3D weld detection integrated intelligent welding system

A weld detection and welding system technology, applied in the direction of welding accessories, welding rod characteristics, electrode support devices, etc., can solve the problems that affect the detection accuracy of flaw detection equipment and reduce welding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

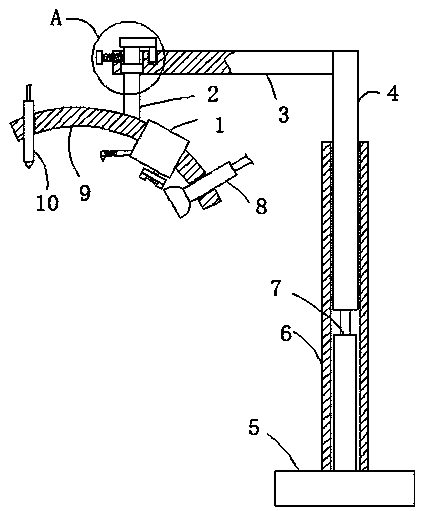

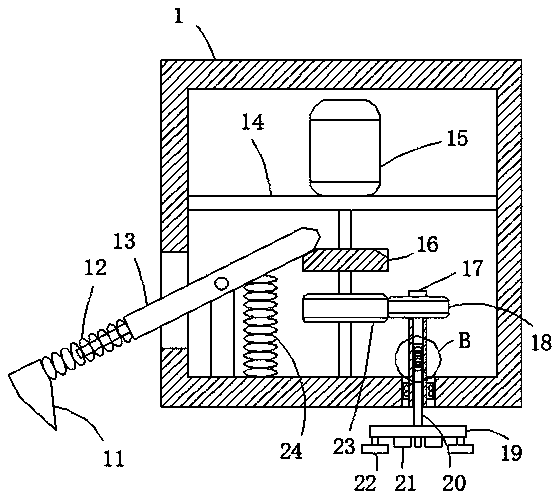

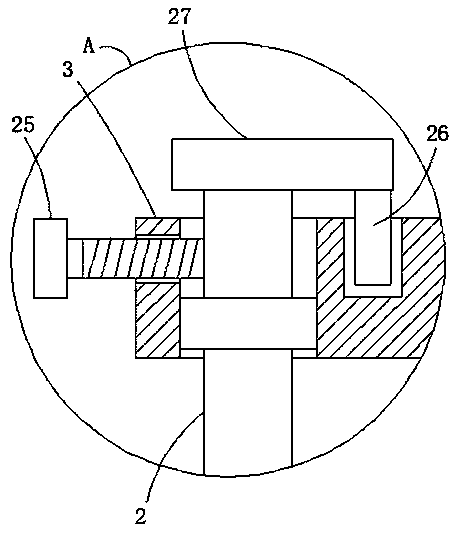

[0025] 3D weld detection integrated intelligent welding system, including mounting base 5, arc-shaped plate 9, intelligent welding machine welding gun head 10 and weld seam detection probe 8 arranged on arc-shaped plate 9, the upper end of arc-shaped plate 9 is vertical A connecting rod 2 is fixedly connected, one side of the arc-shaped plate 9 is fixedly connected with a housing 1 through a mounting hole, a cleaning mechanism is connected inside the housing 1, and a rectangular tube 6 is fixedly connected to the center of the upper end of the mounting seat 5, and the rectangular tube 6 There is an electric push rod 7 inside, one end of the electric push rod 7 is fixedly connected to the upper end of the mounting base 5, the other end of the electric push rod 7 is fixedly connected to a rectangular rod 4, and the upper end of the rectangular rod 4 extends to the outside of the rectangular tube 6 and is fixed A cross bar 3 is connected, and the right end of the cross bar 3 is ro...

Embodiment 2

[0027] Embodiment 2: the difference based on Embodiment 1 is;

[0028]The cleaning mechanism includes a fixed rod fixed in the housing 1. The upper end of the fixed rod is connected with an inclined transmission rod 13 through a rotating shaft. The lower side of the housing 1 is provided with a rectangular opening through which one end of the transmission rod 13 passes. The rectangular opening is fixedly connected with the first spring 12, the end of the first spring 12 away from the transmission rod 13 is fixedly connected with the conical block 11, the first spring 12 is movably sleeved with a support rod, and one end of the support rod passes through the first spring 12 And fixedly connected with one end of the transmission rod 13, the rod wall of the transmission rod 13 is fixedly connected with a tension spring 24, the lower end of the tension spring 24 is fixedly connected with the lower end inner wall of the housing 1, and the horizontal plate 14 is fixedly connected in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com