Rubber vibration isolator

A rubber vibration isolator, rubber technology, applied to the vibration isolation of zero stiffness rubber vibration isolators. field, it can solve the problems of small chassis and hard disk drive space, high price, complicated settings, etc., and achieve the effect of low price, strong adaptability and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings, and the same or similar symbols in each figure represent the same or similar parts.

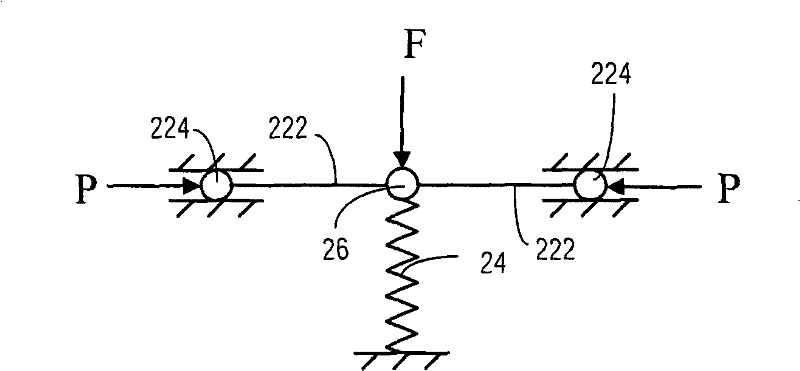

[0023] Combine now Figure 1a-1c Briefly explain the working principle of the rubber vibration isolator of the present invention.

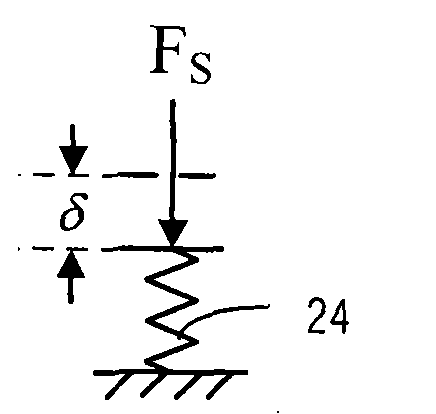

[0024] like Figure 1a As shown, an ordinary spring 24 is subjected to a downward pressure F S Under the action of , it is compressed δ, F S The ratio to δ is the positive stiffness coefficient K of the spring 24 S , the positive stiffness coefficient of the spring 24 is related to the material and shape of the spring.

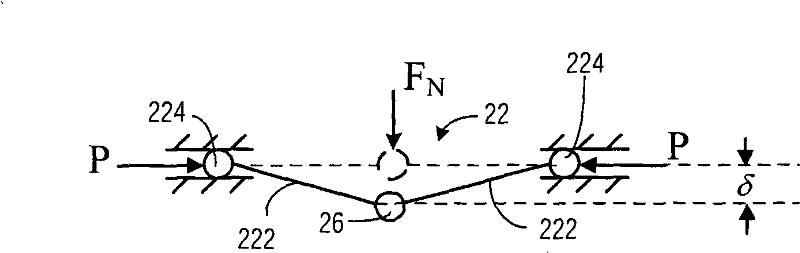

[0025] like Figure 1b Shown is a mechanism 22 for achieving negative stiffness having a long rod 222 with a hinge 26 in the center and a pivot 224 at each end of the rod 222 . For ease of descri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com