Multi-point side-discharging device of filling belt conveyer

A belt conveyor, multi-point technology, applied in the direction of conveyor objects, fillings, safety devices, etc., can solve the problems of many unloading points, unsuitable belt conveyors, and difficulty in backfilling materials in goafs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

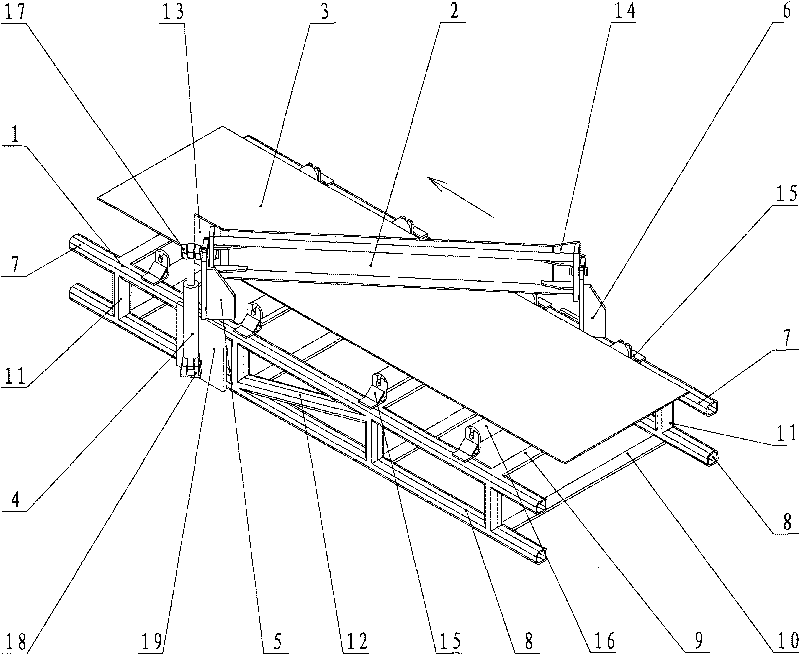

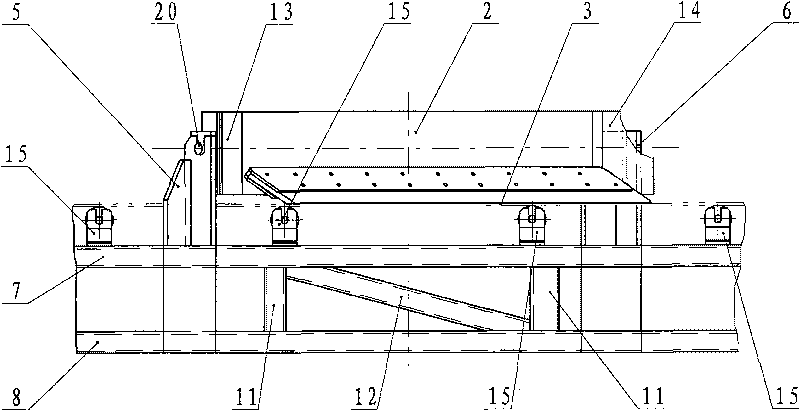

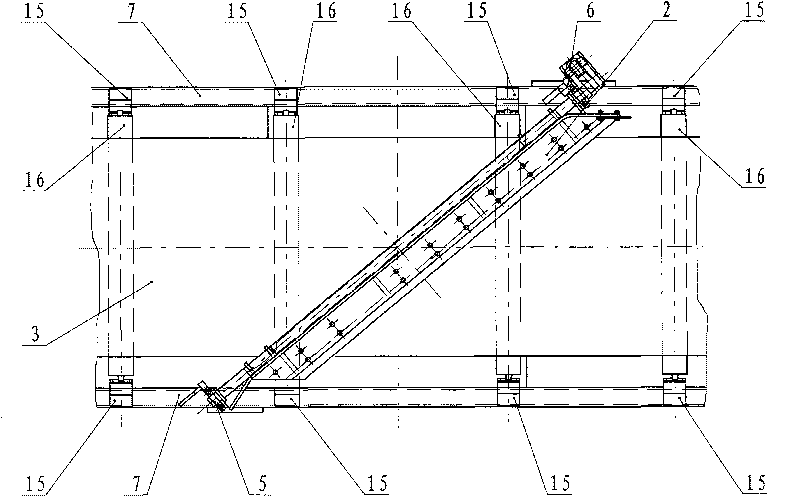

[0022] The present invention will be further described below in conjunction with accompanying drawing:

[0023] figure 1 , 2 , 3, and 4 show the structural diagram of the multi-point side unloading device for the belt conveyor for filling. The position and connection relationship of each part must be correct and the installation should be firm.

[0024] The middle frame is the main body of the belt conveyor, welded structure, good strength, and made of alloy structural steel.

[0025] Conveyor belts, idler frames, and idlers are the moving parts of the conveyor, which must rotate flexibly and run smoothly.

[0026] The oil cylinder seat, the oil cylinder turning seat, the oil cylinder base and the oil cylinder supporting plate should be installed firmly, and the adjustment should be reasonable, and they should be used together with the turning type soil dividing plate.

[0027] Figure 5 As shown, it is the structural diagram of the flip-type soil splitter. One end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com