Two-stage rolling rotor-type expander

A rolling rotor type and expander technology, which is applied in the direction of machines/engines, combined engines, rotary piston engines, etc., can solve problems such as the decrease of expander efficiency, reduce flow loss, reduce length and volume, and improve expansion efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

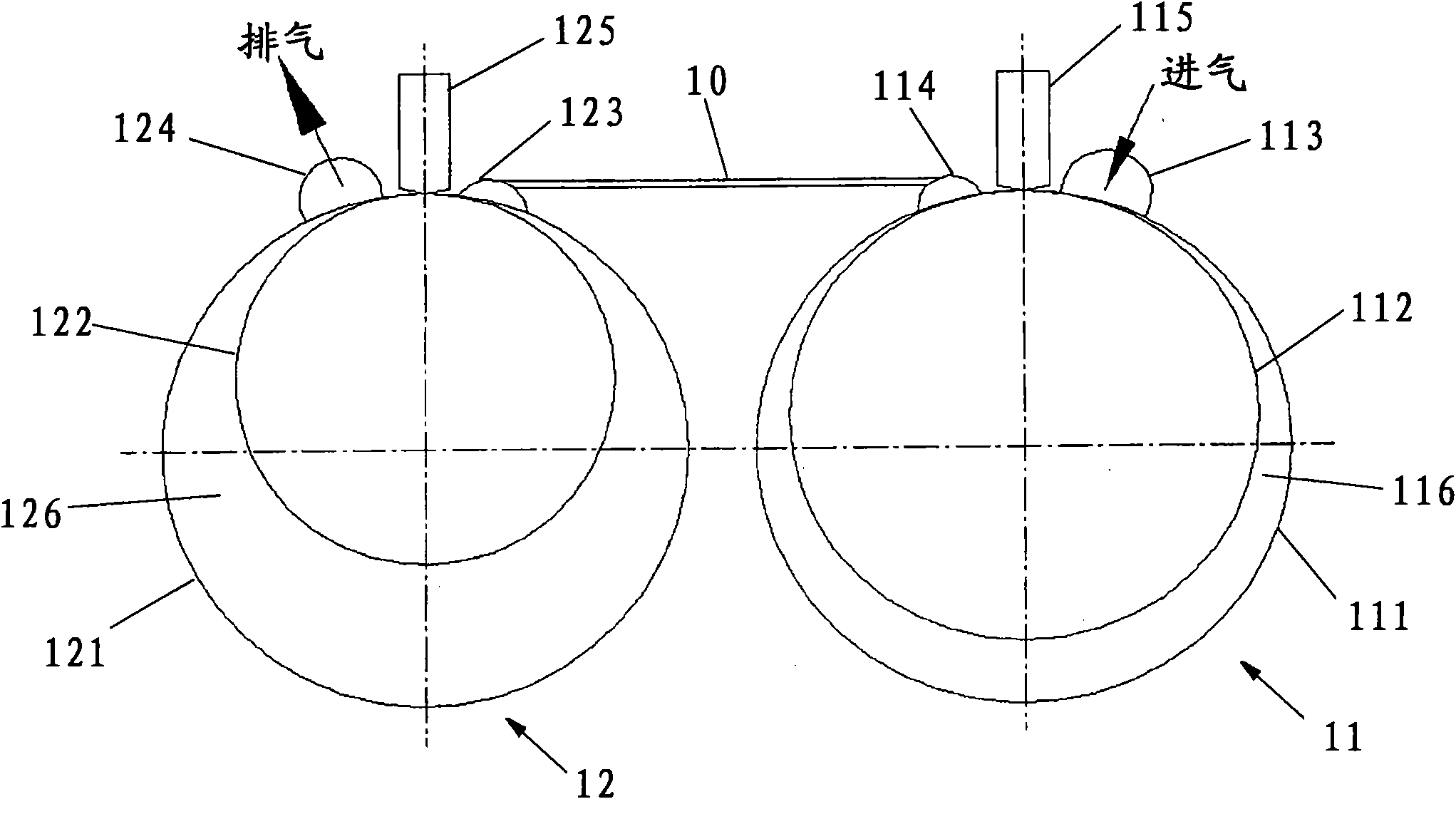

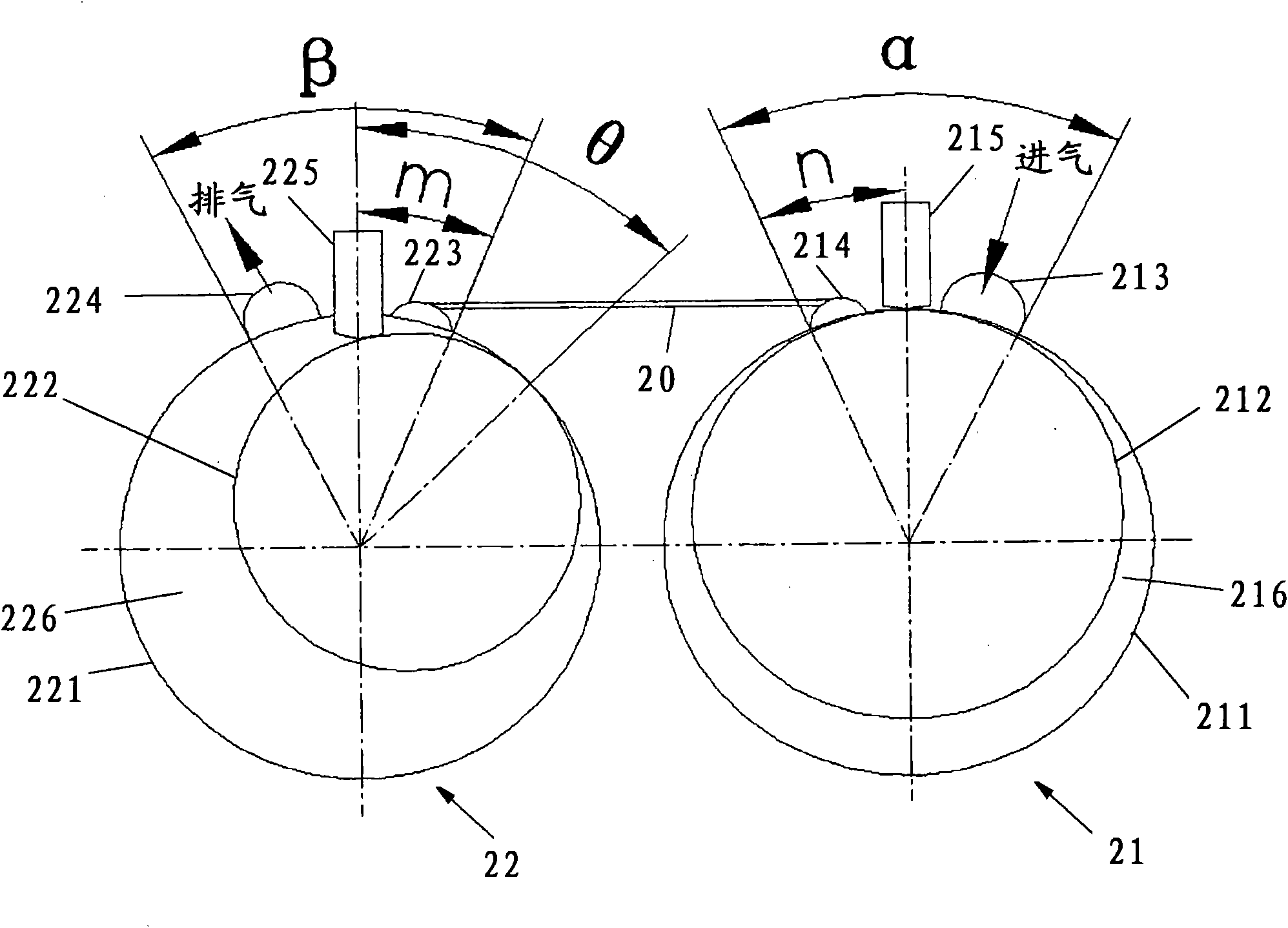

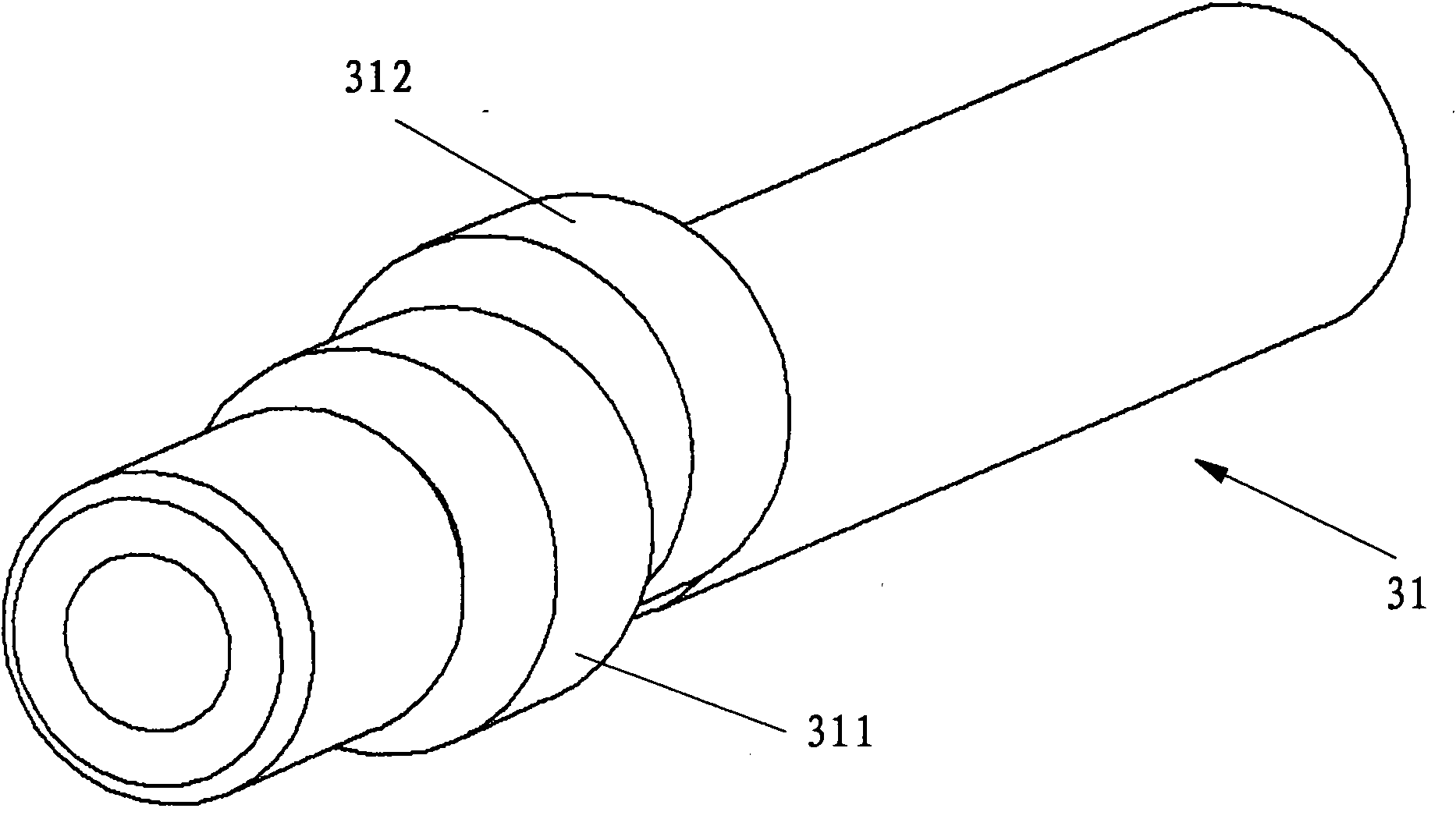

[0015] figure 2 shows a two-stage rolling rotor expander according to a first embodiment of the invention, image 3 The crankshaft in this two-stage rolling rotor expander is shown. The two-stage rolling rotor expander includes a first expansion unit 21 , a second expansion unit 22 , an intermediate plate between the first and second expansion units, and a crankshaft 31 shared by the first and second expansion units.

[0016] The first expansion unit 21 includes a first cylinder 211 with a first suction port 213 and a first exhaust port 214 , a first piston 212 , and an angle between the first suction port 213 and the first exhaust port 214 . The first blade 215 in. The first cylinder 211 and the first piston 212 define a first cavity 216 . The second expansion unit 22 includes a second cylinder 221 having a second suction port 223 and a second exhaust port 224 , a second piston 222 , and a The second blade 225 in. The second cylinder 221 and the second piston 222 define...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com