An automatic adjustment device for spray boom balance

An automatic adjustment and spray boom technology, which is applied to the device for catching or killing insects, application, animal husbandry, etc., can solve the problem of reducing the uniformity of spraying, the uniformity of spraying can not be guaranteed, and the lack of effective control of the horizontal movement of the spray boom and other problems to achieve the effect of reducing horizontal movement and improving operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

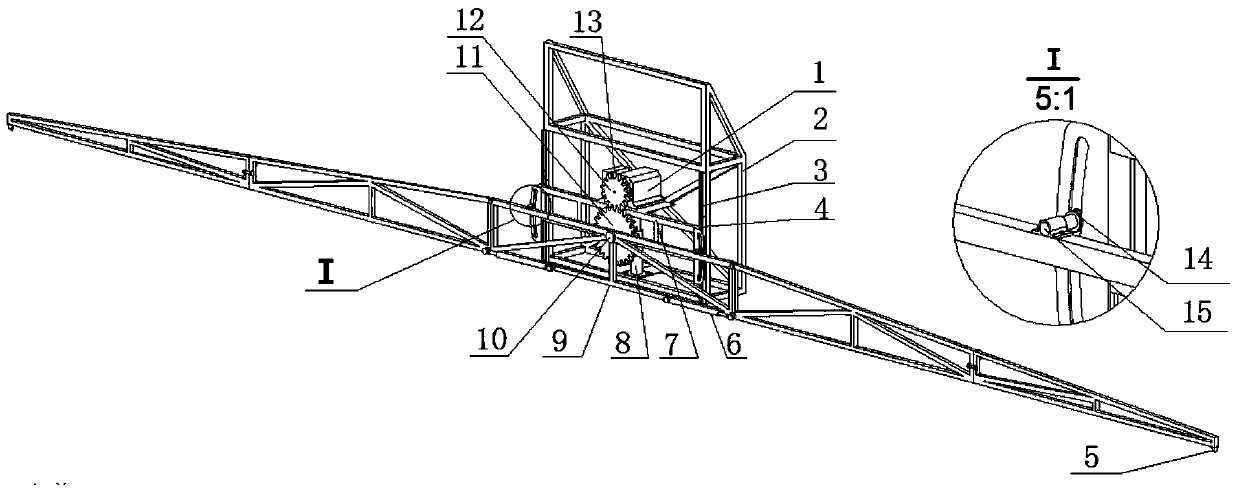

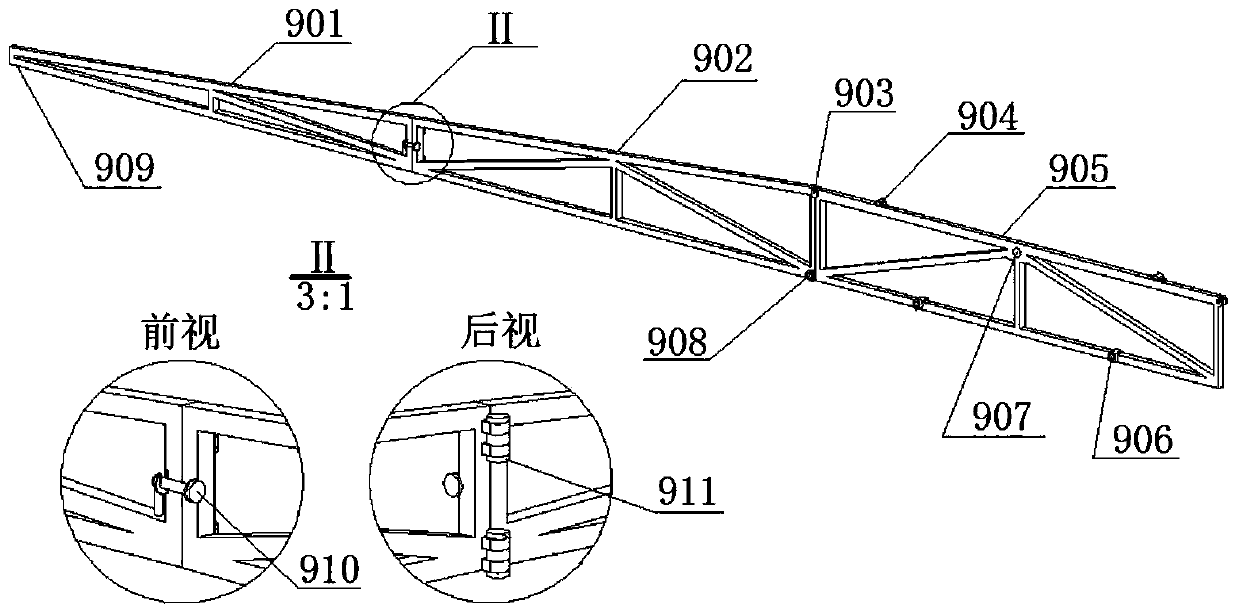

[0029] like figure 1 As shown, the spray boom balance automatic adjustment device of the present invention includes a DC stepping motor 1, a fixed frame 2, a slide rail 3, a slider 4, a folding hydraulic cylinder 6, a height adjustment frame 7, and a height adjustment hydraulic cylinder 8 , Spray bar assembly 9, rotating shaft 10, bull gear 11, pinion 12, guide pulley 14, guide pulley shaft 15.

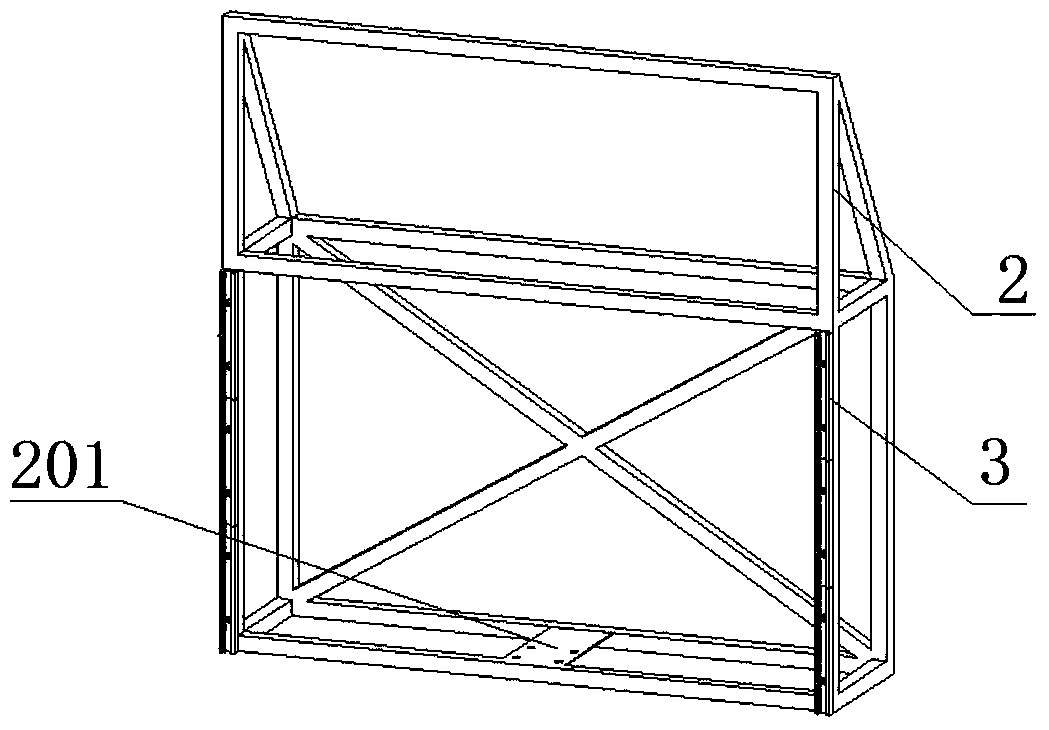

[0030] The structure of the height adjustment frame 7 is as Figure 4 As shown, it includes a main body 702, an installation platform 701 located on the upper part of the main body 702, a guide plate 703 located on both sides of the main body 702, and a rotating shaft seat hole 705 located at the bottom of the main body 702 and perpendicular to it. There is an arc-shaped guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com