Transport roller, transport unit, and printing apparatus

A technology of conveying unit and conveying roller, applied in conveying unit, printing device, conveying roller field, can solve the problems of conveying speed, conveying fluctuation, conveying fluctuation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be described in detail below with reference to the drawings. In addition, in each of the drawings used in the following description, the ratio of each member is appropriately changed in order to make each member have a recognizable size.

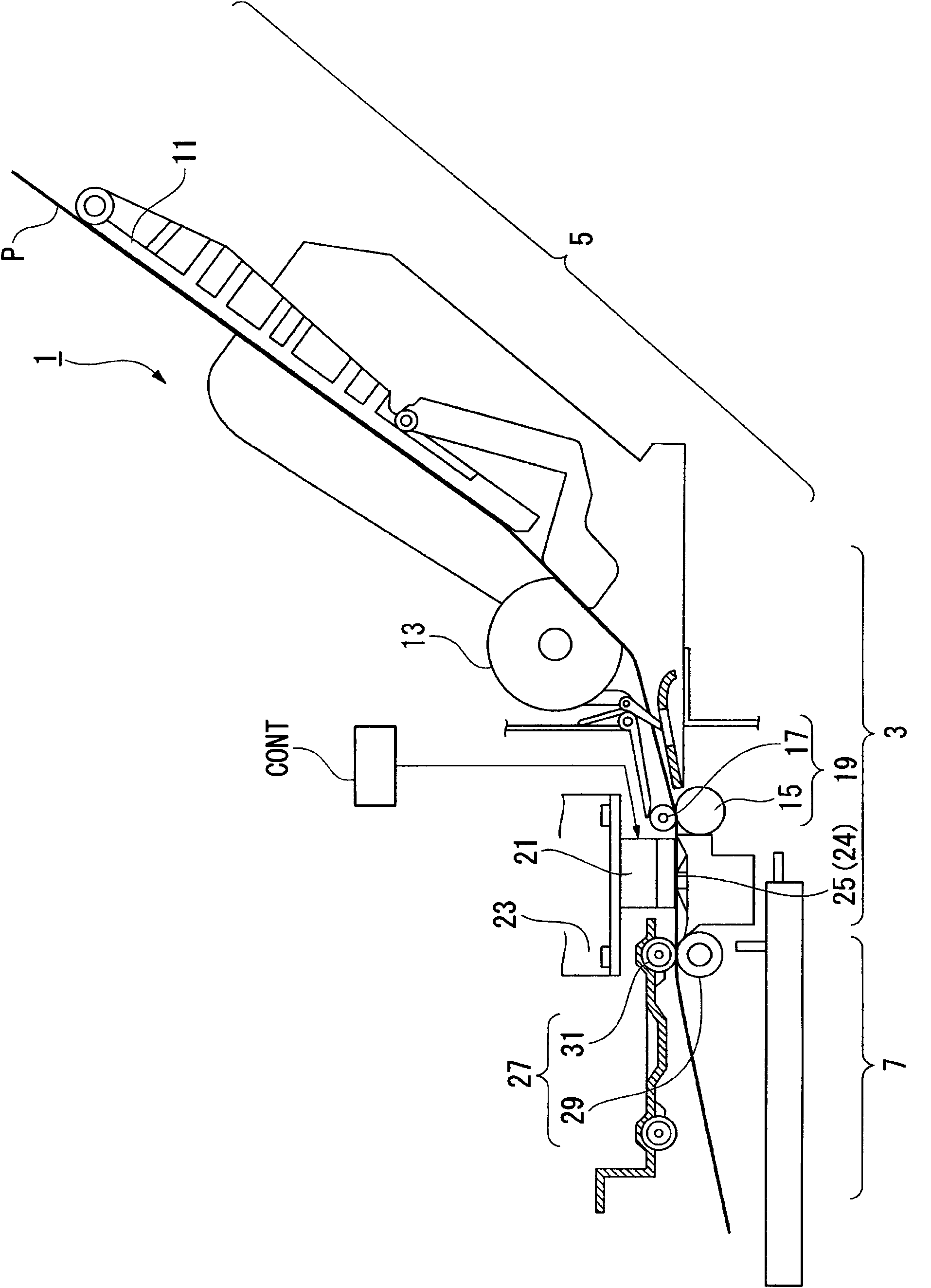

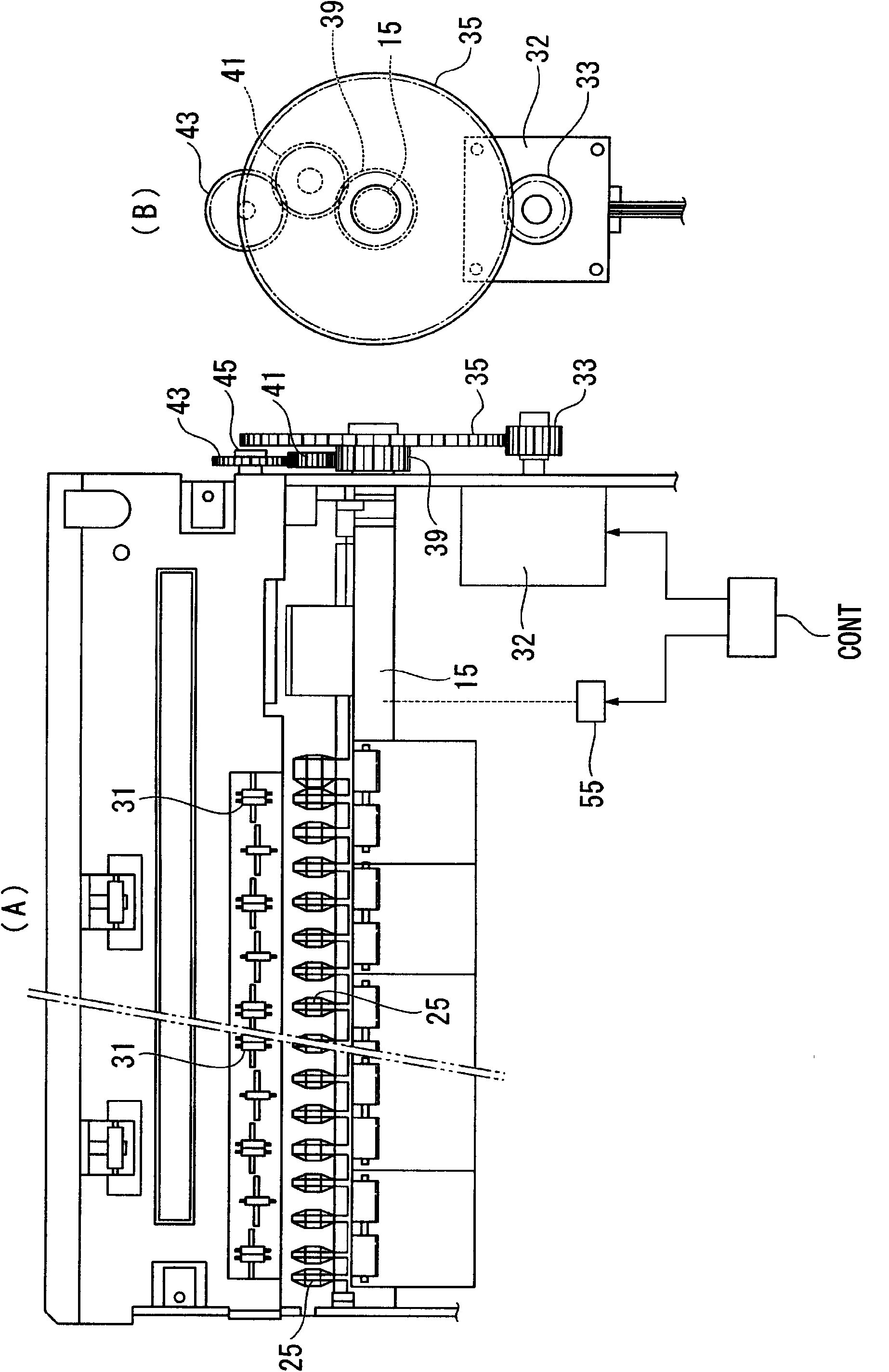

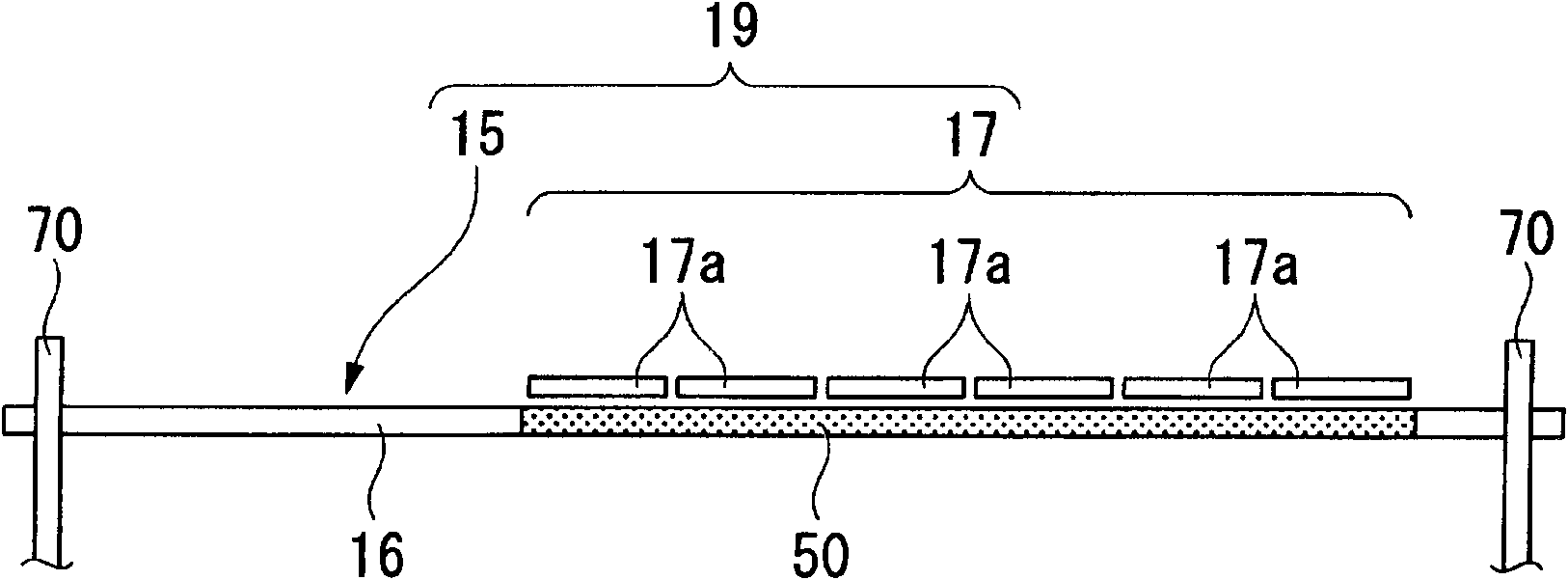

[0062] First, refer to figure 1 , figure 2 A description will be given of a printing device having the transport roller of the present invention. and, figure 1 Is a side cross-sectional view of the printing device (inkjet printer) with the conveying unit of the present invention, figure 2 (A) is a top view of the conveying unit part of the printing device, figure 2 (B) is a side view of the drive system of the printing device.

[0063] in figure 1 The symbol 1 is an inkjet printer in an embodiment of the printing device of the present invention. The inkjet printer 1 is configured to include a printer main body 3, a paper feed section 5 provided on the upper rear side of the printer main body 3, and a paper di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com