Rapid feeding device of pressure filter

A feeding device and filter press technology, applied in the direction of filtration and separation, separation methods, chemical instruments and methods, etc., can solve the problems of low production efficiency, waste of energy, high production costs, etc., to improve production efficiency, reduce costs, Energy Saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

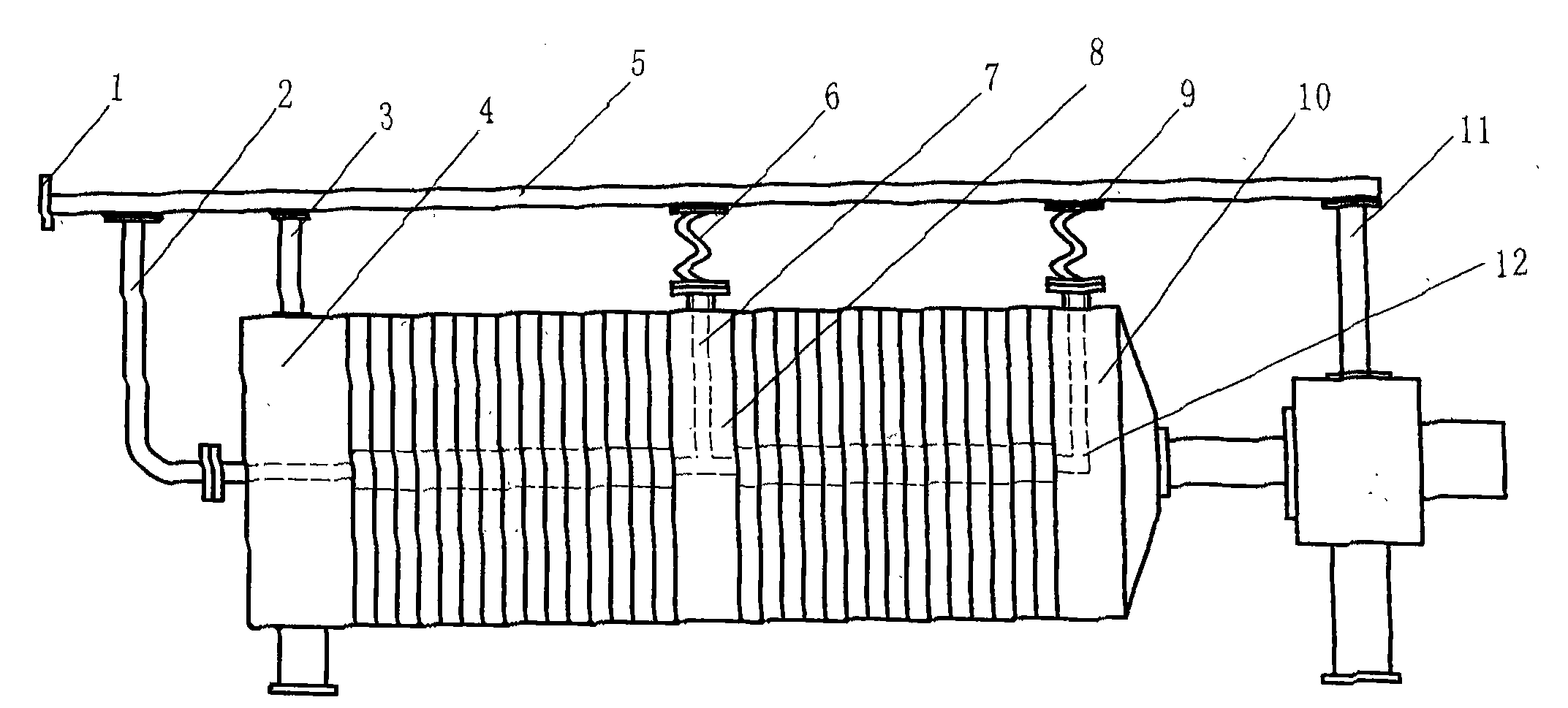

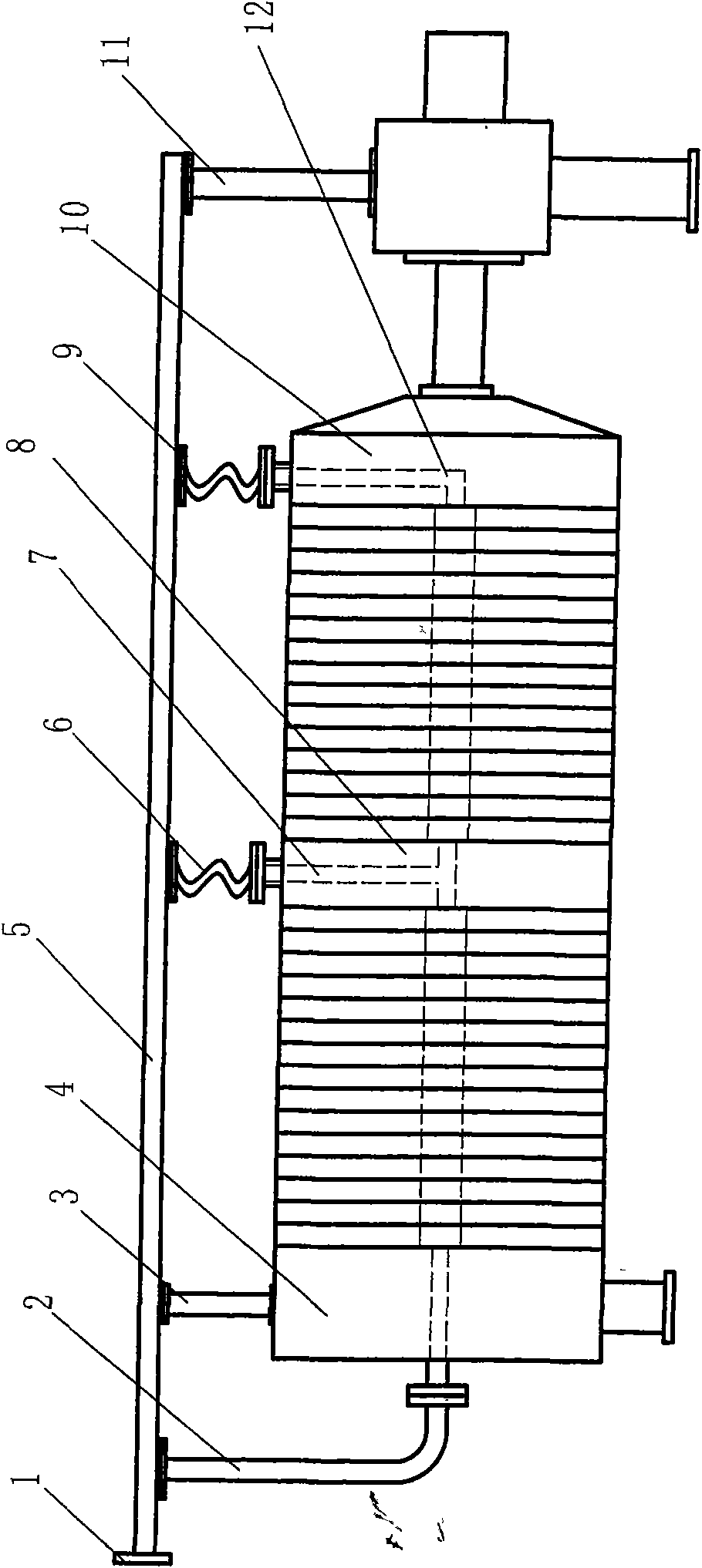

[0011] Please refer to Fig. 1, shown, a kind of filter press quick-feeding device provided by the present invention, feed main pipeline 5 is installed on the upper end of filter press, the material used is seamless steel pipe, and material is stainless steel or carbon structure Steel, the end surface of the main feeding pipe 5 is provided with an external flange 1 to connect with the external pipe, the main feeding pipe 5 is provided with a flange connecting the feeding pipe 2 and the rear end of the thrust plate 4, and a fixed bracket 3 is provided with flanges at both ends Connect the thrust plate 4 and the flange of the feed main pipe 5, the material used is seamless steel pipe or I-beam, the material is carbon structural steel, and the two ends of the frame support 11 are provided with flanges to connect the feed main pipe 5 and The flange of the oil cylinder base is made of seamless steel pipe or I-beam, and the material is carbon structural steel. The pipe flange 9 of the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap