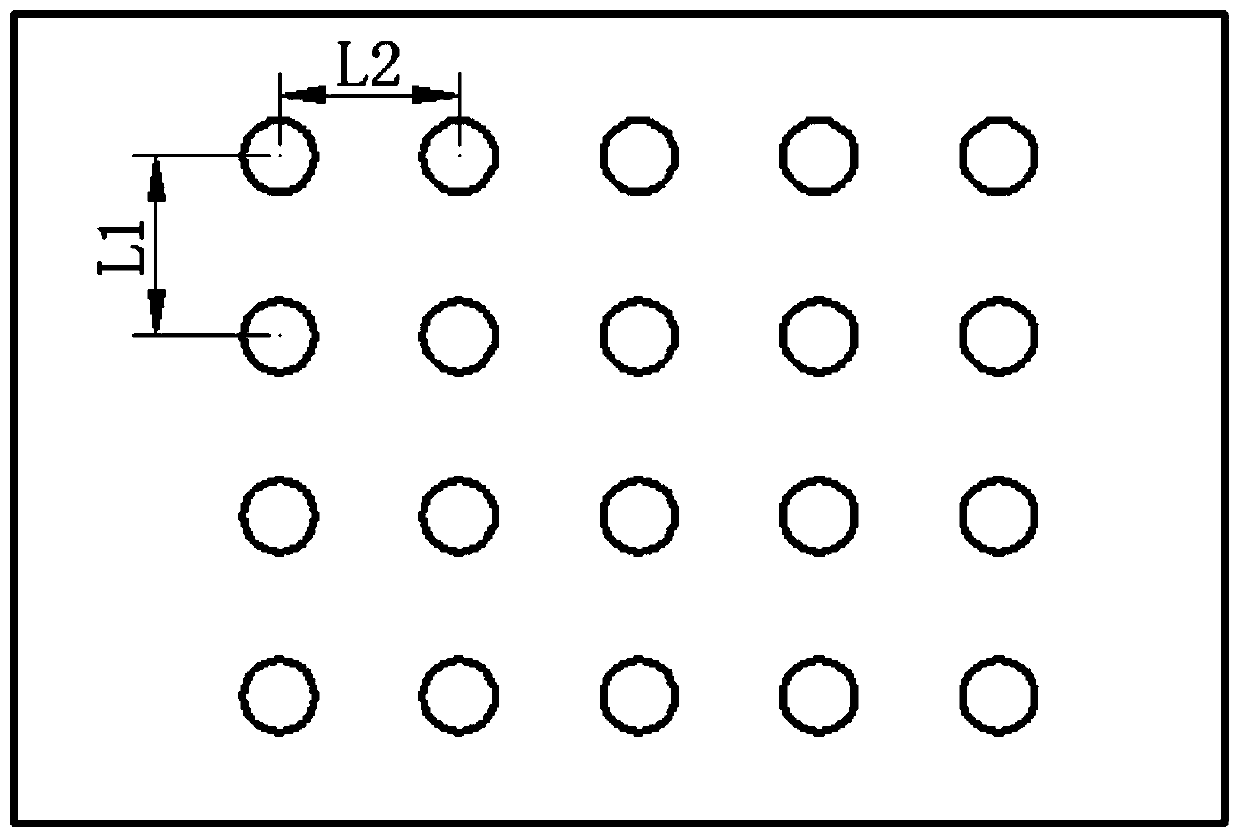

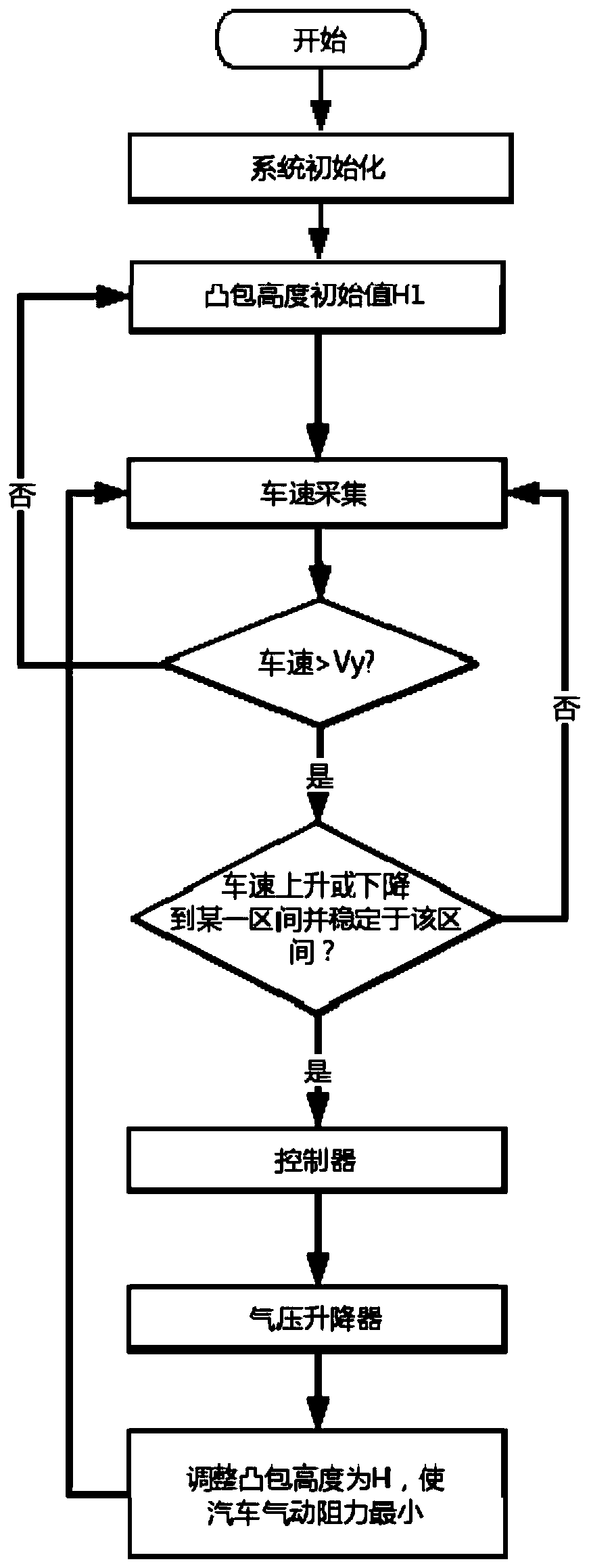

[0023] The self-adaptive bionic non-smooth surface film with aerodynamic drag reduction function of the present invention comprises a substrate, a variable-volume non-smooth unit, a non-smooth unit carrier, an air-filled cavity, an air pressure lifter in the cavity, a vehicle speed signal receiver, and a controller. structured as figure 1 As shown, variable height non-smooth unit 2 adopts non-metallic materials with less rigidity, especially materials with elastic modulus lower than 100MPa, such as rubber, PVC0.007 plasticized, non-smooth unit carrier 3 and matrix 1 are Non-metallic materials with higher rigidity, especially materials with elastic modulus higher than 1GPa, such as high-pressure polyethylene and polypropylene, and the non-smooth unit 2 are sealed and bonded to each opening of the non-smooth unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com