Preparation method of potential test electrolyte tank

An electrolytic cell and potential technology, applied in the direction of electrochemical variables of materials, can solve problems such as being unsuitable for finished product detection, and achieve the effect of small error in detection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

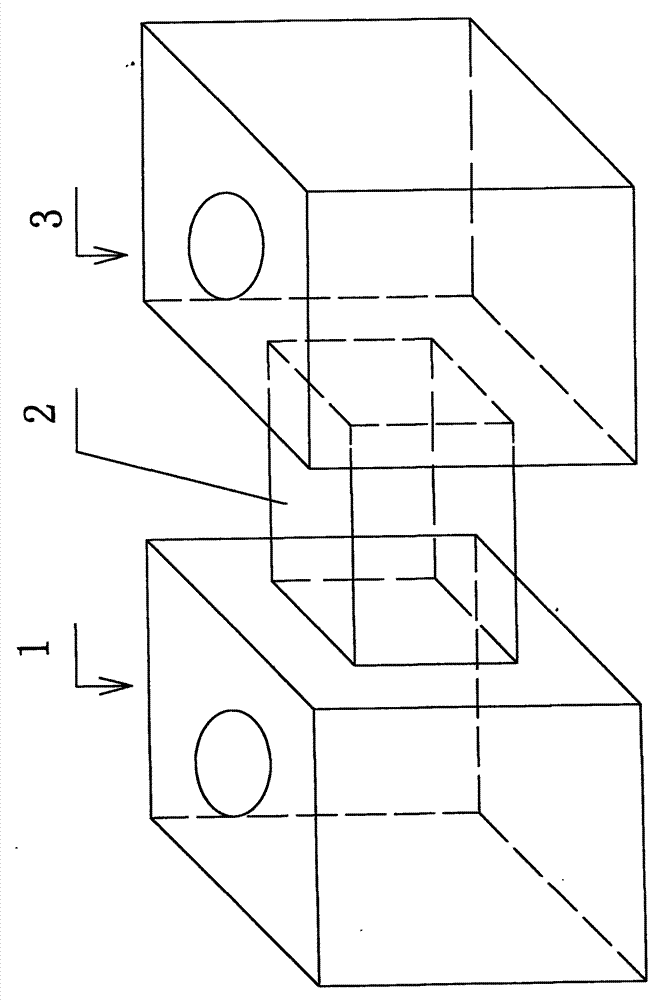

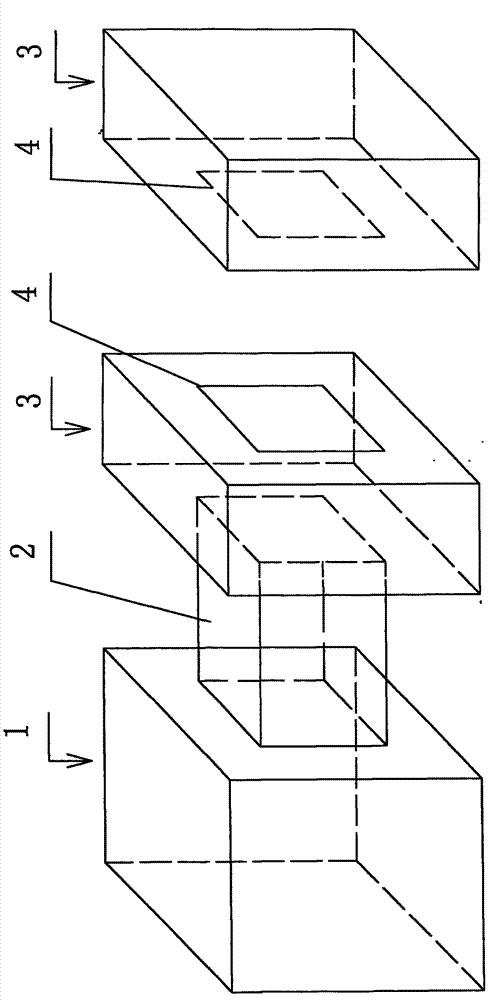

[0015] see figure 2 , figure 2 It is a structural schematic diagram of an electrode network potential test electrolyzer involved in the present invention. Depend on figure 2 It can be seen that the preparation method of the potential test electrolytic cell of the present invention includes the following process: the anode end 3 that is put into the anode test piece is divided into two by the middle, and becomes two separate anode ends. The separation of the two separated anode ends is aligned with the position of the channel 2, and the opening size is 20mm×20mm, and a soft rubber plate 4 for sealing is pasted around the opening.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com