Lock type sealing electrical connector for curved groove

An electrical connector, curved groove technology, applied in the direction of connection, two-part connection device, parts of the connection device, etc., can solve problems such as sealing failure, and achieve the effect of preventing easy unlocking and facilitating locking operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

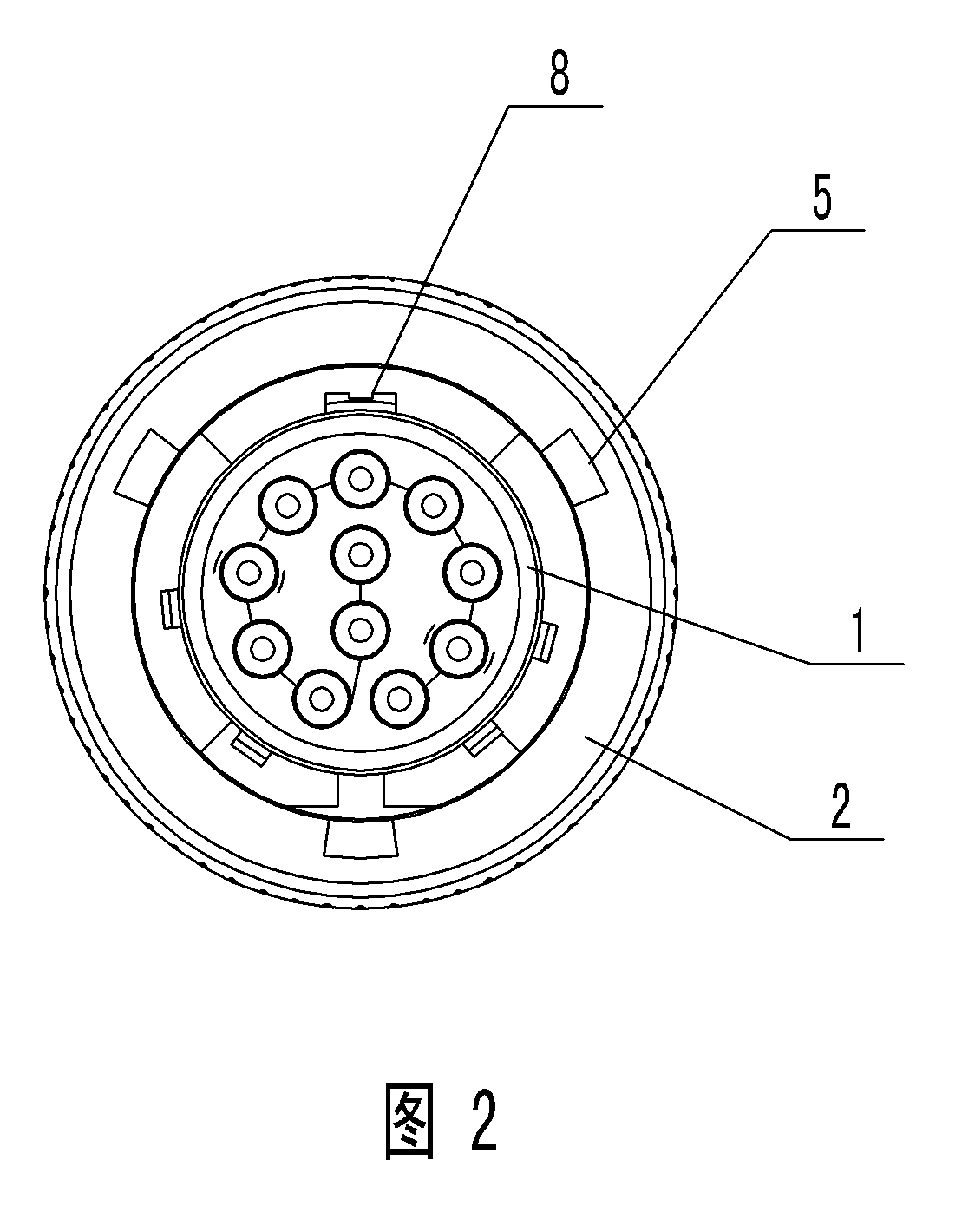

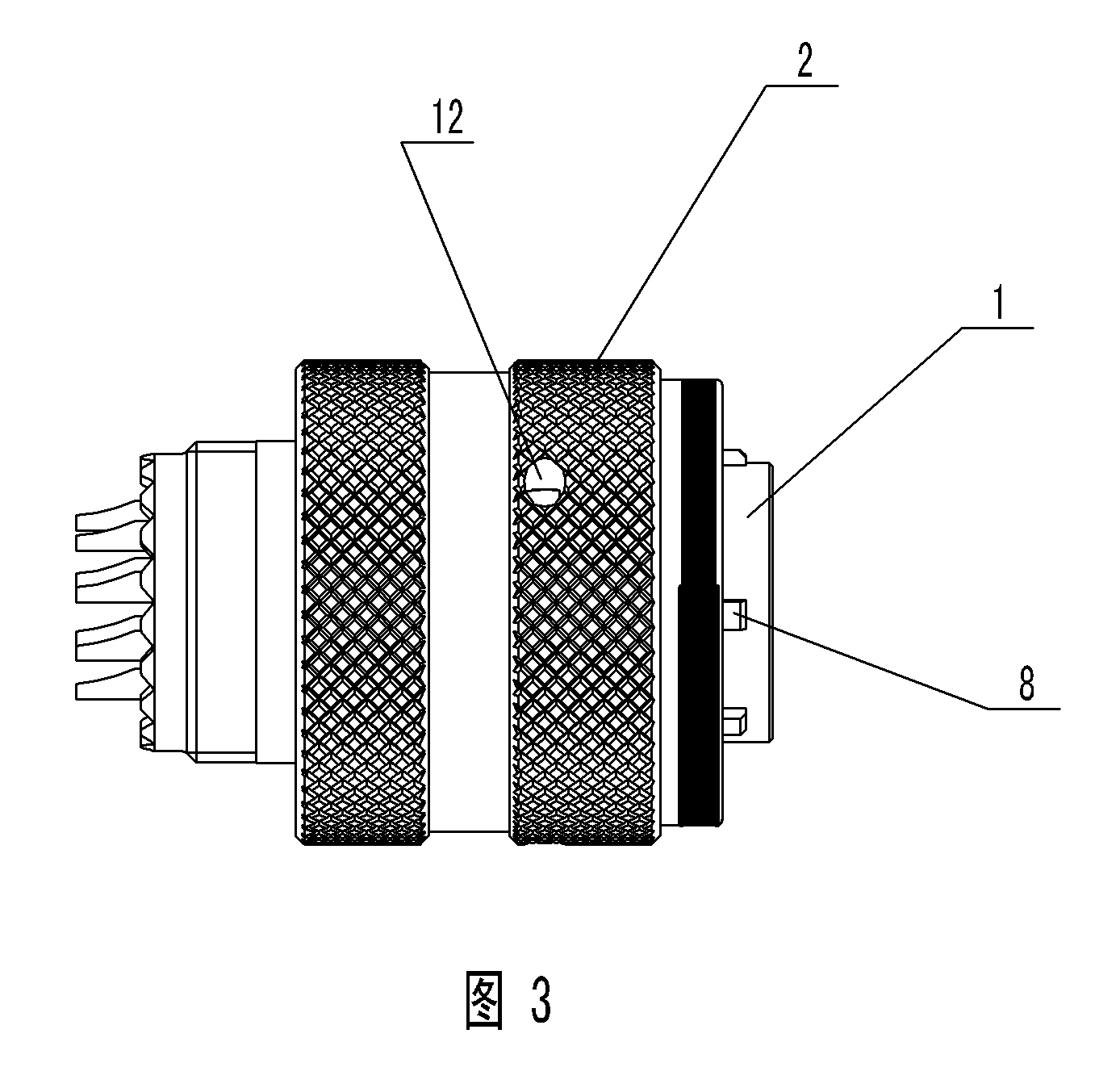

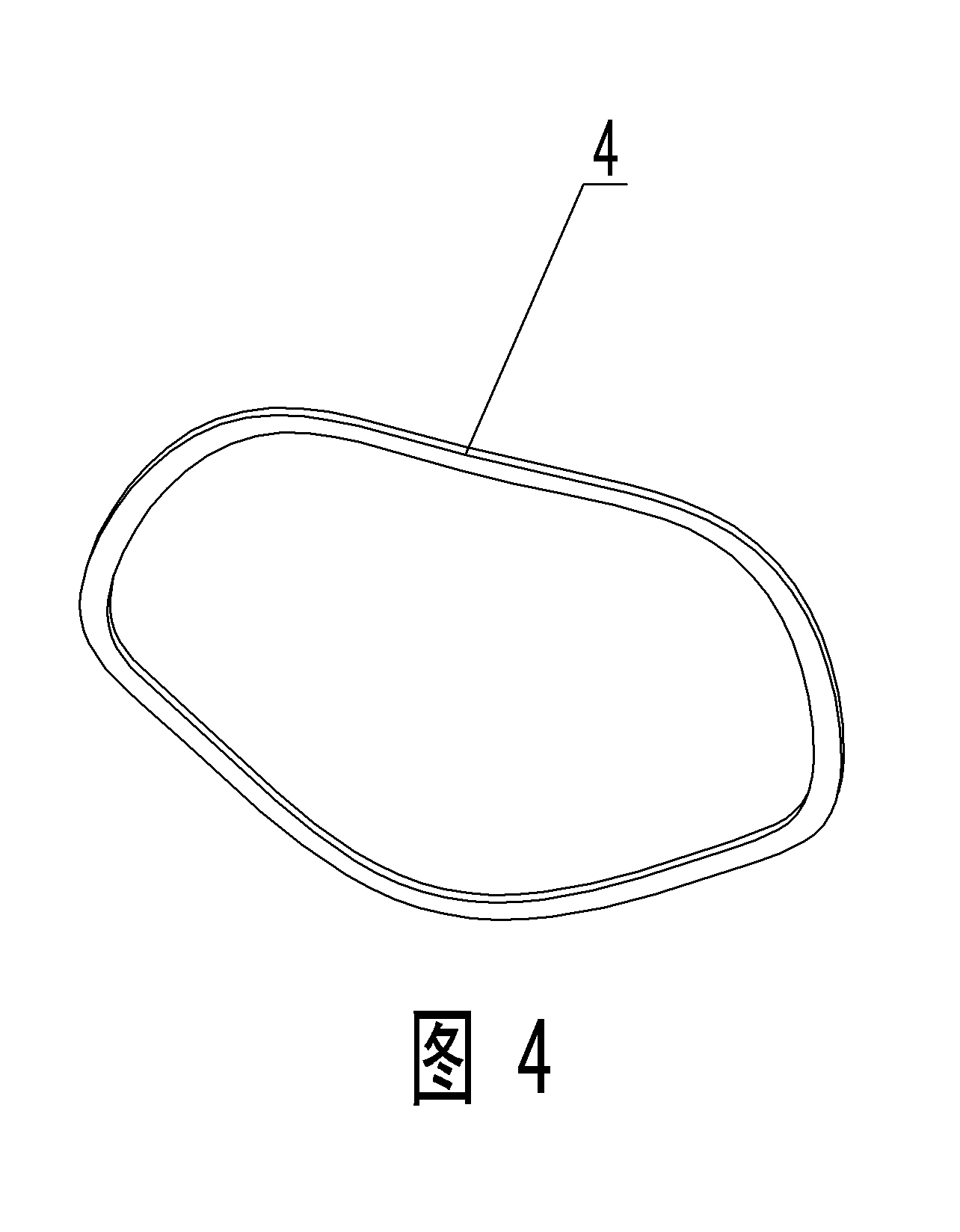

[0022] Such as Figure 1 to Figure 5 As shown, the plug 20 of the embodiment of the present invention is cylindrical as a whole, and the front and rear ends are the plug-in end and the terminal respectively. The plug includes a cylindrical plug housing 1 and a connecting cap set on the outer periphery of the plug housing 1 2. Both the plug housing 1 and the connecting cap 2 are made of metal. The plug housing 1 is equipped with a plug insulator 14 of insulating material. A plurality of guide keys 8 extending in the axial direction are provided on the outer peripheral surface near the front end of the plug housing 1, and three curved grooves 5 extending backward from the front end of the connecting cap are opened on the inner wall of the connecting cap 2, each On the inner wall of the connection cap 2 near the end of the curved groove 5, there is a staple hole 12 through the connection cap 2 for the staple on the socket housing to snap in. A color band 15 for identification is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com