Contact locking device of single-breakpoint molded-case low-voltage circuit breaker

A low-voltage circuit breaker and locking device technology, applied to circuit breaker contacts, circuit breaker parts, etc., can solve the problems of easy wear and tear of the special shape of the moving contact, inability to lock reliably, and inconvenient assembly, so as to avoid arc re-ignition. , The effect of reliable action and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

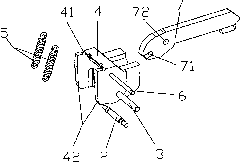

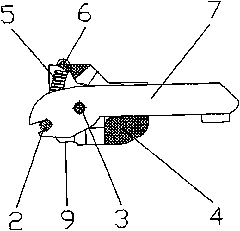

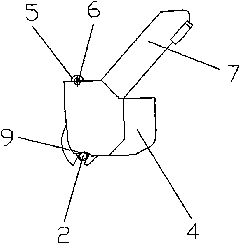

[0010] Such as figure 1 Show: the present invention is made up of shaft 2, mandrel 3, rotating shaft 4, extension spring 5, another shaft 6 and moving contact 7. A hole 72 is set at the rotating end of the moving contact 7, a groove 71 is set at the rotating top, the rotating shaft 4 is a structure with a cavity, the rotating end of the moving contact 7 is installed in the cavity of the rotating shaft 4, and the moving contact The free end of the head 7 is located outside the cavity of the rotating shaft 4, the mandrel 3 passes through the hole 72 on the movable contact 7, and its two ends are connected to the rotating shaft 4, specifically assembled in the grooves on the two side walls of the rotating shaft 4 cavity , so that the movable contact 7 is connected with the rotating shaft 4, and the movable contact 7 can rotate around the spindle 3 in the rotating shaft 4 as the center of rotation. The shaft 2 is located laterally in front of the outer contour surfaces 42 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com