Vehicle seat frame

A seat frame and vehicle technology, which is applied to vehicle seats, movable seats, vehicle parts, etc., can solve the problems of shoulder seat belt anchors exerting large loads and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

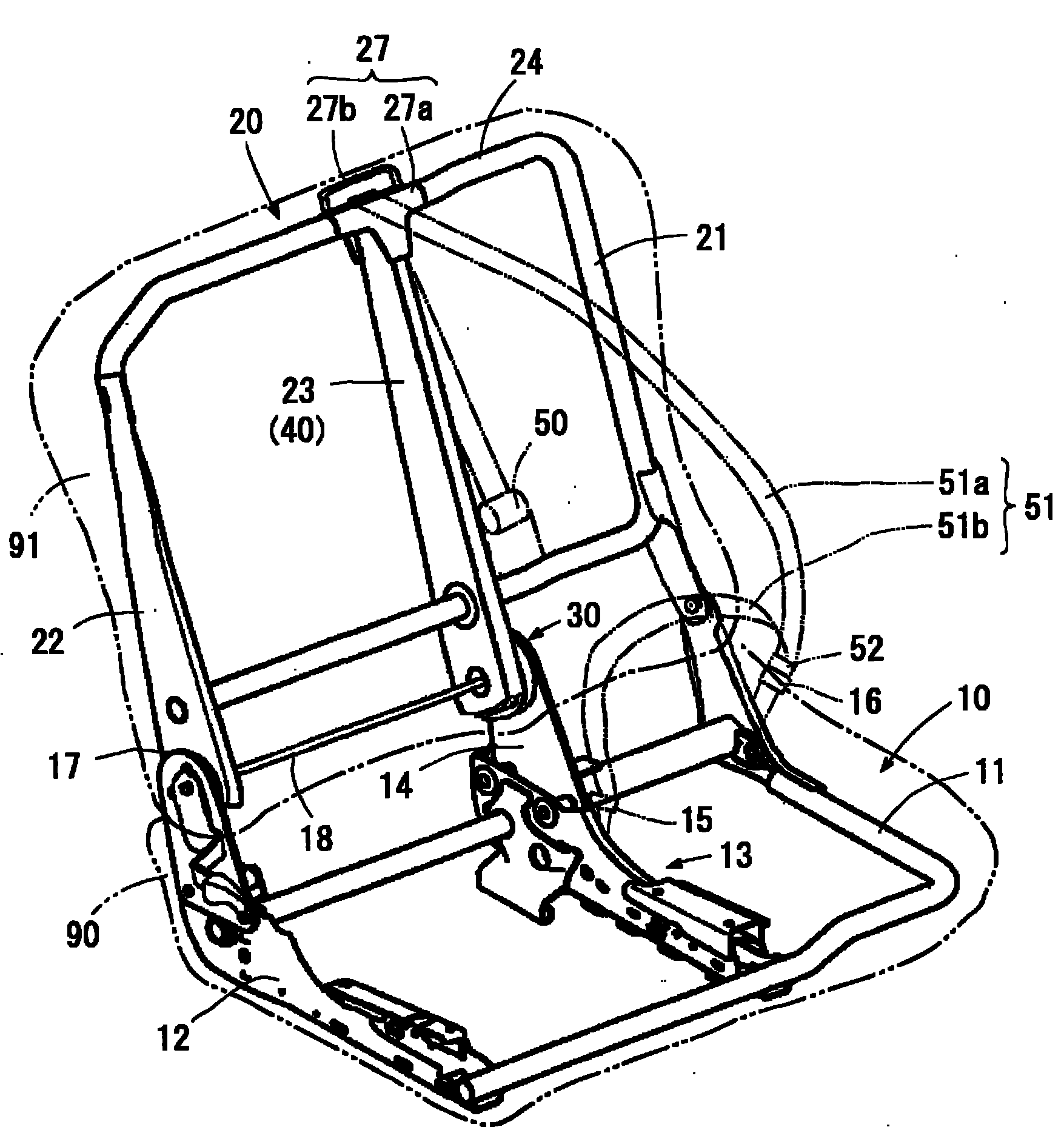

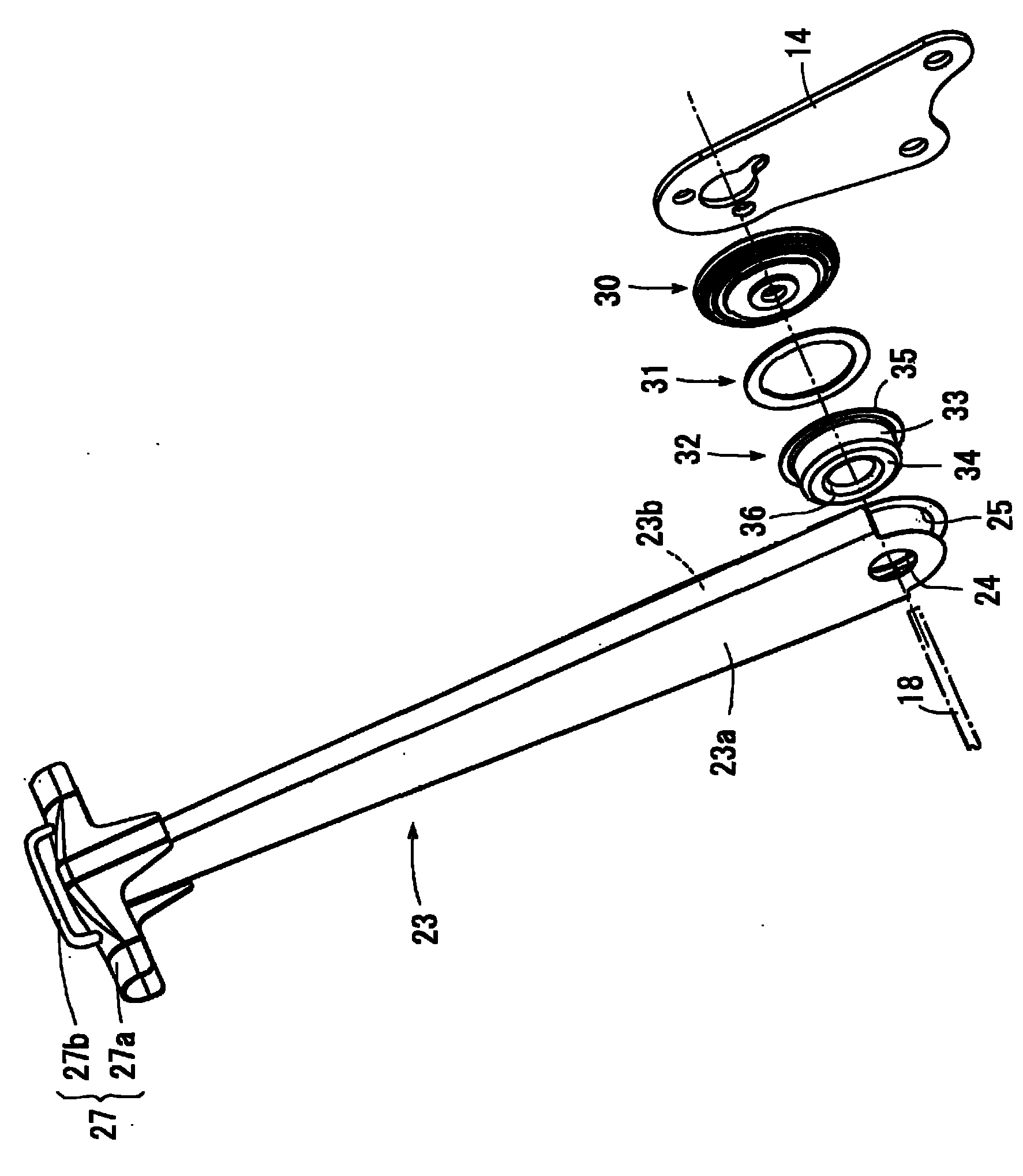

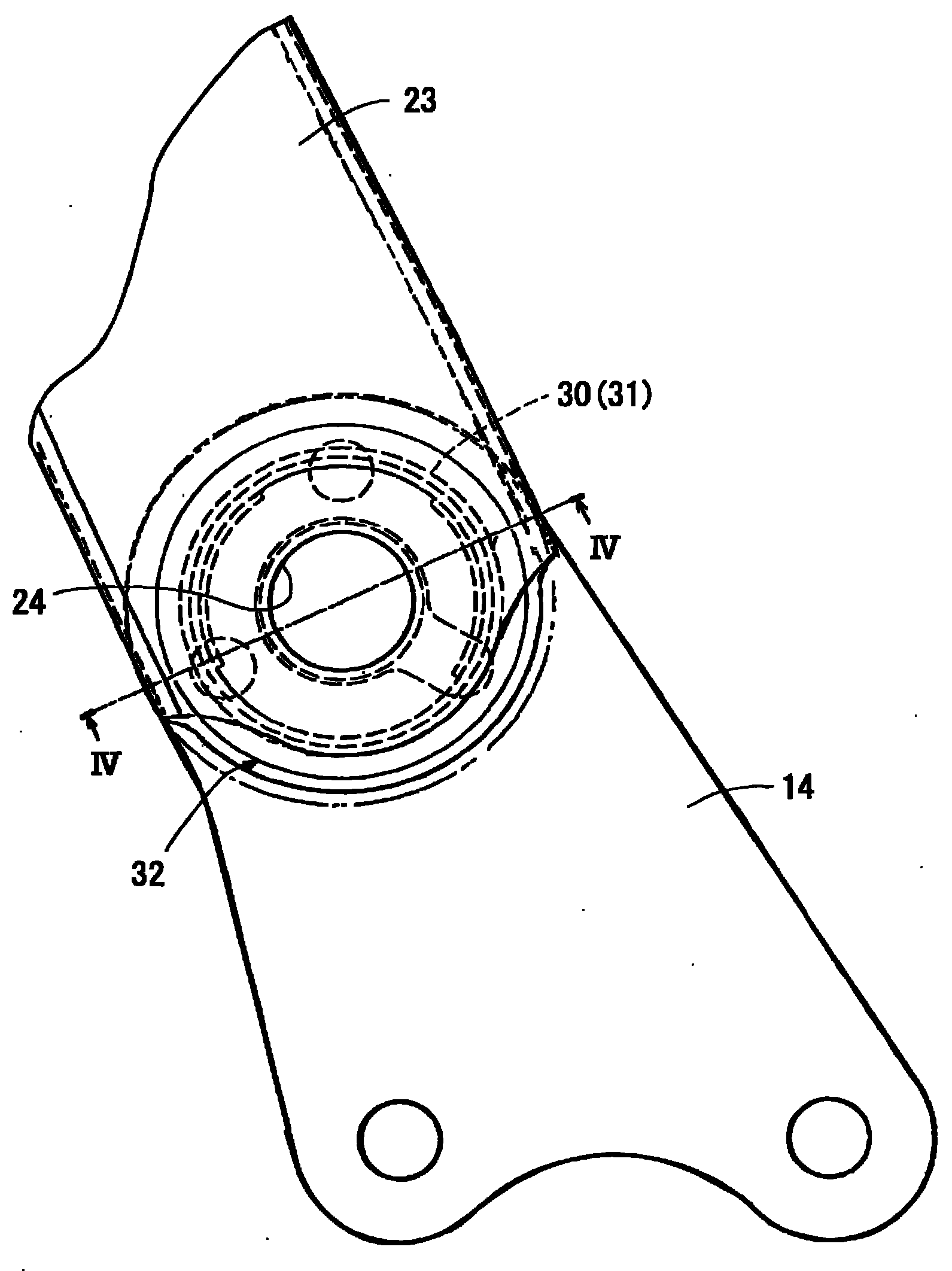

[0042] Hereinafter, Embodiments 1 to 3 in which the vehicle seat frame according to the present invention is embodied will be described with reference to the drawings. Such as figure 1 As shown, the vehicle seat frame according to Embodiment 1 includes: a seat cushion frame 10 supporting the seat cushion 90; a seat back frame 20 supporting the seat back 91; 91 is connected so as to be freely rotatable relative to the seat cushion 90, and to adjust the rotation angle of the seat back; The shoulder belt anchor 27 is composed of a joint portion 27a and a belt guide portion 27b.

[0043] Back side frames 21 and 22 are arranged at both ends of the seat back frame 20 , and a hollow back middle frame 23 in the shape of a rectangular column is arranged at the center. The upper ends of the two back side frames 21 and 22 are connected by an upper pipe 24, and the center part of the upper pipe 24 and the upper end of the back middle frame 23 are connected by a joint part 27a. The joi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com