Forming equipment of large size composite stringer

A composite material and large-size technology, which is applied in the field of improvement of large-size composite material long truss forming tooling, can solve the problems of difficult processing, high cost, and high scrap rate, so as to improve surface accuracy and pass rate, reduce manufacturing costs, The effect of reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

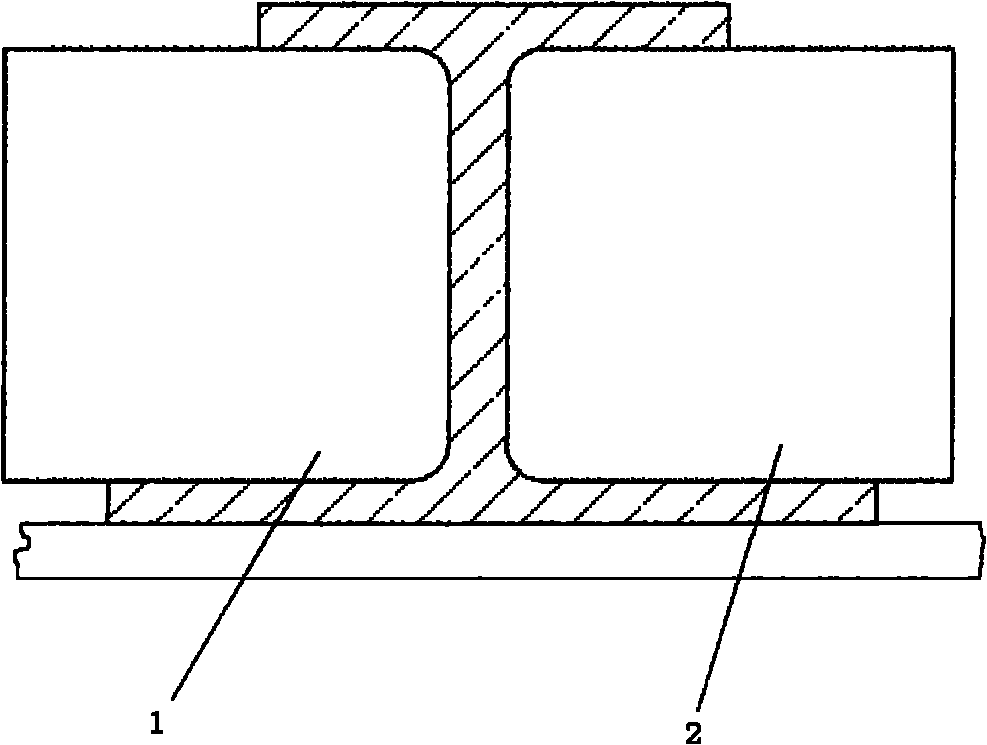

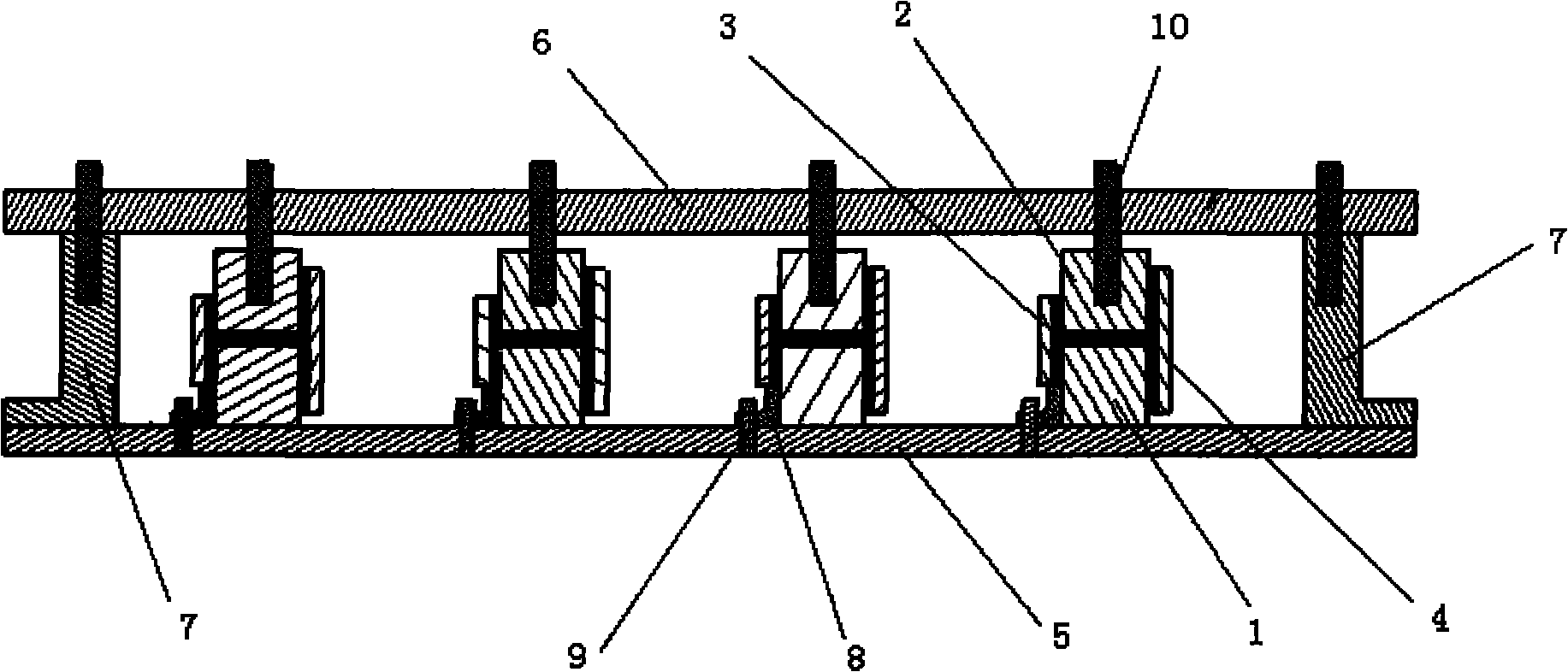

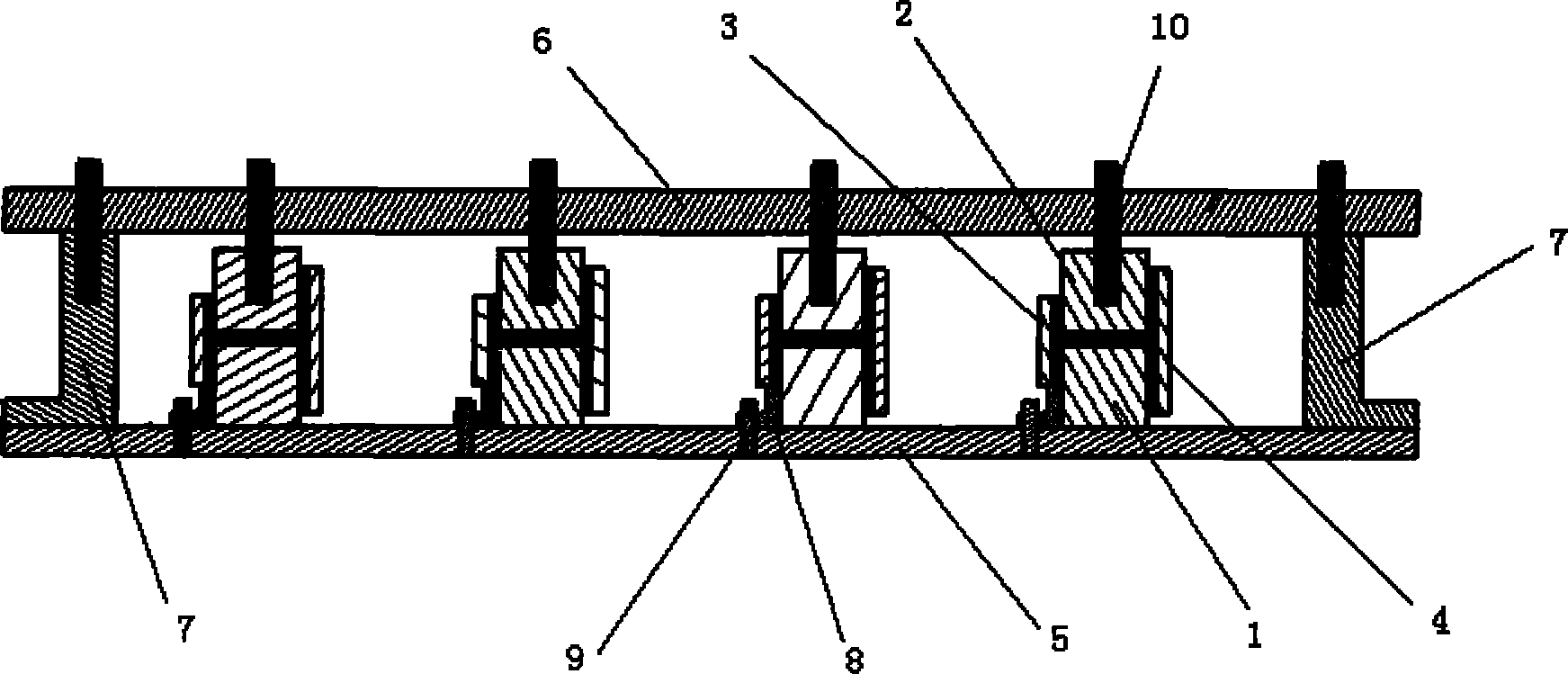

[0011]There are 8 prefabricated I-shaped composite material long stringers, each with a length of 10 meters. The upper and lower edges are curved, and the web is flat. The forming tooling to complete these stringers consists of a first mandrel and a second mandrel, the length of which is 10 meters, the right side of the first mandrel has the same profile as the left side of the stringer. surface; the upper surface of the first mandrel has the same profile as the lower surface on the left side of the upper edge of the stringer, the lower surface of the first mandrel has the same profile as the upper surface on the left side of the lower edge of the stringer, the first The right surface of the mandrel has the same profile as the left surface of the stringer web; the left side of the second mandrel has the same profile as the right side of the stringer; the upper surface of the second mandrel has the same profile as the stringer web The lower surface on the right side of the uppe...

Embodiment 2

[0013] There are 6 prefabricated inverted J-shaped composite material long stringers, each with a length of 8 meters. The upper and lower edges are curved, and the web is flat. The sectional shape of the stringer is an inverted J shape, and the forming tooling includes a first mandrel and a second mandrel, the lengths of the first mandrel and the second mandrel are equal to the length of the stringer, and the right side of the first mandrel has The same profile as the left side of the stringer; the lower surface of the first mandrel has the same profile as the upper surface on the left side of the lower edge of the stringer, and the right surface of the first mandrel has the same profile as the left side of the stringer web surface; the left side of the second mandrel has the same profile as the right side of the stringer; the upper surface of the second mandrel has the same profile as the lower surface on the right side of the upper edge of the stringer; the second mandrel Th...

Embodiment 3

[0015] There are 8 prefabricated inverted T-shaped composite material long stringers, each 10 meters long, with a curved lower edge and a flat web. The sectional shape of the long stringer is inverted T shape, and the forming tooling includes a first mandrel and a second mandrel, the length of the first mandrel and the second mandrel is 10 meters, and the right side of the first mandrel has a Same profile on the left side; the lower face of the first mandrel has the same profile as the upper face on the left side of the lower edge of the stringer, and the right face of the first mandrel has the same profile as the left face of the stringer web ; The left side of the second mandrel has the same profile as the right side of the stringer; the lower surface of the second mandrel has the same profile as the upper surface on the right side of the lower edge of the stringer, and the left surface of the second mandrel With the same profile as the right face of the stringer web. The e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com