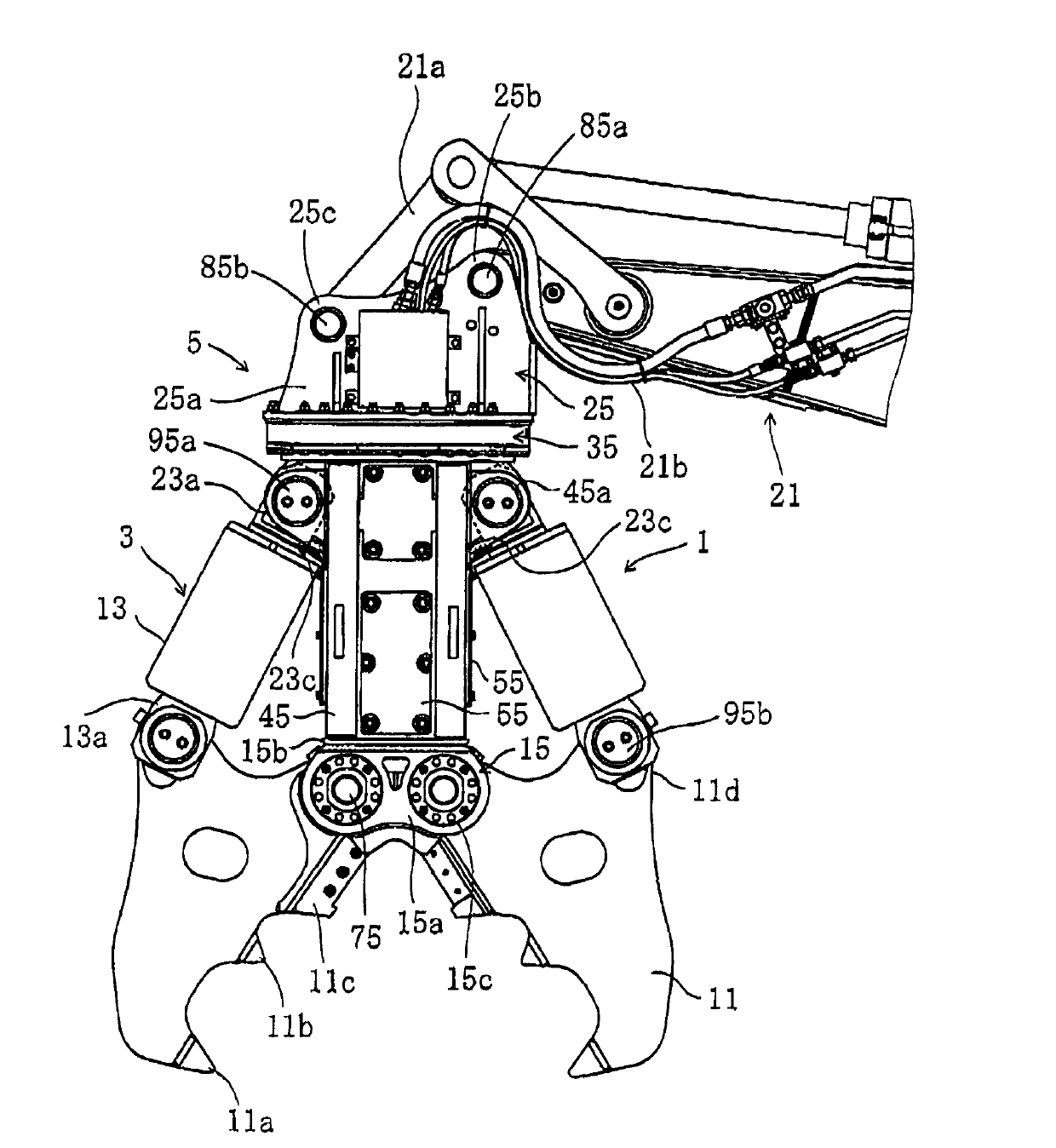

Hydraulic crusher

A hydraulic crushing and crushing machine technology, which is applied in earth moving machines/excavators, building maintenance, construction, etc., can solve the problem of easy damage, broken shells clamped in the main body of the cylinder 113 and the second hydraulic software connected to the piston rod. Between the pipes 109, 119, ..., the second hydraulic hose damage and other problems, to achieve the effect of suppressing irregular movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

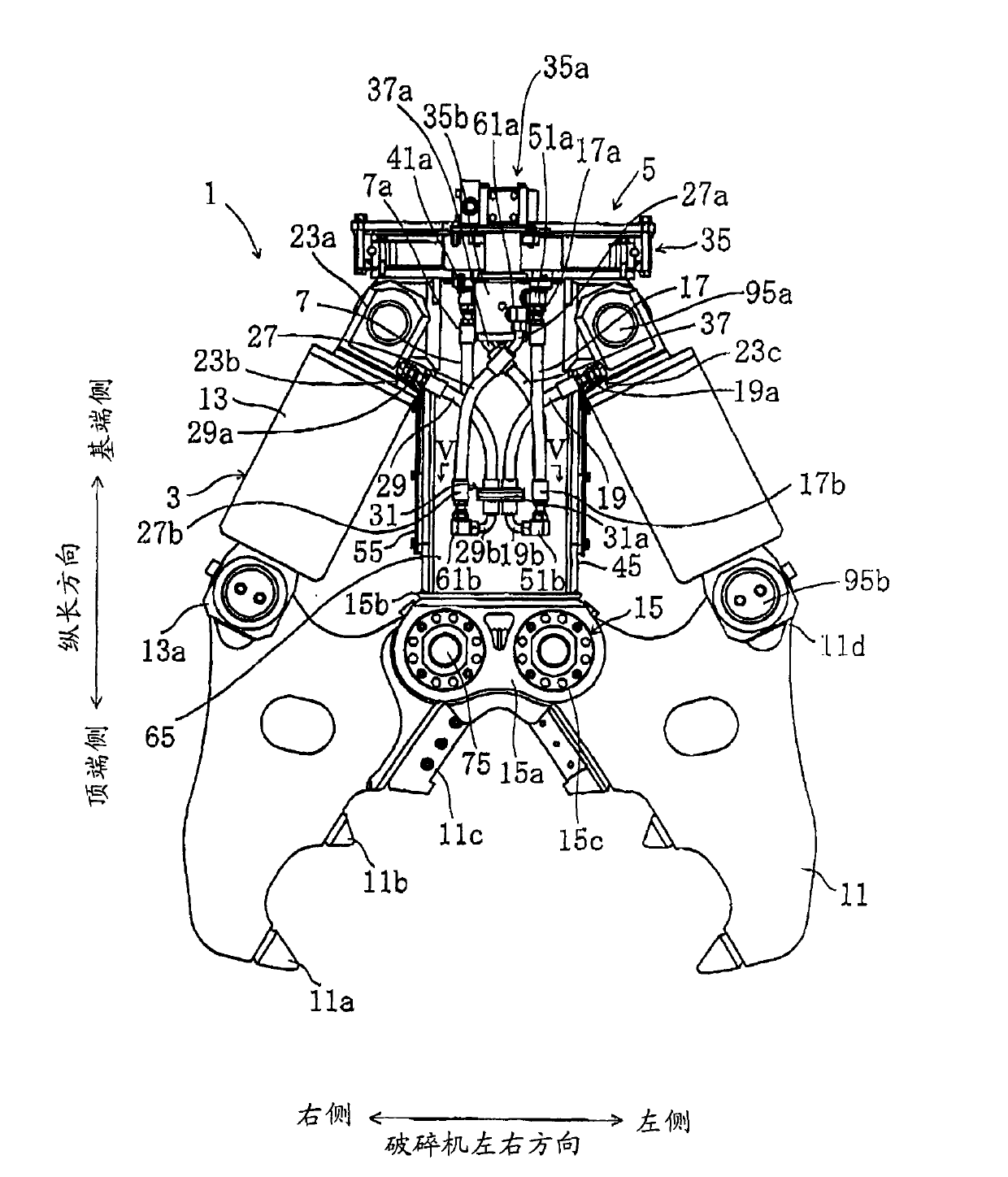

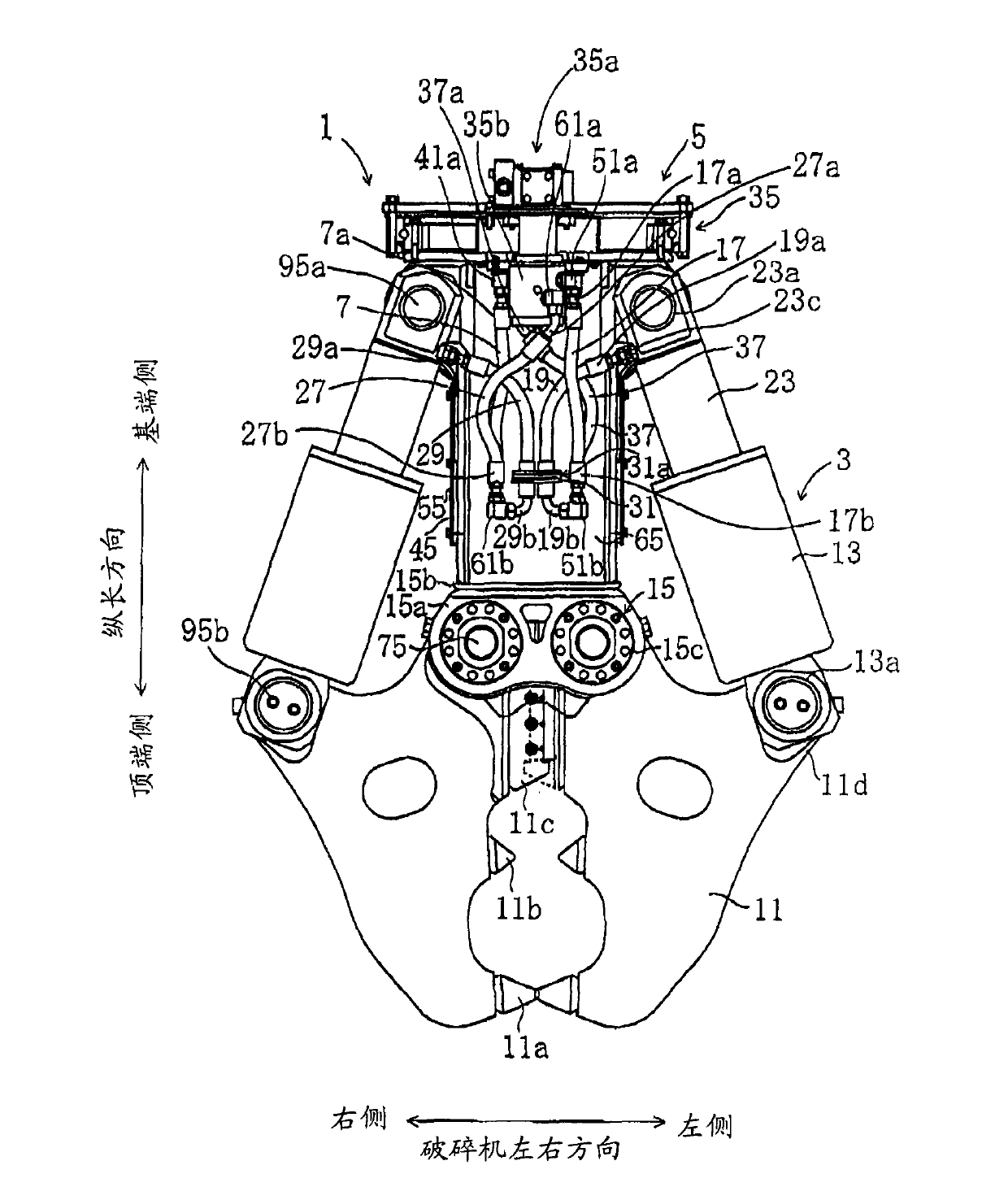

Method used

Image

Examples

other Embodiment approach

[0097] The present invention is not limited to the embodiments, and can be implemented in various other forms without departing from the spirit or main characteristics.

[0098] In the above-mentioned embodiment, the relay mechanism is constituted by the distal end side joints 9b, 19b, . . . It may be configured such that the front-end side joints 7b, 9b, .

[0099] In addition, in the above-mentioned embodiment, the second hydraulic hoses 9, 19, ... are bundled at the central part of the cavity part 65 when viewed from the longitudinal direction, but only the top ends of the four second hydraulic hoses 9, 19, ... part and the top ends of the four first hydraulic hoses are separated by a predetermined distance, then the second hydraulic hoses 9, 19 can also be bundled in such a way as to surround the first hydraulic hoses 7, 17, ... with an annular clamp ,….

[0100] In addition, in the above-described embodiment, the distal end side joints 9b, 19b, ... of the respective sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com