Preparation method and application of composite non-woven fabric

A technology of non-woven fabrics and composite fiber webs, which is applied in non-woven fabrics, textiles, and papermaking, and can solve the problems of fiber electrostatic non-woven fabrics, immature technology, and insufficient softness and comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

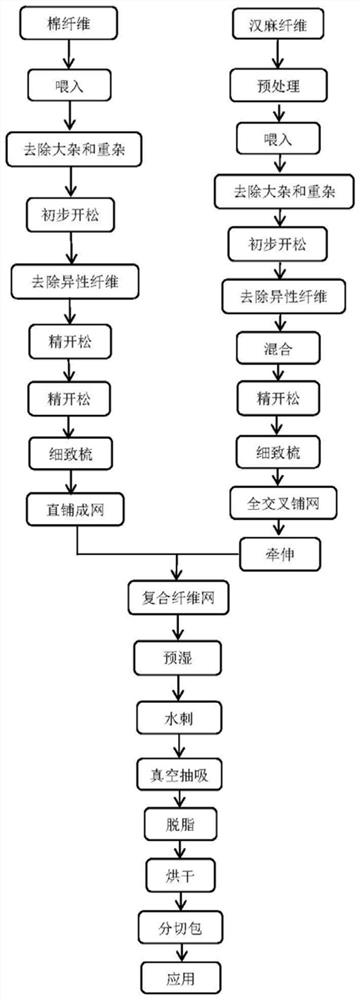

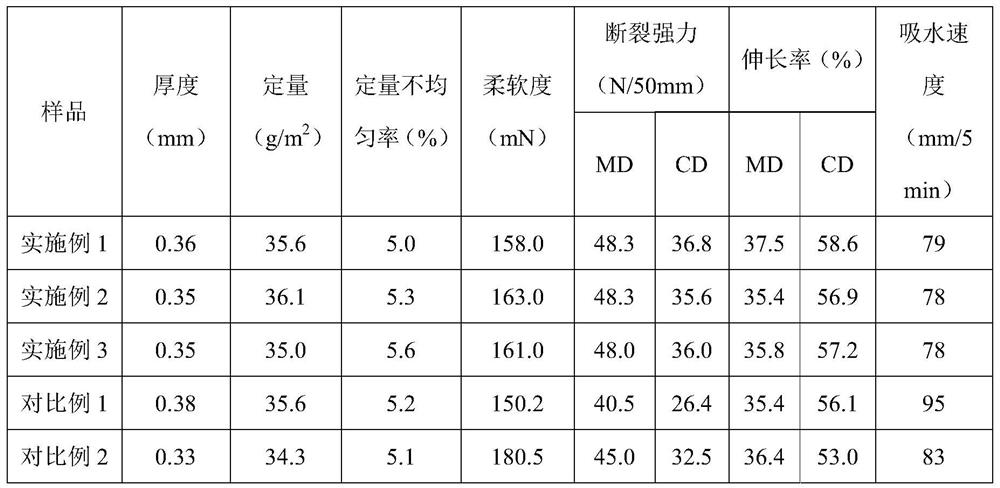

[0074] Embodiment 1 A kind of preparation method of spunlace nonwoven fabric

[0075] (1) Preparation of cotton fiber web

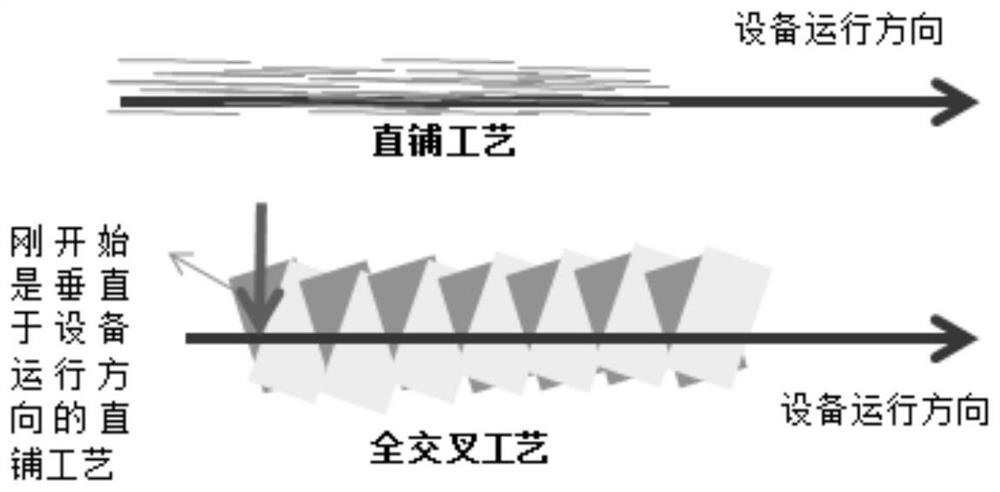

[0076] 100% natural cotton fibers are picked up and fed by the disc bale grabber, and transported to the JWF1011 multi-functional separator by airflow to remove large and heavy impurities in the cotton fibers, and then transported to the JWF1012 uniaxial flow opener for preliminary opening , the cotton flow after opening passes through the elf 8 foreign fiber machine to remove the foreign fibers in the cotton fiber, and after being mixed by the JWF1022 multi-compartment blending machine, it is sent to the JWF1124 fine cotton opener to finely open the cotton flow and remove fine impurities , into the ZWF1206 pre-carding machine for careful carding. After the carding is completed, it is sent to the ZGB1026 cotton storage box, the pressure in the cotton storage box is 880Pa, the ZGB1213 carding machine is evenly formed into a web, the feeding speed of the c...

Embodiment 2

[0091] Embodiment 2 A kind of preparation method of spunlace non-woven fabric

[0092] (1) Preparation of cotton fiber web

[0093] 100% natural cotton fibers are picked up and fed by the disc bale grabber, and transported to the JWF1011 multi-functional separator by airflow to remove large and heavy impurities in the cotton fibers, and then transported to the JWF1012 uniaxial flow opener for preliminary opening , the cotton flow after opening passes through the elf 8 foreign fiber machine to remove the foreign fibers in the cotton fiber, and after being mixed by the JWF1022 multi-compartment blending machine, it is sent to the JWF1124 fine cotton opener to finely open the cotton flow and remove fine impurities , into the ZWF1206 pre-carding machine for careful carding. After the carding is completed, it is sent to the ZGB1026 cotton storage box, the pressure in the cotton storage box is 850Pa, the ZGB1213 carding machine is evenly formed into a web, the feeding speed of the ...

Embodiment 3

[0108] Embodiment 3 A kind of preparation method of spunlace nonwoven fabric

[0109] (1) Preparation of cotton fiber web

[0110] 100% natural cotton fibers are picked up and fed by the disc bale grabber, and transported to the JWF1011 multi-functional separator by airflow to remove large and heavy impurities in the cotton fibers, and then transported to the JWF1012 uniaxial flow opener for preliminary opening , the cotton flow after opening passes through the elf 8 foreign fiber machine to remove the foreign fibers in the cotton fiber, and after being mixed by the JWF1022 multi-compartment blending machine, it is sent to the JWF1124 fine cotton opener to finely open the cotton flow and remove fine impurities , into the ZWF1206 pre-carding machine for careful carding. After the carding is completed, it is sent to the ZGB1026 cotton storage box, the pressure in the cotton storage box is 900Pa, the ZGB1213 carding machine is evenly formed into a web, the feeding speed of the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com