High-order elliptic bevel gear pair with variable transmission ratios

A variable transmission ratio, elliptical cone technology, applied in the direction of transmission, gear transmission, belt/chain/gear, etc., can solve the problems of not having the general characteristics of other periodic variable ratio transmission, difficult processing, complicated design, etc., to achieve structural The effect of compactness, high transmission efficiency and large carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

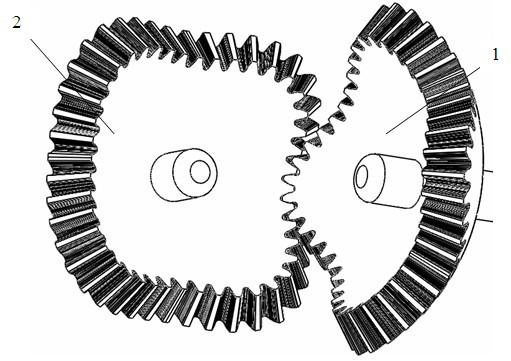

[0032] figure 1 It is the matching diagram of the high-order elliptical bevel gear pair with variable transmission ratio (take the 4th order as an example), as shown in the figure: the high-order elliptical bevel gear pair with variable transmission ratio in this embodiment includes the active elliptical bevel gear 1 and the secondary bevel gear pair that mesh with each other. Driven elliptical bevel gear 2, the active elliptical bevel gear 1 is a high-order elliptical bevel gear, and the driven elliptical bevel gear 2 is a high-order elliptical bevel gear that meshes with the active elliptical bevel gear and has the same order;

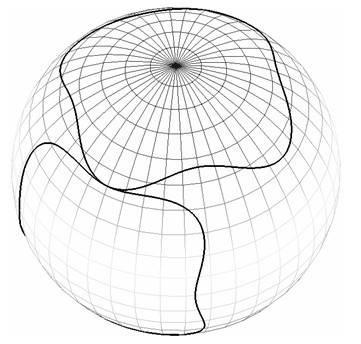

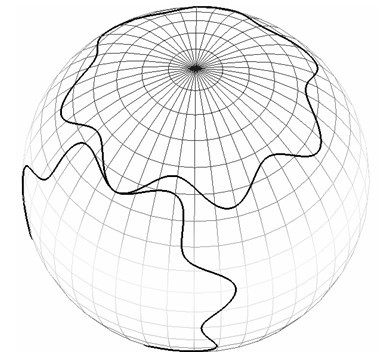

[0033] In this embodiment, the sub-cone equation of the active elliptical bevel gear is:

[0034]

[0035] The achieved transmission ratio is:

[0036]

[0037] in: ( ) is the eccentricity of the elliptical bevel gear, ( n ≥2) is the order of the elliptical bevel gear; is the rotation angle of the active elliptical bevel gear; that i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com