Flaw detector for wire rope

A flaw detection device and steel wire rope technology, which is applied in the direction of material magnetic variables, etc., can solve the problem that steel wire rope flaw detection takes a lot of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

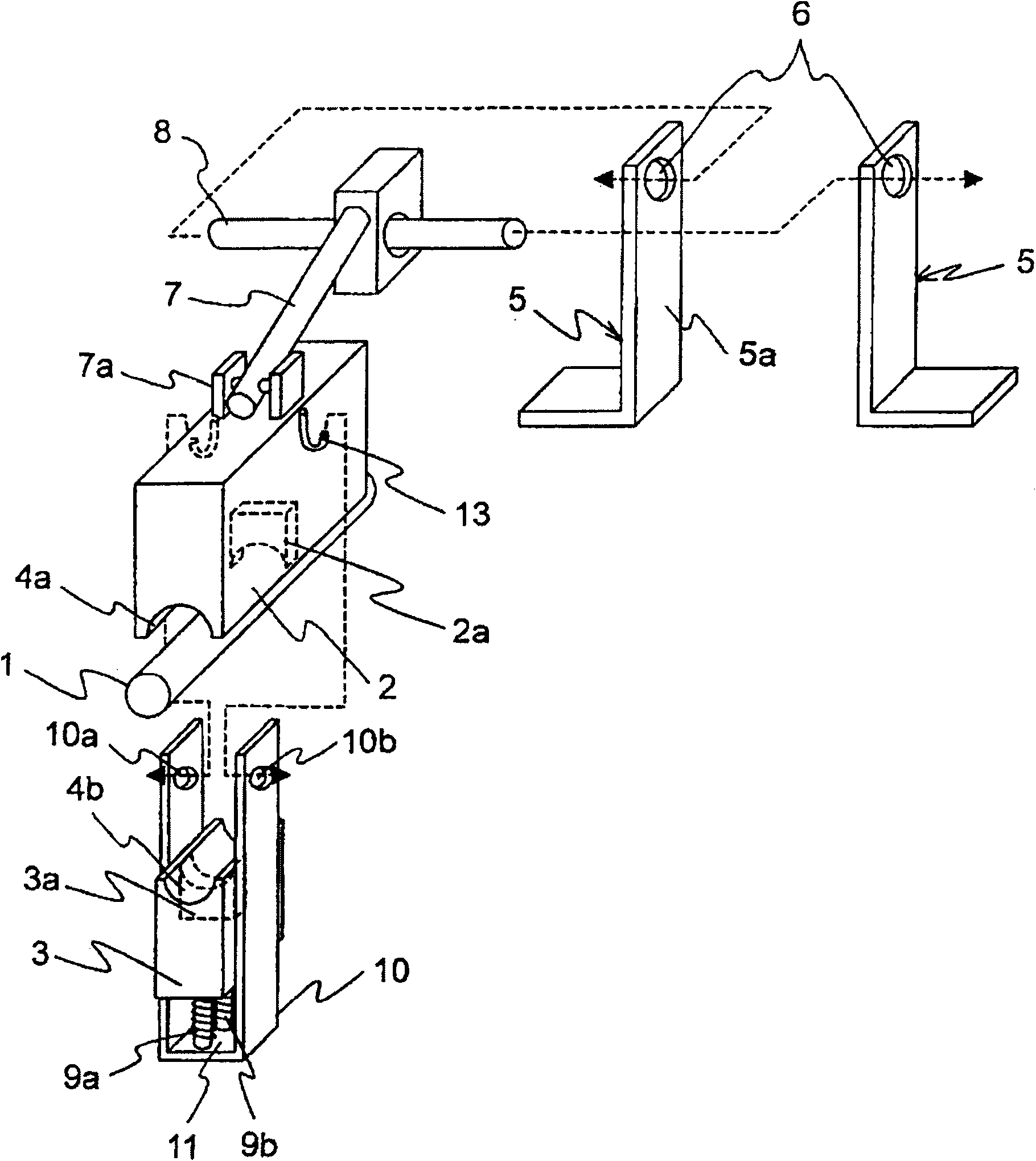

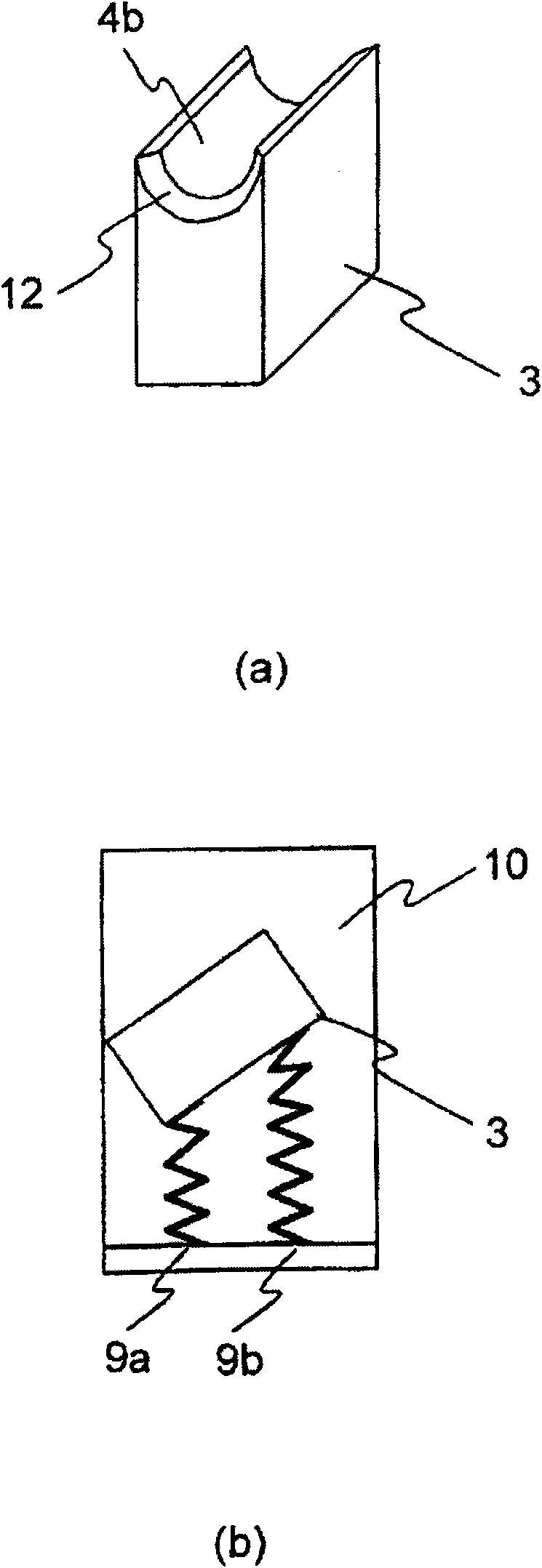

[0034] figure 1 It is an exploded perspective view showing the structure of the first embodiment of the flaw detection device for a steel wire rope according to the present invention. figure 2 is enlarged figure 1 Figure (a) is a perspective view showing the shape of the sensor base with the elastic body on the lower surface, and figure (b) shows the installation of the sensor base with the elastic body on the installation base. A side view of the state of the seat.

[0035] like figure 1 As shown, the first embodiment of the flaw detection device of the steel wire rope of the present invention is suitable for a machine such as an elevator with a steel wire rope 1, and is equipped with: a magnetization mechanism (not shown) that magnetizes the steel wire rope 1 along the length direction; The portion of the wire rope 1 magnetized by the magnetization mechanism includes sensor bases 2 and 3 of the magnetic sensors 2 a and 3 a that detect leakage magnetic flux leaked from a ...

Embodiment approach

[0052] In addition, in the first embodiment of the present invention, the rotating rods 8 are respectively inserted into the through holes 6a of the jig 5 mounted on the external non-working part, and the sensor base 2 as a whole can rotate around the position of the rotating rod 8 with respect to the jig 5 . Since the axis rotates, when a strong impact is received by the above-mentioned strands, the entire sensor base 2 rotates relative to the jig 5 . Therefore, the device can be prevented from malfunctioning due to the impact, and the durability of the device can be improved.

[0053] In addition, in the first embodiment of the present invention, the above-mentioned strands smoothly enter the guide of the sensor base 3 by utilizing the notch portion 12 formed on the side where the wire rope 1 enters in both ends of the guide surface 4b of the sensor base 3. Therefore, the impact generated when the above-mentioned strands enter the sensor base 3 can be reduced, and the load a...

no. 2 approach

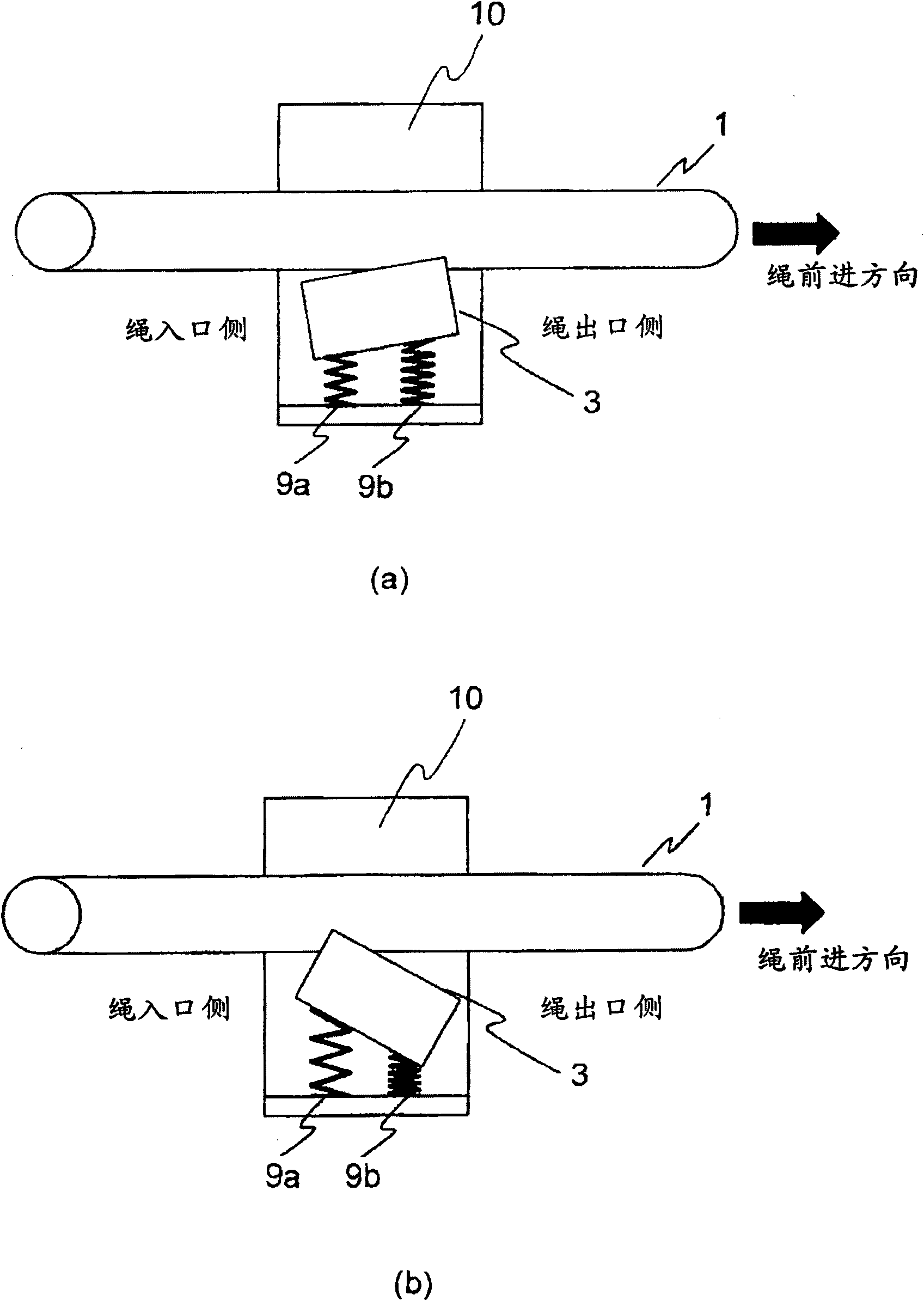

[0056] Figure 4 It is a side view showing the state where the sensor base having an elastic body included in the second embodiment of the flaw detection device for a steel wire rope according to the present invention is mounted on the mounting base.

[0057] like Figure 4 As shown, the difference between the second embodiment of the present invention and the first embodiment of the present invention is that the outlet side of the steel wire rope 1 of the sensor base 3 at both ends of the guide surface 4b is rotatably formed by an elastic body such as a spring 9c , the other structures are the same as those of the first embodiment.

[0058] According to the second embodiment of the present invention constituted in this way, the same effects as those of the above-mentioned first embodiment of the present invention can be obtained. In addition, since the spring 9c is located at both ends of the guide surface 4b of the sensor base 3, the wire rope 1 Therefore, during the above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com