Intelligent control preheating device

A preheating device, intelligent control technology, applied in the direction of temperature control, control/regulation system, non-electric variable control, etc., can solve the problems of printed circuit board deformation, difficult to control the preheating equipment preheating time, PCBA heating and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

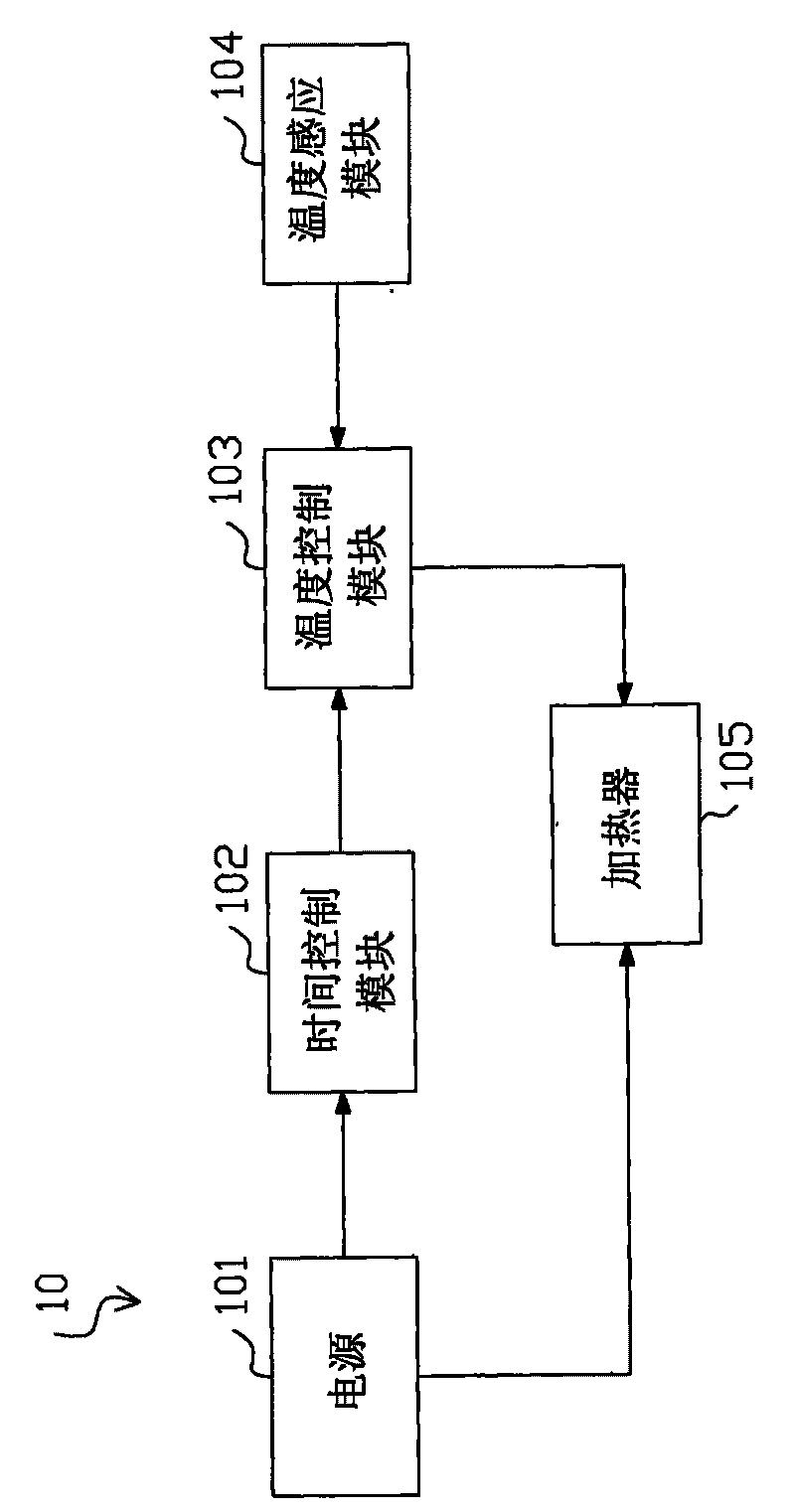

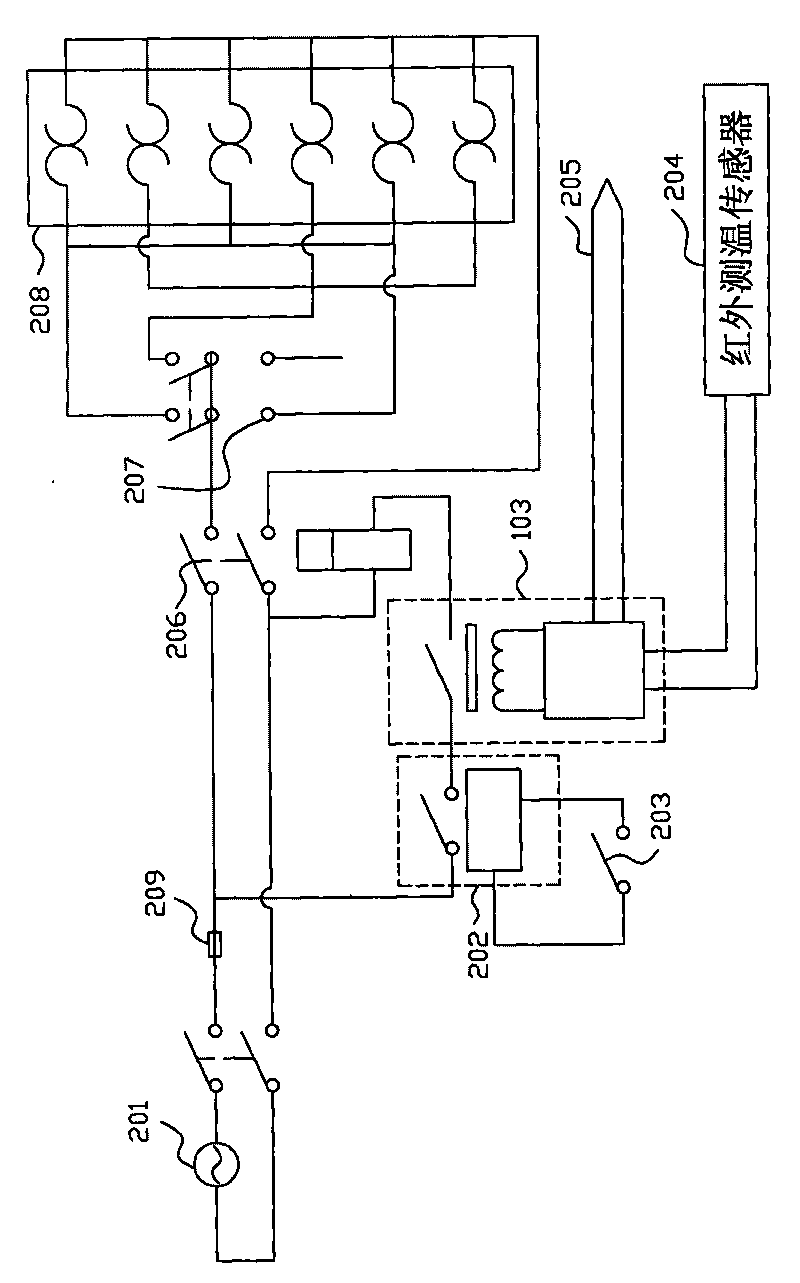

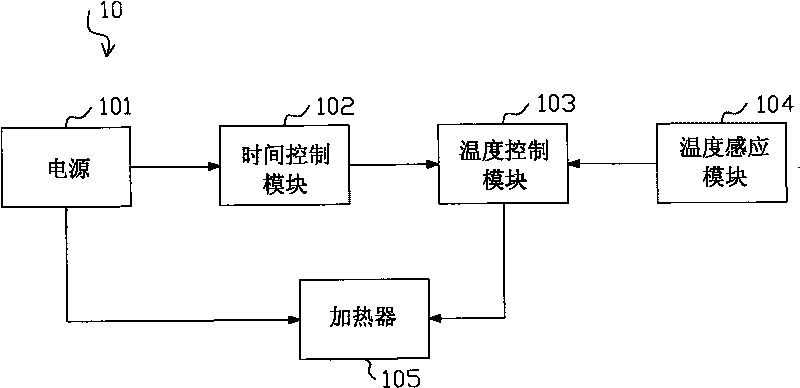

[0011] Please refer to figure 1 and figure 2 shown. The intelligent control preheating device 10 of the present invention is mainly suitable for the rework and preheating process of printed circuit board assembly (PCBA). By controlling the preheating temperature and preheating time, the PCBA rework scrap rate can be effectively reduced.

[0012] The intelligent control preheating device 10 of the present invention mainly includes a power supply 101 , a time control module 102 , a temperature control module 103 , a temperature sensing module 104 and a heater 105 .

[0013] Wherein, the temperature sensing module 104 is used to detect the temperature on the surface of the printed circuit board (not shown) placed on the preheating operation panel, and transmit the temperature signal to the temperature control module 103; the temperature control module 103, one end of which is electrically connected to the temperature sensing module 104 to receive the temperature signal transmi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap