Feeding machine and feeding uniformity testing method

A feeding machine and feed technology, which is applied in the testing, measuring devices, instruments, etc. of machine/structural components, can solve the problems of inaccurate test and troublesome feed collection, etc. Simple, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

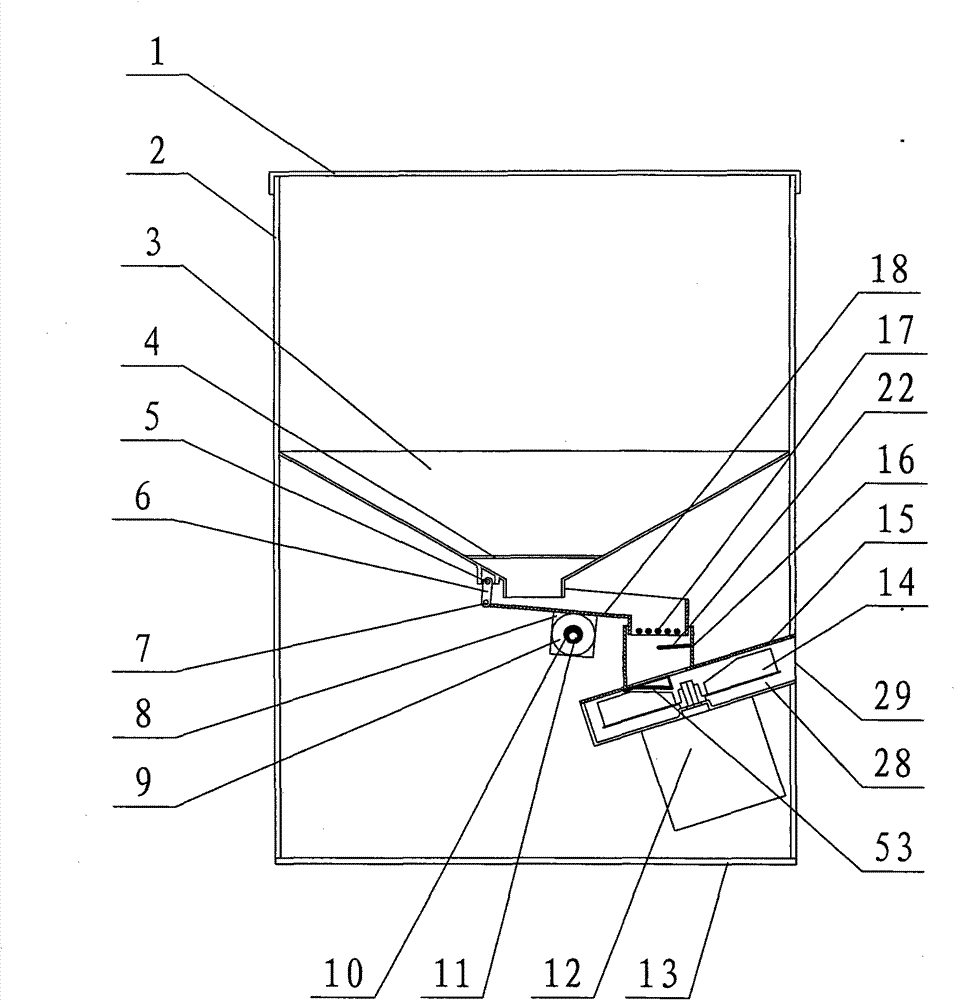

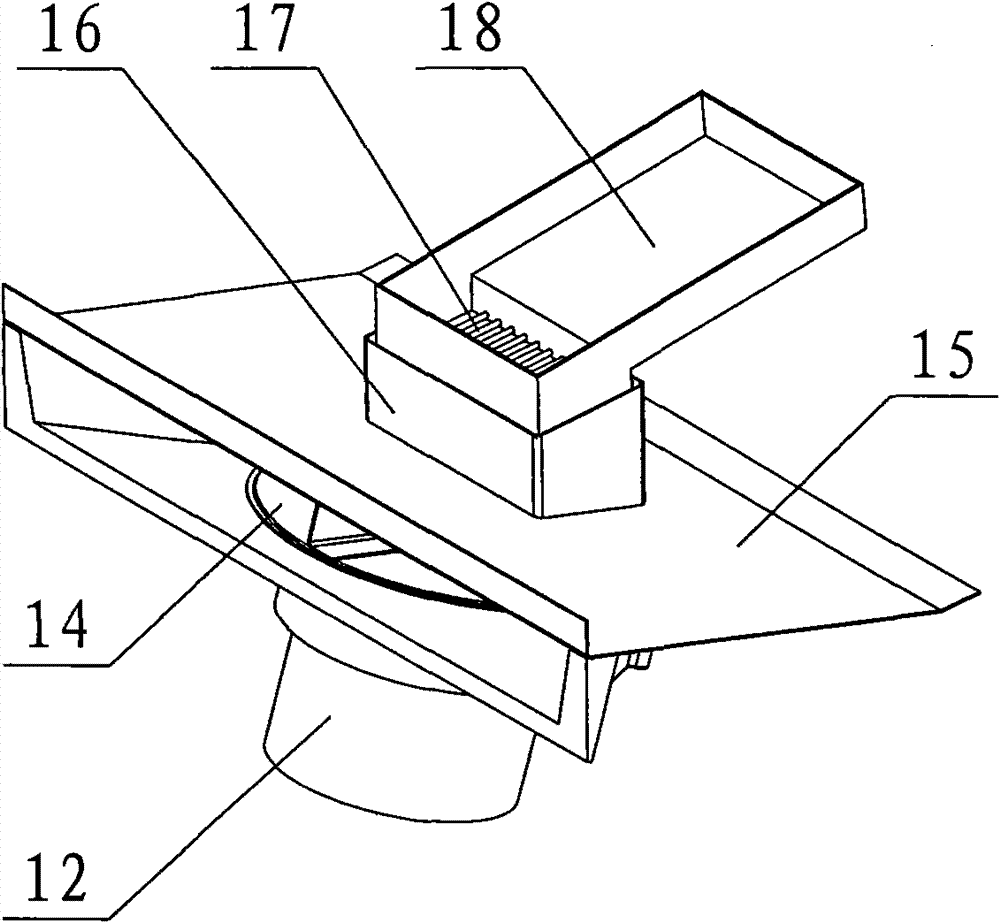

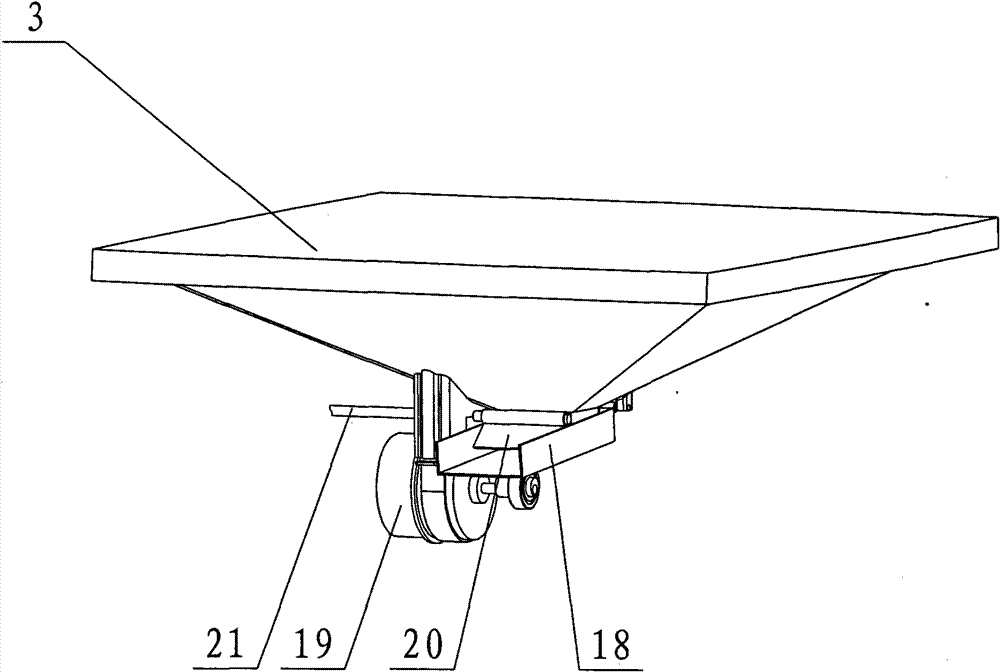

[0038] The present invention will be further described below with specific embodiment, see Figure 1-13 :

[0039] A feeding machine of the present invention is mainly composed of a cabinet 2, a controller 34, a feeding mechanism, a throwing mechanism, a hopper 3, a case cover 1, etc., and the throwing mechanism is mainly composed of a throwing chamber 28, a throwing motor 12, The throwing tray top plate 15, the throwing tray 14, etc., the throwing mechanism is installed obliquely on the lower part of the cabinet 2, the throwing port 29 is higher than the inside, and a feeding tray 53 is formed under the throwing tray top plate 15, and the feeding tray The three sides of 53 are connected to the top plate 15 of the throwing tray, and one side is opened as a feeding port. The feed sent by the feeding mechanism falls from the open side of the feeding tray 53 to the throwing tray 14 in rows, and the opposite position of the throwing tray 14 is It is fixed, and after adjusting the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com