Trefoil bevel gear pair

A technology of bevel gear pair and bevel gear, applied in the field of three-blade bevel gear pair transmission mechanism, can solve problems such as analysis and design calculation methods that cannot be realized and have no practicability

Active Publication Date: 2010-08-25

CHONGQING UNIV

View PDF0 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Due to the complexity of the pitch curve of non-conical gears, there is no practical analysis and design calculation method for the research of non-conical gear pair transmission mechanisms, which has become an obstacle to the manufacture and application of non-conical gears. Therefore, the design of non-conical gears is an urgent problem to be solved. the puzzle

In order to solve the above problems, a design of non-conical gears such as oval bevel gear pairs has appeared. However, these gear meshing pairs can only realize two-cycle variable transmission ratio transmission, which can only be used in specific occasions. For some needs The application of three-cycle variable transmission ratio transmission cannot be realized

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

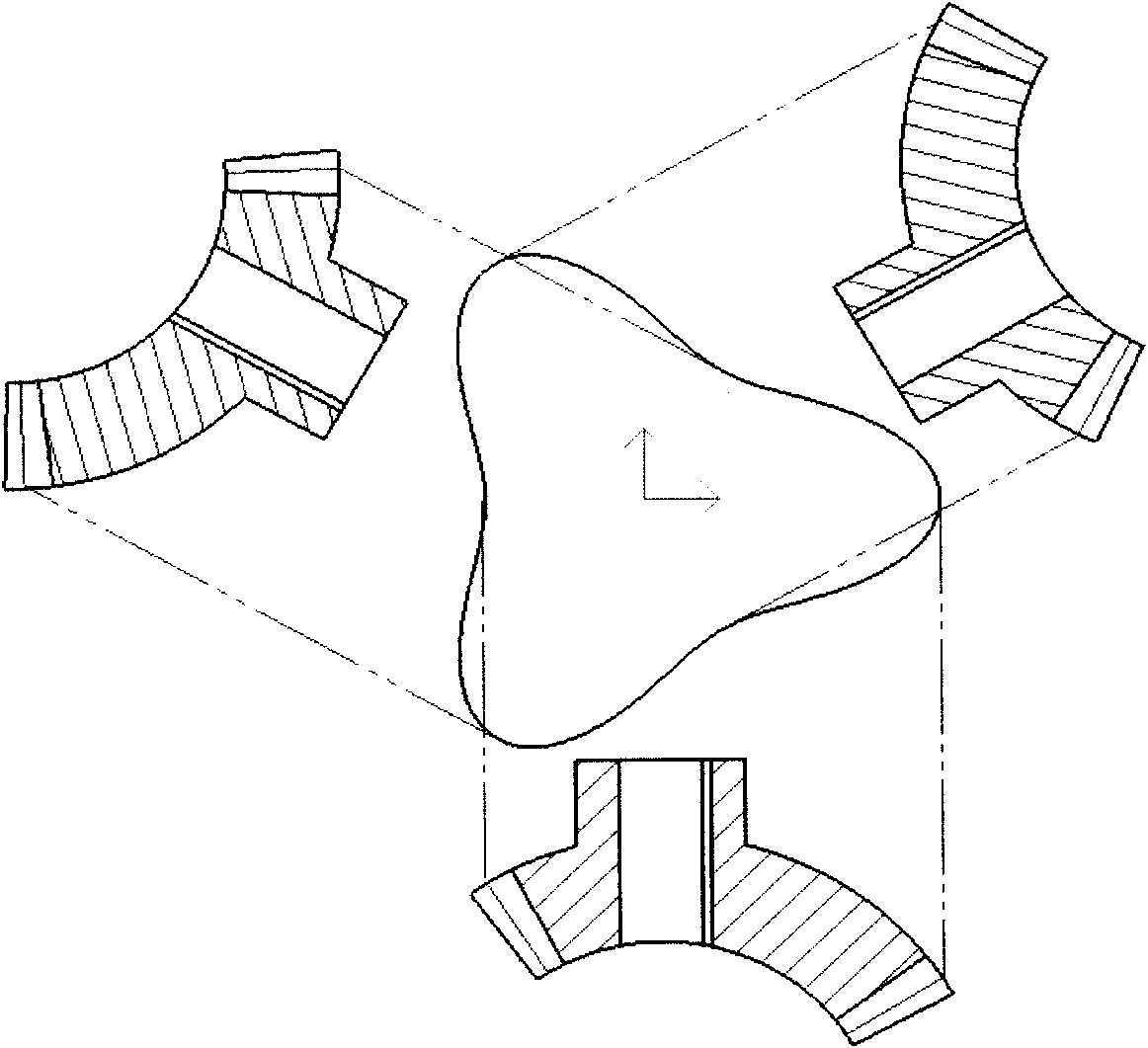

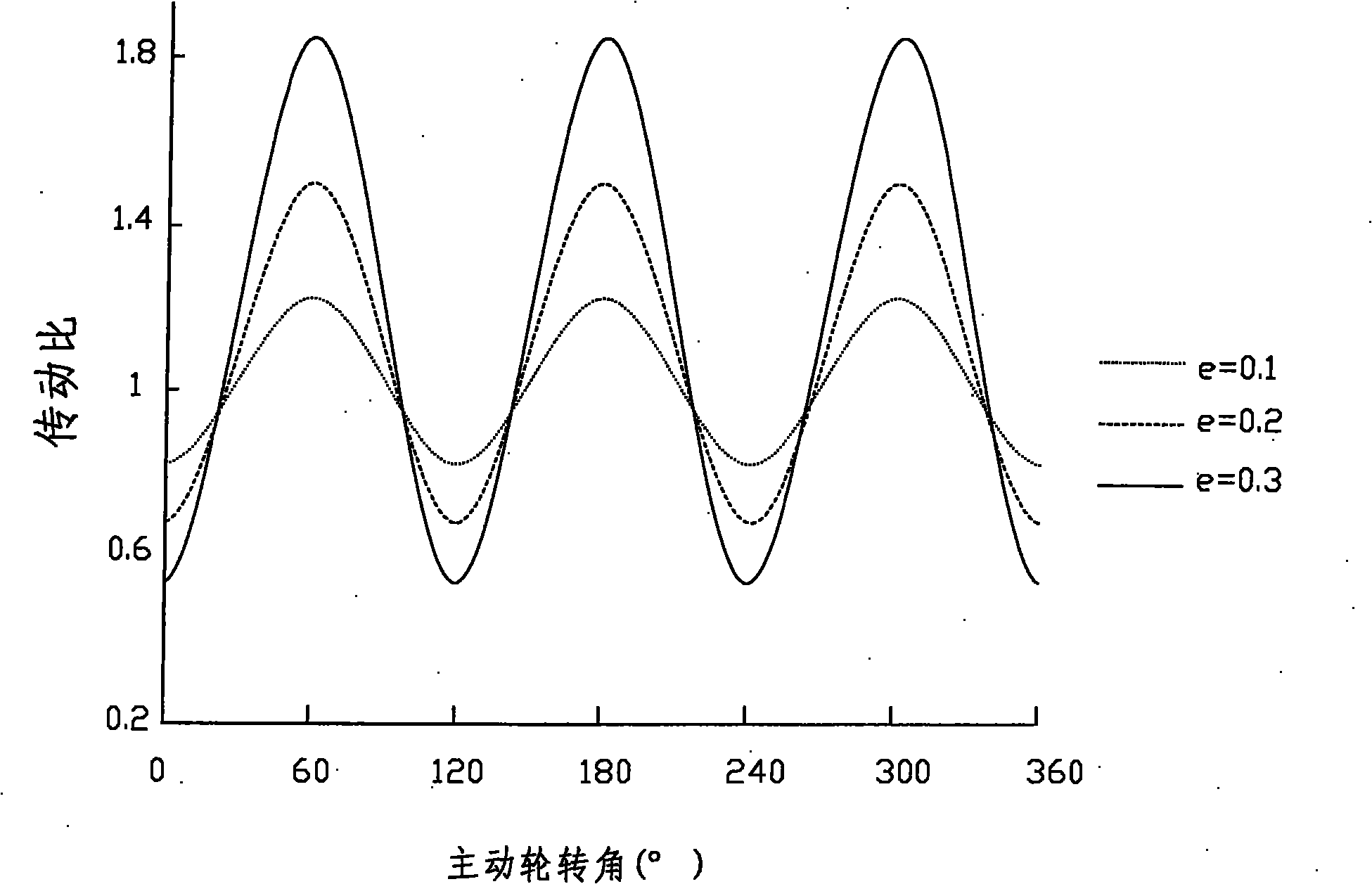

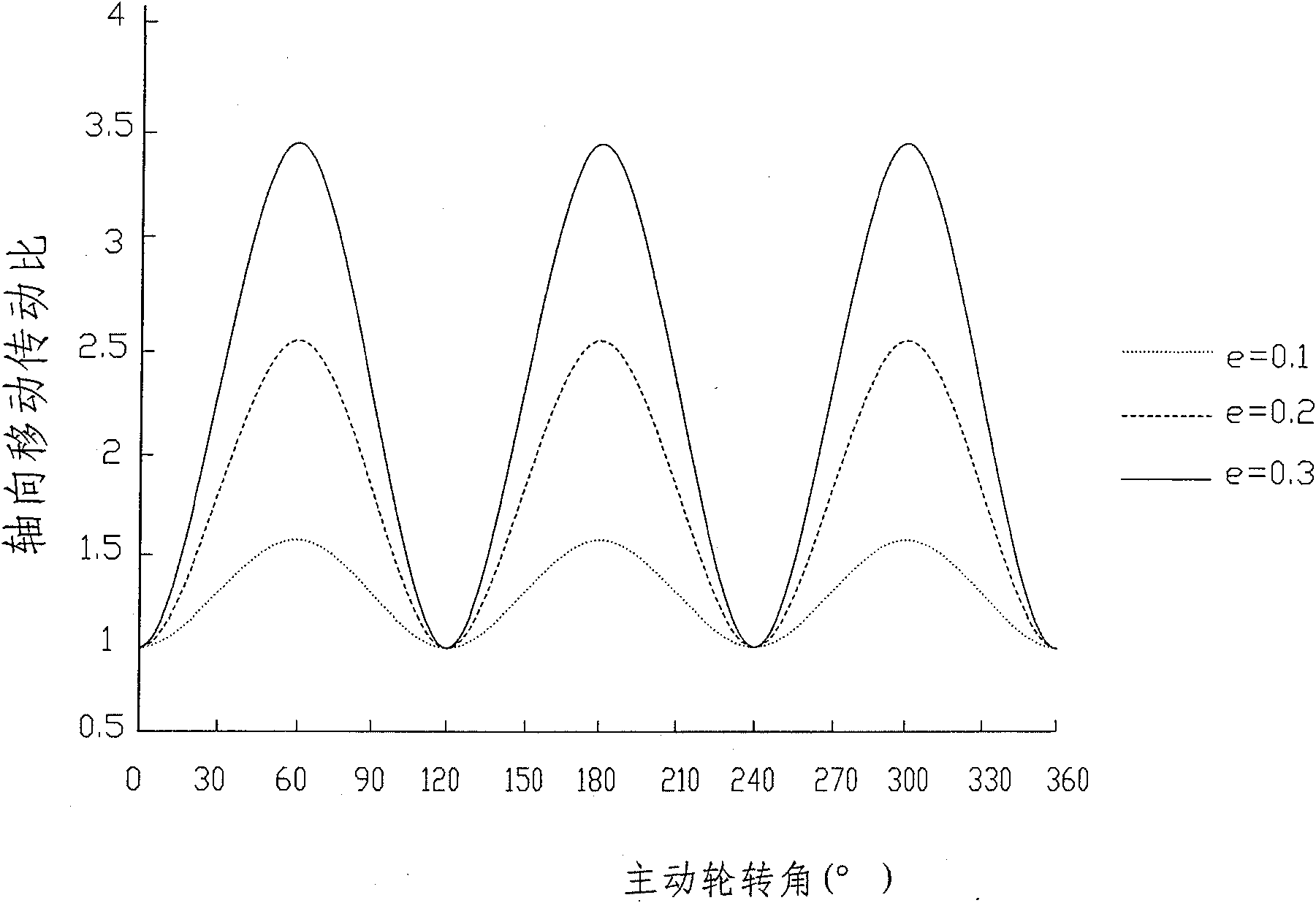

The invention discloses a trefoil bevel gear pair, which comprises a driving bevel gear and a driven bevel gear which mesh with each other, wherein the driving bevel gear and the driven bevel gear are in a trefoil structure. The trefoil bevel gears mesh each other, and can realize nonuniform speed ratio transmission of the concurrent axes and three periodic changes of the transmission ratio; according to different spherical section curvilinear equations of the trefoil bevel gears, the invention can realize fixed axis transmission, compound transmission of rotation and axial movement, and three continuous periodic changes; and therefore, the invention solves the problem of three periodic changes of the transmission ratio, can realize the fixed axis transmission, the compound movement of rotation and axial reciprocating movement, and can be suitable for nonuniform speed ratio transmission of concurrent axes as well as the special conditions of applications of movement and power transmission.

Description

technical field The invention relates to a non-circular gear transmission pair, in particular to a three-lobed bevel gear pair transmission mechanism. Background technique Gear transmission is a mechanical transmission that uses the teeth of two gears to mesh with each other to transmit power and motion. According to the relative position of the gear axis, it can be divided into parallel shaft cylindrical gear transmission, intersecting shaft bevel gear transmission and cross shaft helical gear transmission. Gear transmission has the characteristics of stability, precise transmission ratio, reliable operation, high efficiency, long life, and wide range of power, speed and size. Therefore, among all mechanical transmissions, gear transmission is the most widely used and can be used to transmit any two shafts. Between movement and power. In the meshing transmission of gear pairs, fixed ratio transmission is a widely used form. For example, cylindrical gears realize transmis...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F16H1/14F16H55/08

Inventor 林超侯玉杰俞松松

Owner CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com