Anti-leakage butterfly valve

A technology of anti-leakage and butterfly valves, which is applied in the direction of lifting valves, valve details, valve devices, etc., can solve the problems of untimely detection and small leakage of sanitary butterfly valves, and achieve the effect of flexible and convenient assembly, easy detection, and flexible rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

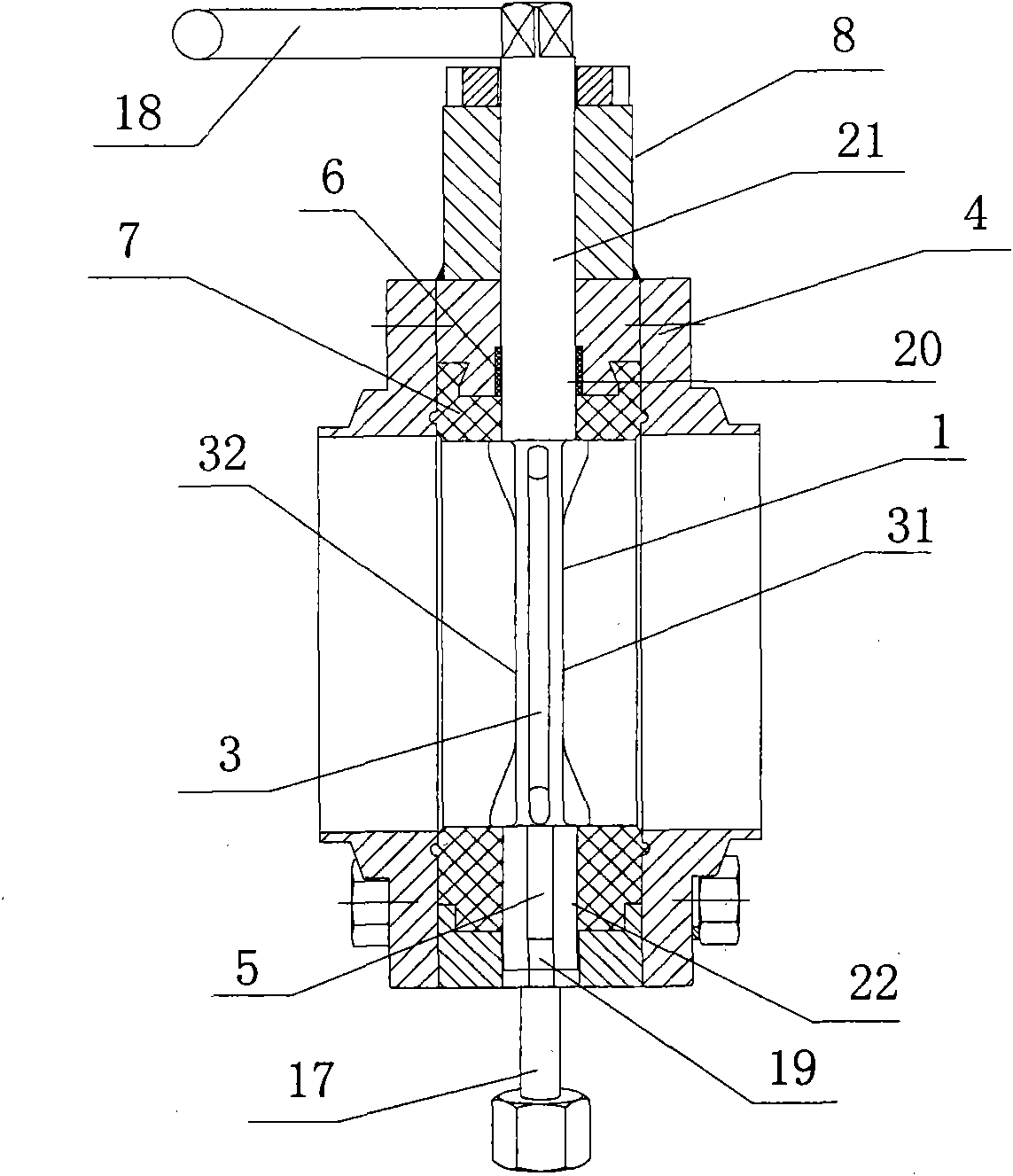

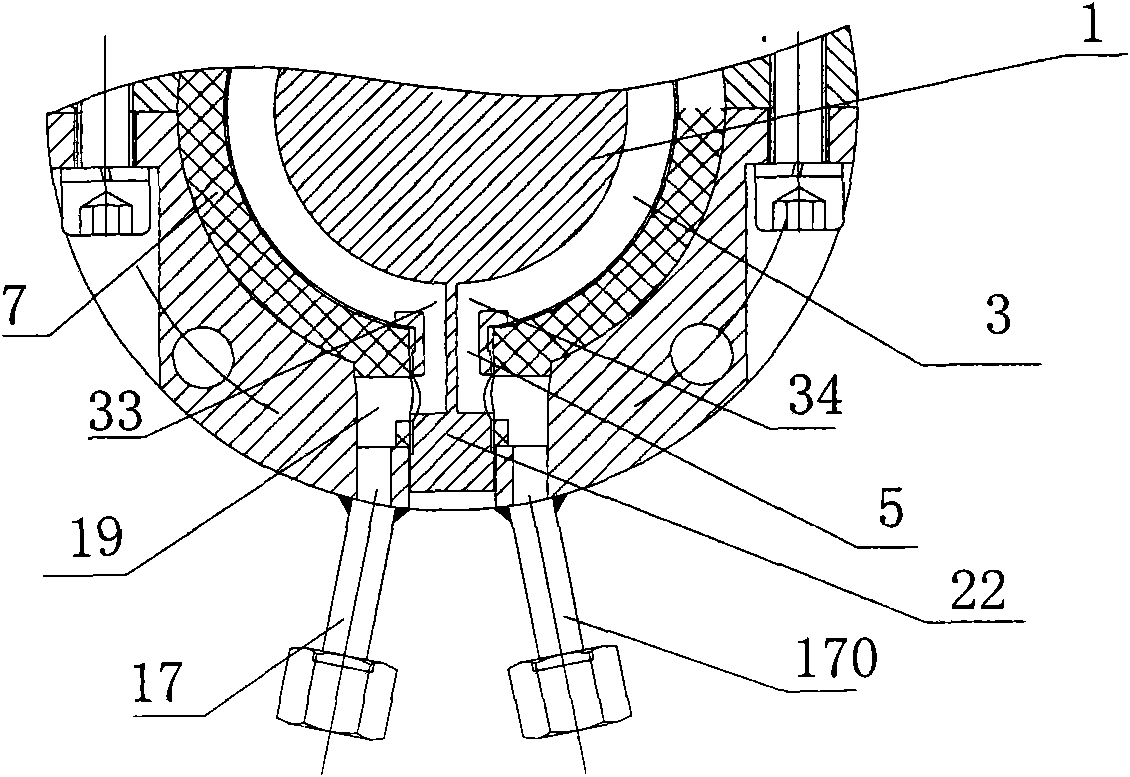

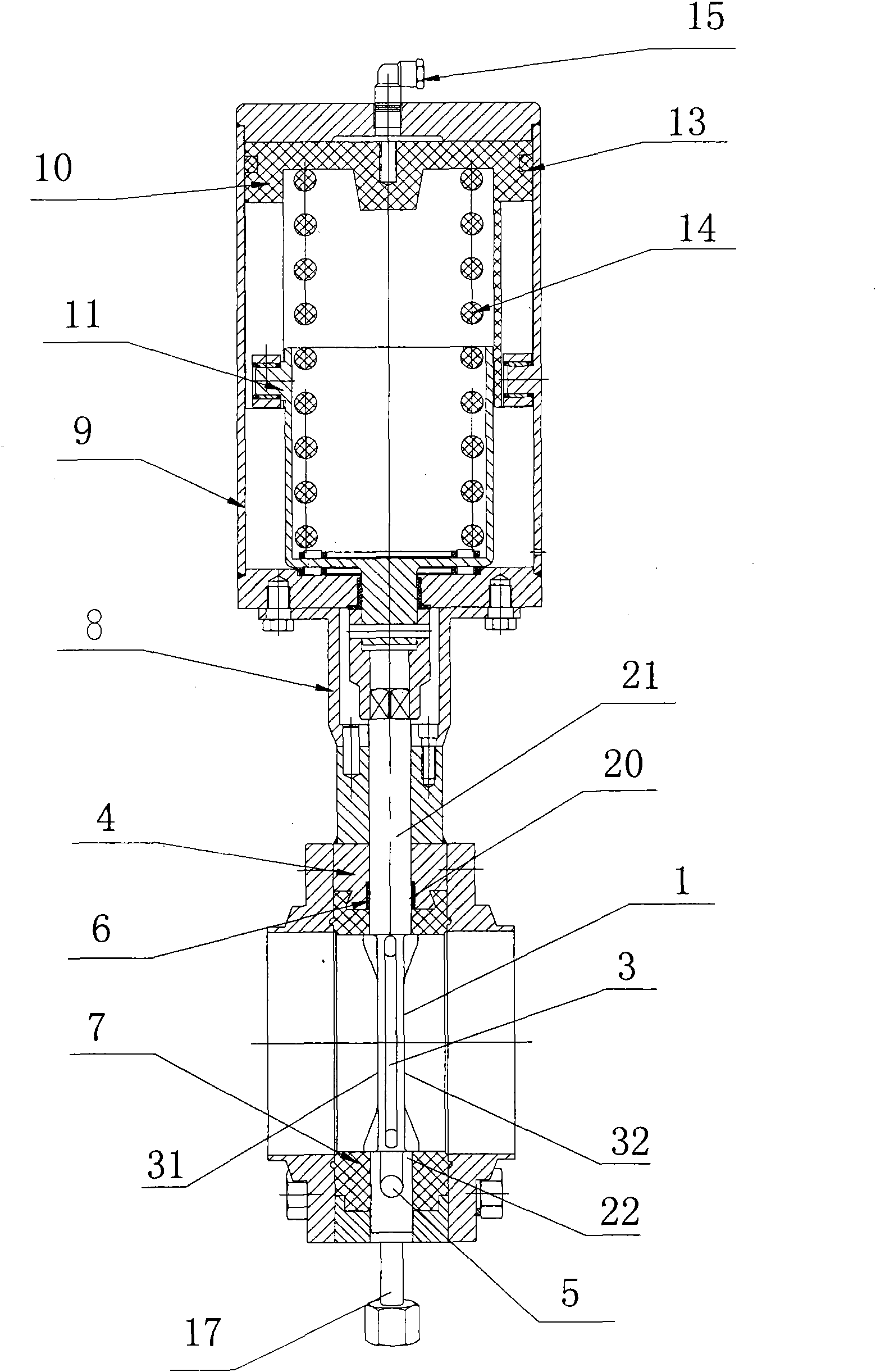

[0022] figure 1 A specific embodiment of the anti-leakage butterfly valve according to the present invention is given, Example 1, an anti-leakage butterfly valve, comprising: a valve body 4, an inner cavity is formed in the valve body 4; a butterfly plate 1, The butterfly plate 1 is arranged in the inner cavity of the valve body 4, and when the butterfly plate 1 is closed, its two end faces 31, 32 form a seal with the inner cavity; the valve shaft, the valve shaft and the The butterfly plate linkage, the valve shaft is arranged symmetrically along the radial direction of the butterfly plate, and is divided into two parts: the upper valve shaft 21 and the lower valve shaft 22, and the butterfly plate 1 is installed in the valve body 4 through the valve shaft In the cavity; the actuator, the actuator is connected with the upper valve shaft 21, the opening and closing of the butterfly plate 1 is realized by controlling the rotation of the upper valve shaft 21, and the actuator is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com