Flaw detecting device for pipeline inner wall detection

A flaw detection device and pipeline technology, applied in special pipes, pipe components, pipes/pipe joints/pipe fittings, etc., can solve the problems of poor pipeline detection effect, high price, poor detection effect, etc., and achieve easy promotion, low price, and structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

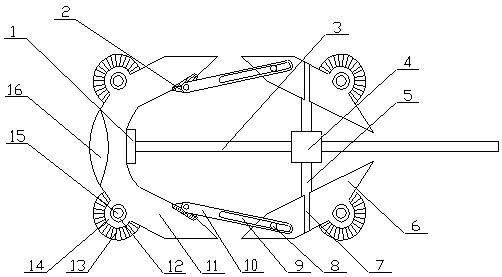

[0024]A pipeline inner wall inspection and flaw detection device of the present invention is realized in this way. It consists of a main device and an adjustment device. The main device consists of a central bearing (1), a support arm (11), a connecting bearing (12), a support wheel (13), It is composed of a fixed frame (14), a connecting shaft (15) and a detection shield (16). The support arm (11) is an arc-shaped plate structure, and a slot is opened at the front end of the middle part of the support arm (11). There is a detection shield (16) on the outside of the placement groove, the center bearing (1) supports the middle part of the inner side of the arm (11) and communicates with the placement groove, and the two ends of the support arm (11) are respectively connected to the The centerlines of the central bearings (1) are parallel to each other, magnet strips are placed on both ends of the support arm (11), and two fixed frames (14) are symmetrically placed on the outer e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com