Fluid flow valve

A fluid outlet and housing technology, applied in the field of fluid flow valves, can solve the problem of not being able to continuously release a small amount of air, and achieve the effects of cheap manufacturing, compact size and comprehensive design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

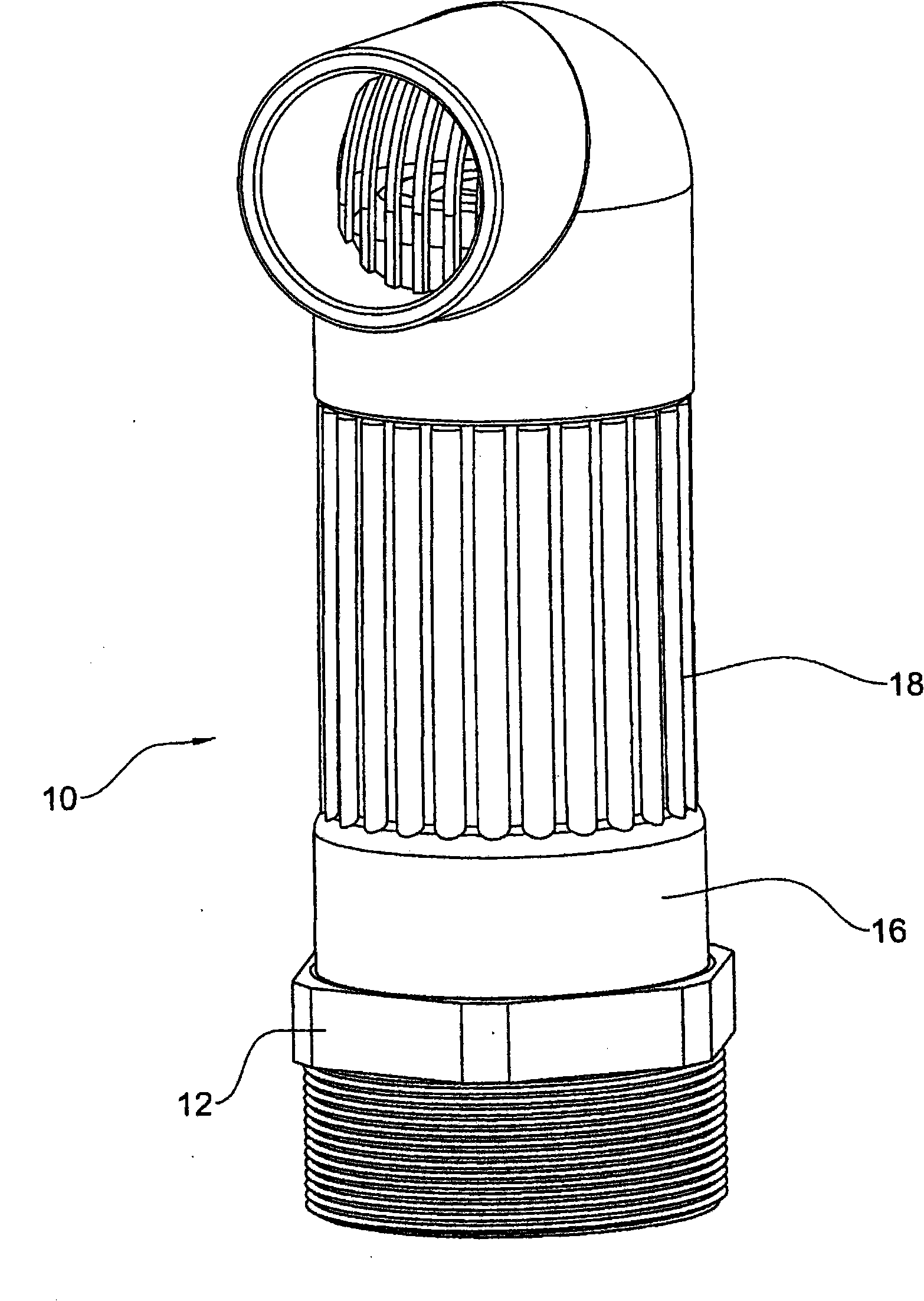

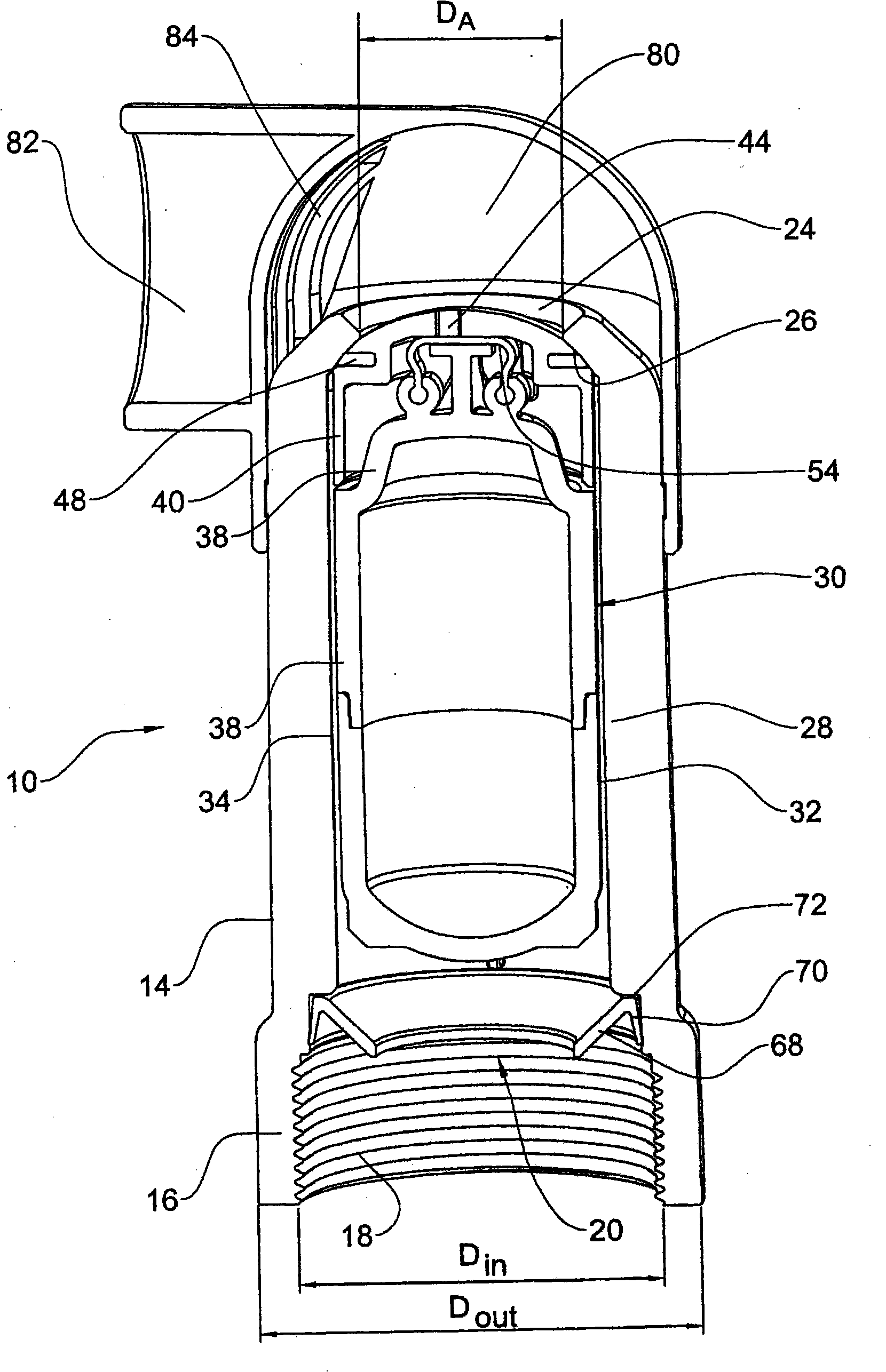

[0051] Note first the attached figure 1 and figure 2 , figure 1 and figure 2 A purge valve, referenced 10, according to the invention is shown. It should be noted that, figure 1 The valve assembly in figure 2 The threaded coupling 12 is not shown, which will be described in further detail below.

[0052] The valve 10 comprises a generally cylindrical housing 14 formed with a coupling portion 16 which in the present embodiment is an internal thread at 18 and also formed with a fluid inlet 20 and a fluid outlet 24 formed with a dynamic valve seat 26 at its bottom surface.

[0053] There are a number of radially extending axial ribs 28, two of which are figure 2 As can be seen in , the purpose is to limit the movement of the seal assembly 30 so that the seal assembly 30 moves axially but prevents it from rotating.

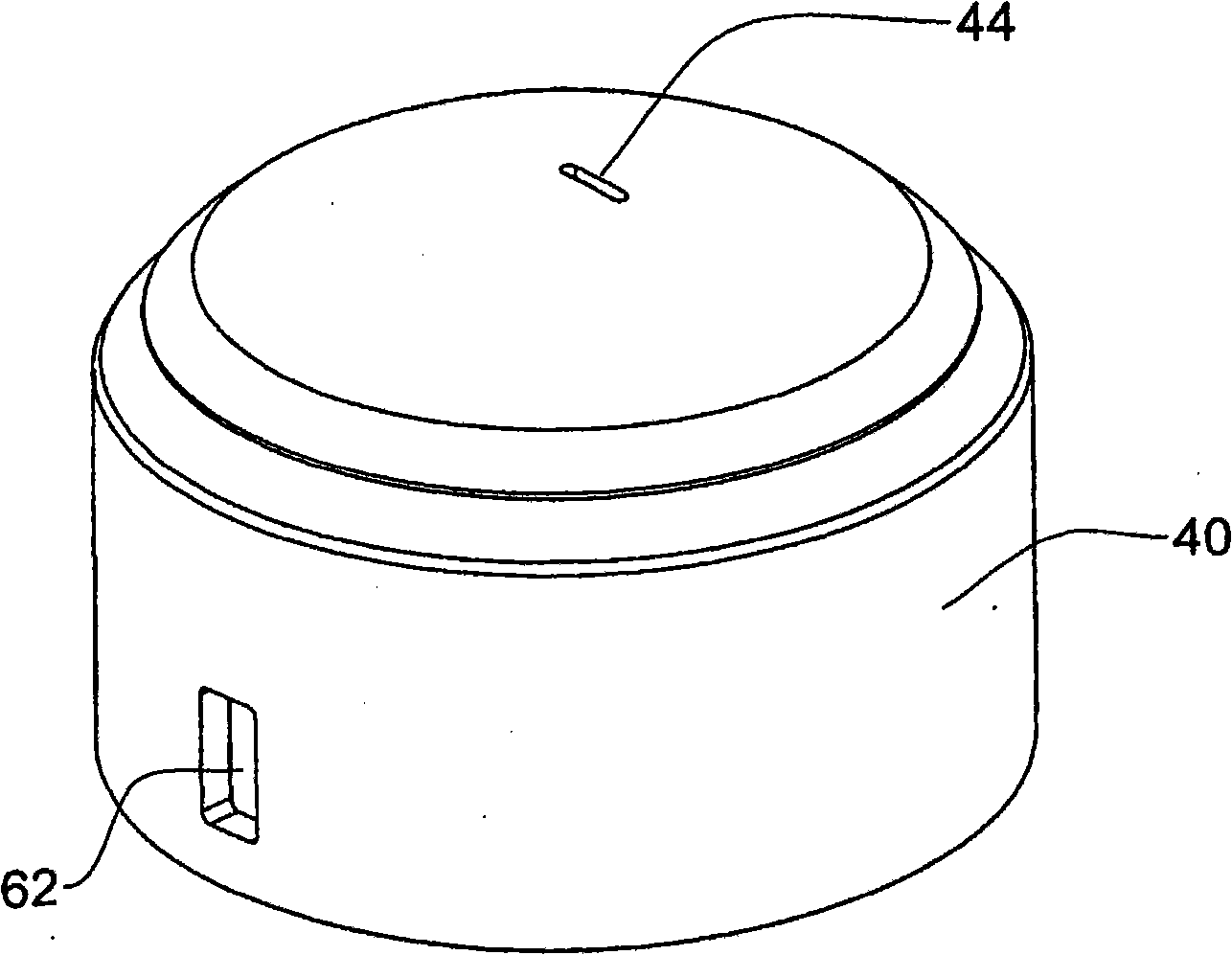

[0054] Seal assembly 30 includes a float member 32 including a cylindrical bottom 34 that is sealed by a float closure member 38, thereby collectively def...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com