Method and device for simulating strata pressure in three-dimensional simulation test for producing oil by injecting multicomponent thermal fluid

A multi-component thermal fluid and simulation test technology, which is applied in the field of formation pressure simulation and device for three-dimensional simulation test of multi-component thermal fluid injection, can solve the problem of inflexible pressure control methods, frequent actions of hydraulic pumps entering and exiting pumps, and low pressure control accuracy To achieve the effect of improving stability and safety, preventing channeling of displacement medium, and avoiding complex thermal insulation structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

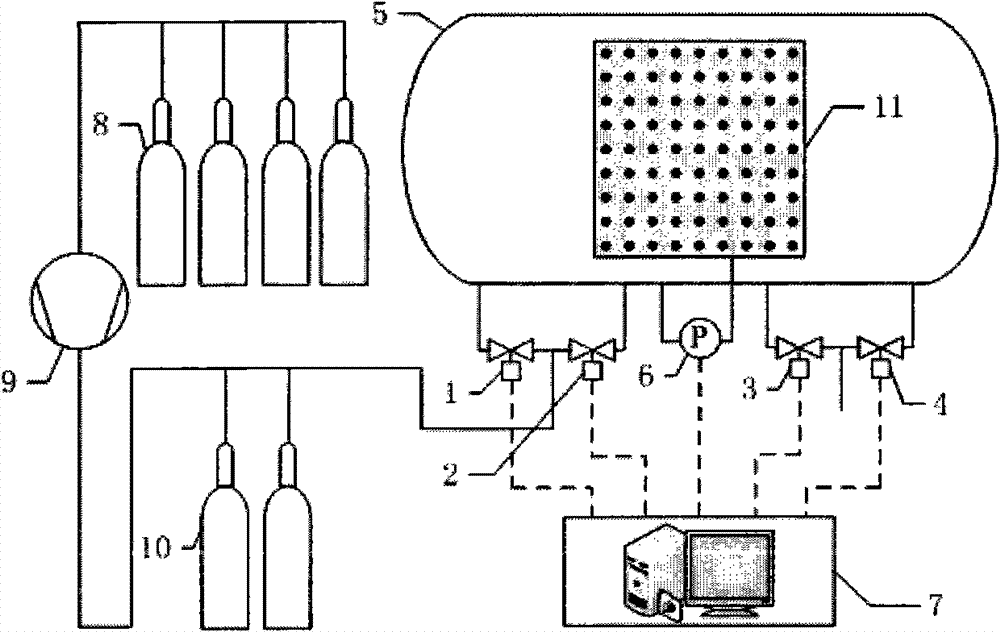

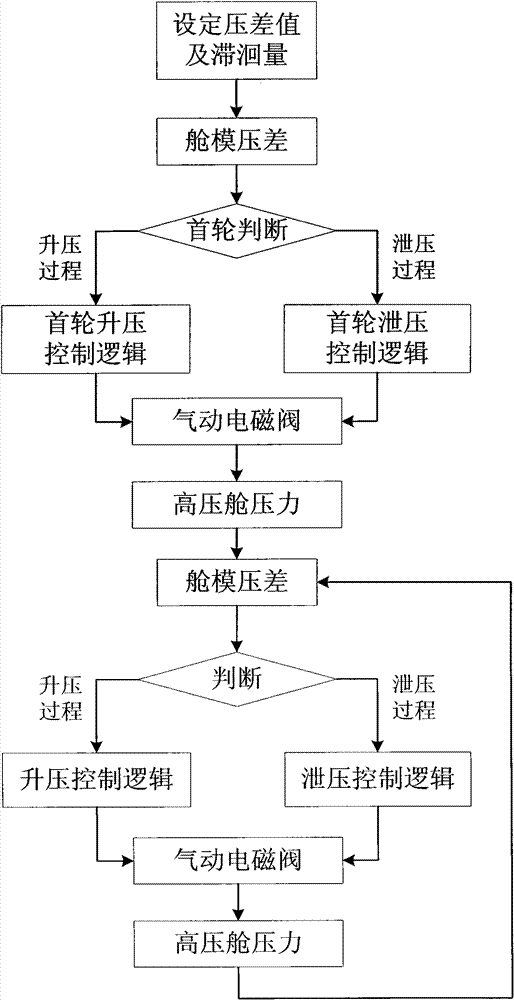

Embodiment 1

[0073] 1. Setting of pressure difference and hysteresis: the test operating pressure is 2MPa, the model body 11 is a thin-walled model with a wall thickness of 0.5mm, and the pressure bearing capacity is 50-80KPa, so the pressure difference setting value between hyperbaric chamber 5 and model body 11 is 50KPa; the hysteresis volume is set to 12KPa according to the test pressure;

[0074] 2. The program detects that the initial cabin mold pressure difference is 45KPa, and within the range of 10-84KPa (50+2×12+10KPa), the valve remains closed when there is no action.

[0075] 3. The first round control process of saturated oil

[0076] The pressure of the model body 11 keeps rising during the pressurized saturated oil test

[0077] 3.1 The pressure difference of the cabin model is continuously decreasing. When the pressure difference of the cabin model is lower than 10KPa, it is judged to be a boosting process;

[0078] 3.2 The intake valve 1 and intake valve 2 are both open, ...

Embodiment 2

[0095] 1. Setting of differential pressure and hysteresis: the test operating pressure is 8MPa, the model body 11 is a thin-walled model with a wall thickness of 0.5mm, and the pressure bearing capacity is 50-80KPa, so the pressure difference setting value between hyperbaric chamber 5 and model body 11 is 50KPa; the hysteresis volume is set to 8KPa according to the test pressure;

[0096] 2. The program detects that the initial cabin mold pressure difference is 45KPa, and within the range of 10-76KPa (50+2×8+10KPa), the valve remains closed when there is no action.

[0097] 3. The first round control process of saturated oil

[0098] The pressure of the model body 11 keeps rising during the pressurized saturated oil test

[0099] 3.1 The pressure difference of the cabin model is continuously decreasing. When the pressure difference of the cabin model is lower than 10KPa, it is judged to be a boosting process;

[0100] 3.2 The intake valve 1 and intake valve 2 are both open, ...

Embodiment 3

[0117] 1. Setting of pressure difference and hysteresis: the test operating pressure is 12MPa, the model body 11 is a thin-walled model with a wall thickness of 0.5mm, and the pressure bearing capacity is 50-80KPa, so the pressure difference setting value between hyperbaric chamber 5 and model body 11 is 50KPa; the hysteresis volume is set to 3KPa according to the test pressure;

[0118] 2. The program detects that the initial cabin mold pressure difference is 45KPa, and within the range of 10-66KPa (50+2×3K+10Pa), the valve remains closed even if it does not operate.

[0119] 3. The first round control process of saturated oil

[0120] The pressure of the model body 11 keeps rising during the pressurized saturated oil test

[0121] 3.1 The pressure difference of the cabin model is continuously decreasing. When the pressure difference of the cabin model is lower than 10KPa, it is judged to be a boosting process;

[0122] 3.2 The intake valve 1 and intake valve 2 are both ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com