Laundry machine and device for producing mist

A technology of washing machine and air, applied in the field of washing machine, can solve the problems of inconvenient use and inability to take out clothes immediately

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

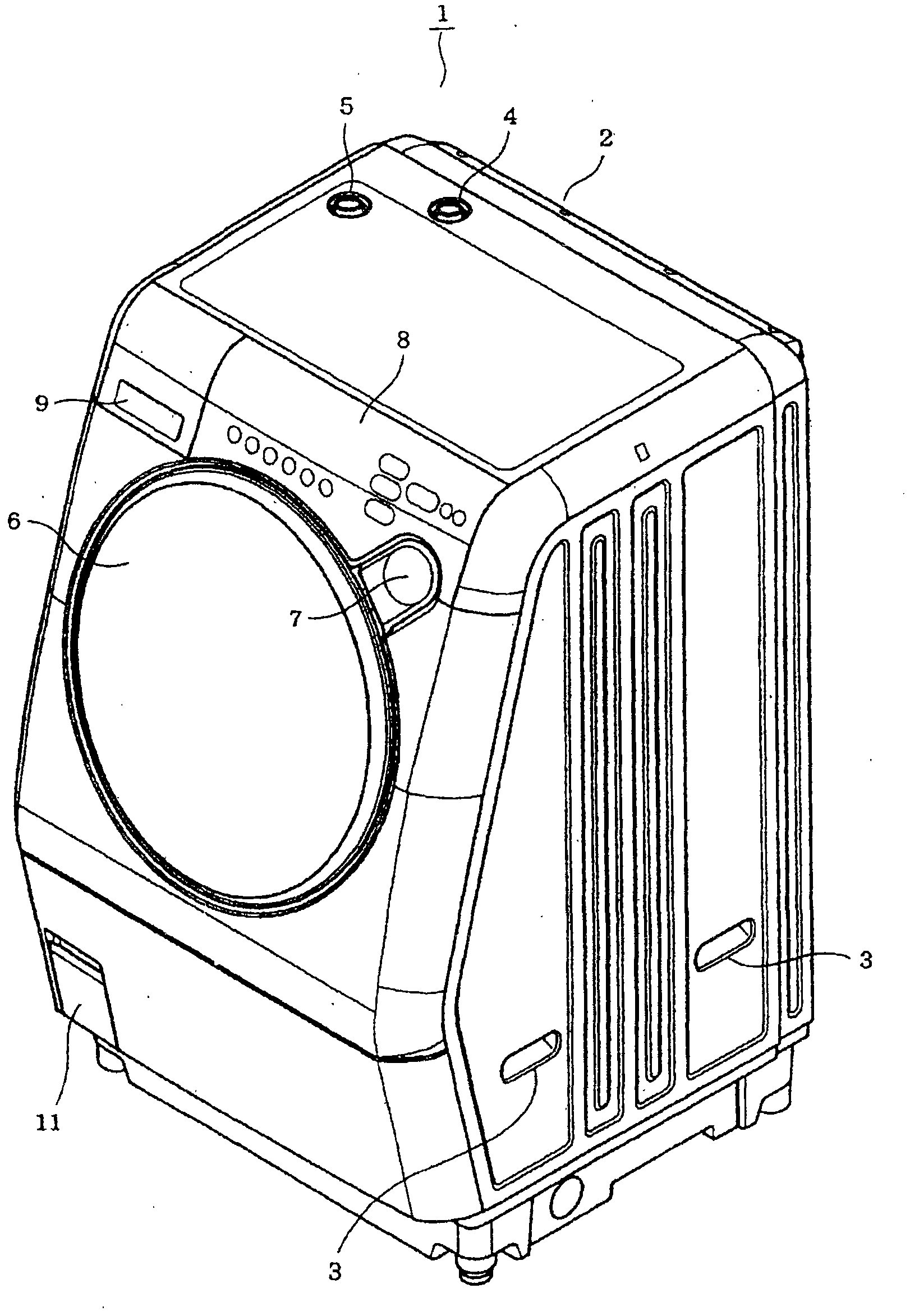

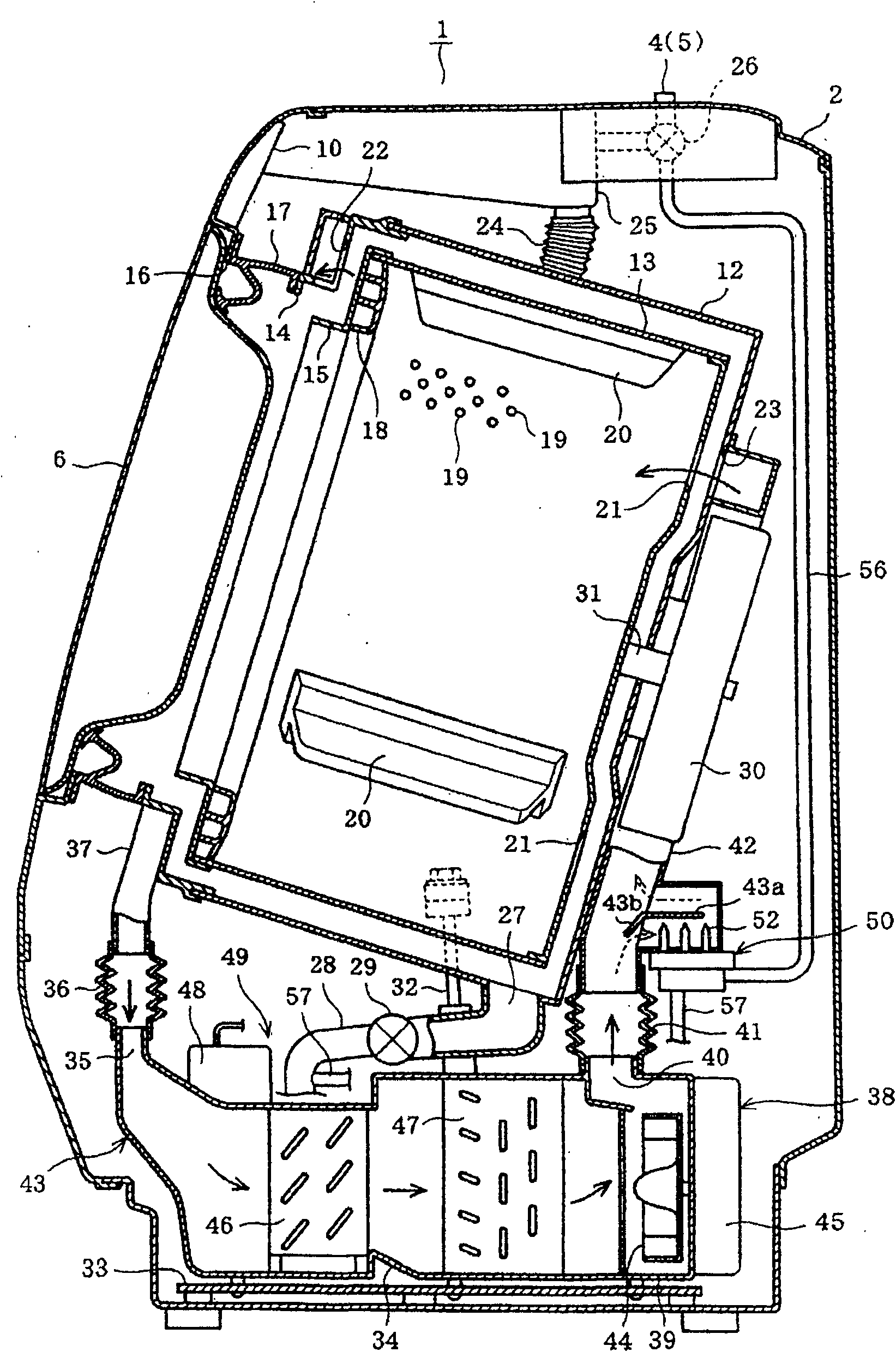

[0034] Below, refer to Figure 1 to Figure 4 The first embodiment of the present invention will be described. figure 2 It is a perspective view showing the overall appearance of the front-loading washing machine 1 . as it should figure 2 As shown, the frame body 2 constituting the outer shell of the washing machine 1 is formed in a substantially rectangular box shape whose entire surface slopes smoothly. On the left and right sides of the housing 2, handles 3 for moving the washing machine 1 and the like are provided. Furthermore, a water supply port 4 for tap water and a water supply port 5 for bath water are provided on the upper surface of the housing 2 .

[0035] In the front central portion of the housing 2, there is provided a substantially circular door 6 and an operation button 7 for opening the door 6. As shown in FIG. Furthermore, an operation panel 8 and a detergent input portion 9 are provided on the front upper portion of the housing 2 . The operation panel...

no. 2 Embodiment

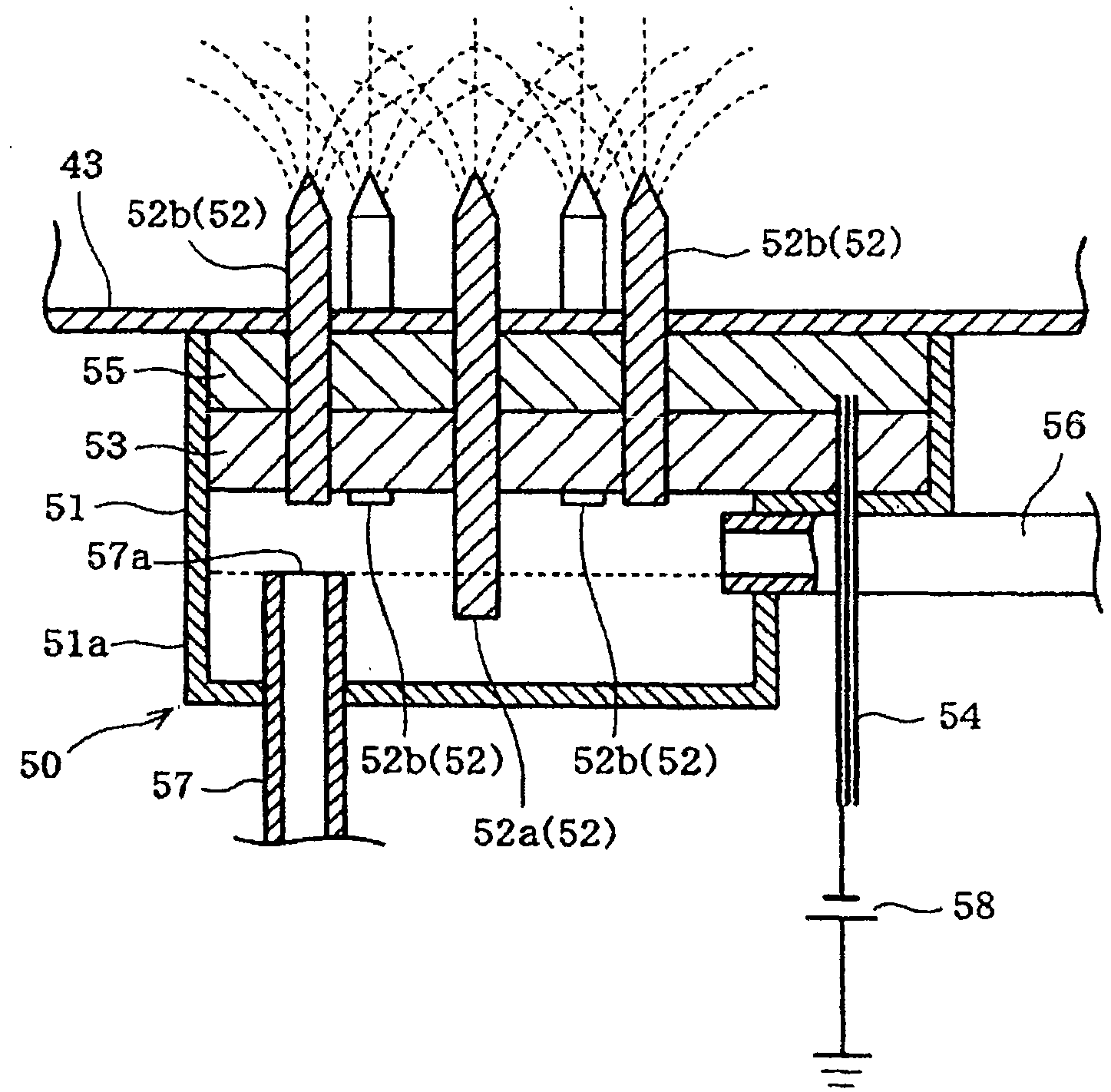

[0068] Next, a second embodiment of the present invention will be described. In this embodiment, platinum nano-colloid (Platinum Nano-colloid) is supported on the discharge electrode 52 of the mist generator. Platinum nanocolloids are supported on the discharge electrodes by, for example, immersing the discharge electrodes 52 in a treatment solution containing the platinum nanocolloids and firing them.

[0069] When platinum is reduced to a nanometer size (for example, a particle diameter of 2 to 5 nm) (at the time of micronization), the fine particles (platinum nanoparticles) have potential. And, when such platinum nanoparticles are given negative charges via the discharge electrode 52, the potential (oxidation-reduction potential) of the platinum nanoparticles becomes negative. When the air in the circulation air duct 43 comes into contact with the platinum nanoparticles whose oxidation-reduction potential becomes negative, the potential transfer from the oxygen molecules i...

no. 3 Embodiment

[0073] Next, a third embodiment of the present invention will be described. In this embodiment, the water storage material 53 in the mist generator is not made of polyurethane sponge but formed of fibrous ion exchange resin. Therefore, the part located outside the circulation air path 43 among the discharge electrodes 52 is covered with ion exchange resin. In this case, the ion exchange resin is a mixture of a strongly acidic ion exchange resin and a strongly basic ion exchange resin.

[0074] According to this configuration, before the tap water from the tap water supply port 4 is supplied to the discharge electrode 52, the mineral components contained in the tap water are adsorbed and removed by the ion exchange resin. Therefore, it is possible to prevent scale from accumulating on the discharge electrode 52 . Therefore, good water permeability of the discharge electrode 52 can be maintained, and the discharge electrode 52 can be appropriately negatively charged. Therefor...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap