Discontinuous type SMS nonwoven material and preparation method thereof

A technology of non-woven materials and manufacturing methods, applied in non-woven fabrics, textiles, papermaking, medical science, etc., can solve problems such as complex procedures, high costs, and stripping, and achieve the goal of overcoming complex processes, low production costs, and easy realization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The nonwoven material of "SMMS"+"SS"+"SMMS" structure and its manufacturing method:

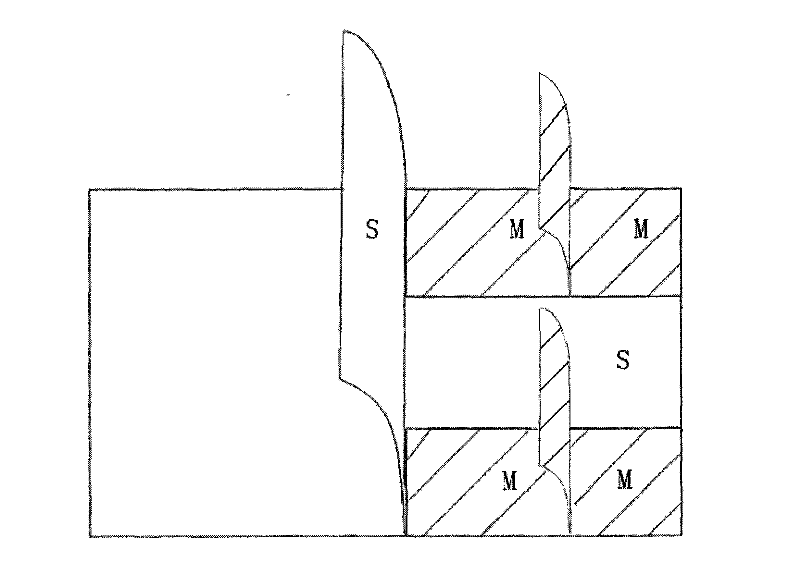

[0028] Such as figure 1 As shown, the process equipment includes the first spunbond equipment 1 and the second spunbond equipment 2, the first meltblown equipment 3 and the second meltblown equipment 4; the first spunbond equipment spins to form the first spunbonded fiber web 5, The second spunbond equipment spinning forms the second spunbond fiber web 6; the first melt-blown fiber web 7 formed by the first melt-blown equipment spinning, and the second melt-blown fiber web 8 formed by the second melt-blown equipment spinning; The first spunbonded fiber web, the first melt-blown fiber web, the second melt-blown fiber web and the second spunbond fiber web are laminated and hot-rolled by a hot rolling mill to form an SMMS spunmelt nonwoven fabric 9 . Among them, the first and second melt-blown equipment are composed of multiple small-width melt-blown equipment arranged at certain interva...

Embodiment 2

[0030] The nonwoven material and manufacturing method of the "SSS"+"SMSMS"+"SSS" structure of this example:

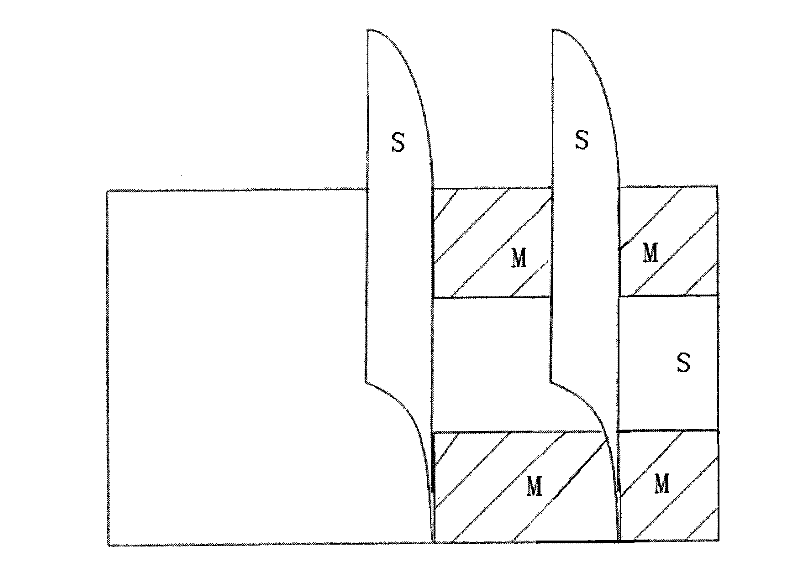

[0031] refer to figure 1 As shown, on the basis of embodiment 1, the third spunbond equipment is installed between the first and second meltblown equipment, and the third spunbond equipment spins to form the third spunbonded fiber web; the first spunbond The bonded fiber web, the first melt-blown fiber web, the third spunbond fiber web, the second melt-blown fiber web and the second spunbond fiber web are bonded to form a discontinuous spunmelt nonwoven fabric of SMSMS structure, that is, according to "SSS "+"SMSMS"+"SSS"+...+"SMSMS"+"SSS"+"SMSMS" regular arrangement. Width can be set as required. can be cut into image 3 As shown in the small width, the material after slitting has SMSMS structure on both sides, and the middle material is SSS structure.

Embodiment 3

[0033] The nonwoven material and manufacturing method of the "SS"+"SMMMS"+"SS" structure in this example:

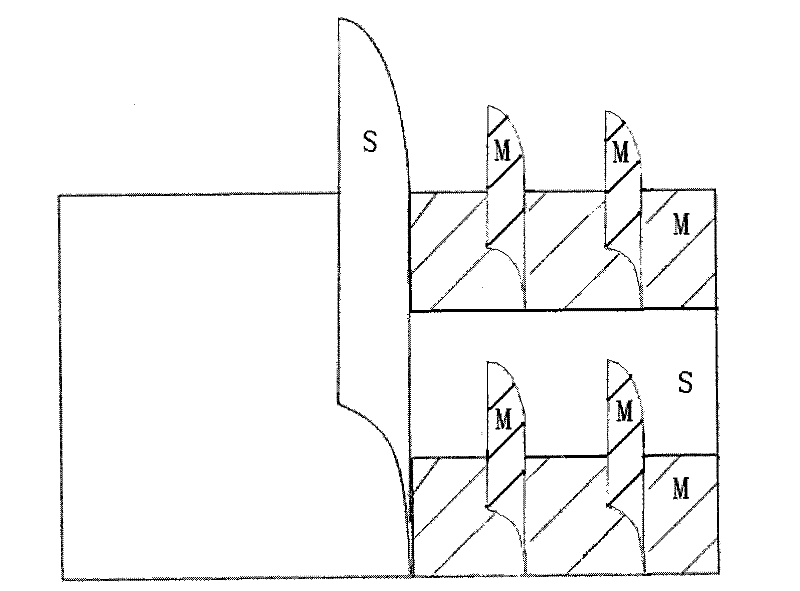

[0034] refer to figure 1 As shown, on the basis of Example 1, the third melt-blown equipment is installed between the first and second melt-blown equipment, and the third melt-blown fiber web formed by the spinning of the third melt-blown equipment; The spunbonded fiber web, the first meltblown fiber web, the third meltblown fiber web, the second meltblown fiber web and the second spunbond fiber web are bonded to form a discontinuous spunmelt nonwoven fabric of SMMMS structure, that is, according to " SS"+"SMMMS"+"SS"+...+"SMMMS"+"SSS"+"SMMMS" are arranged regularly. Width can be set as required. can be cut into Figure 4 In the small width shown, the material after slitting is SMMMS structure on both sides, and the middle material is SS structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com