a feeding machine

A feeding machine and chassis technology, applied in fish farming, application, animal husbandry, etc., can solve the problems of vibration sheet or elastic body fatigue fracture, failure to achieve control effect, operator trouble, etc., to achieve low cost, prevent The effect of stealing feed and biting wires, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

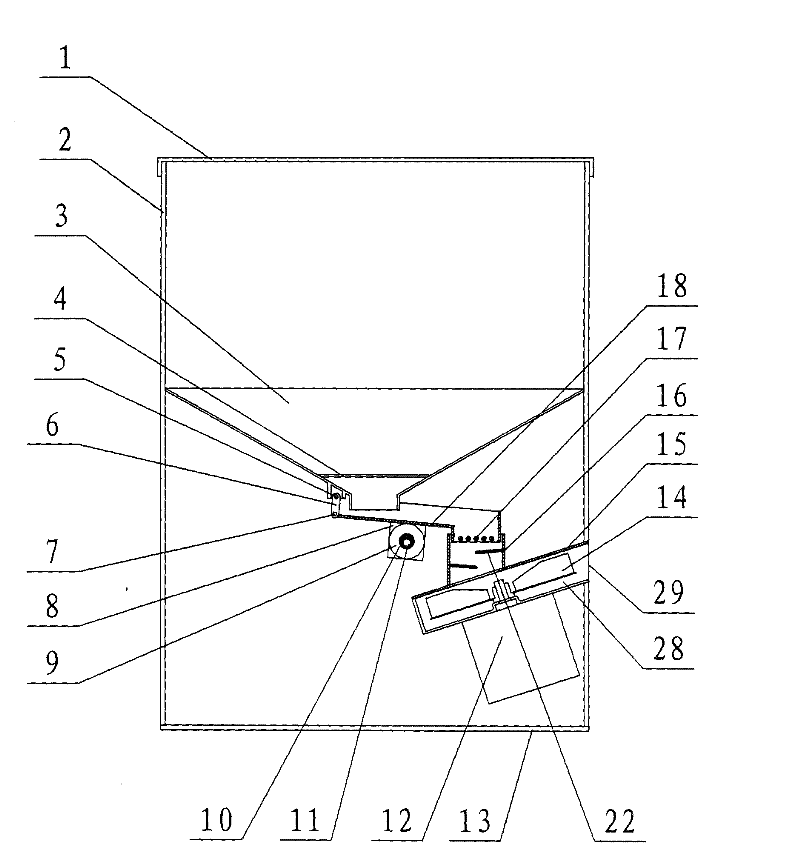

[0030] The present invention will be further described below with specific embodiment, see Figure 1-9 :

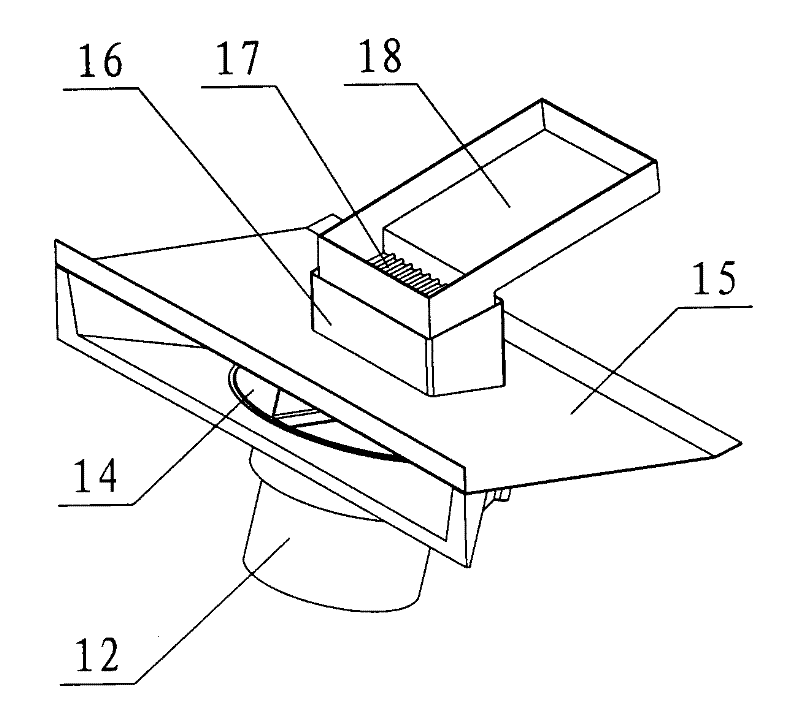

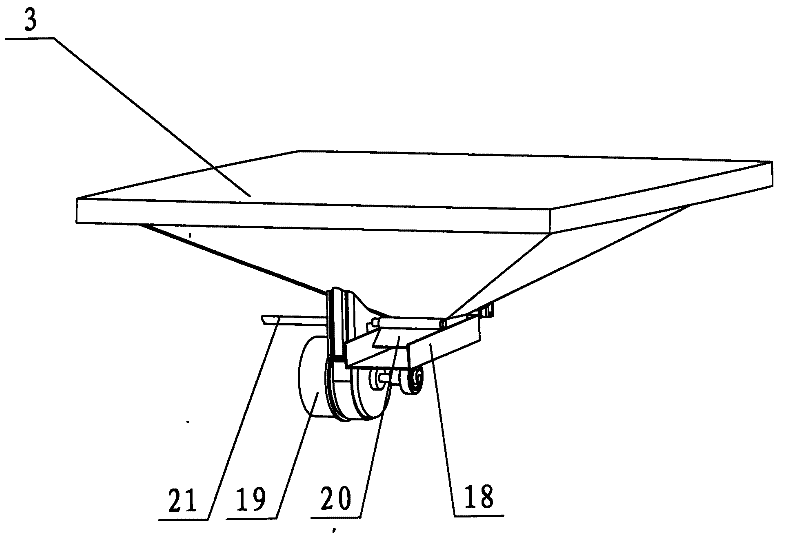

[0031] A feeding machine of the present invention is mainly composed of a casing 2, a control box 34, a feeding mechanism for throwing movement, a throwing motor 12, a throwing tray 14, a box cover 1, a box bottom plate 13, etc., the so-called throwing movement The feeding mechanism is: there is a lower shaft 7 at the non-feeding port end of the feeding chute 18, the lower shaft 7 is connected to the upper shaft 5 through the connecting rod 6, the upper shaft 5 is fixed under the hopper 3, and there is a bearing seat 8 under the feeding chute 18 , the bearing seat is divided into two halves, one half of which is integrated with the feeding trough, and there is a ball bearing 9 in the bearing seat 8, the ball bearing 9 is connected to the motor shaft 11 through the eccentric sleeve 10, and the motor shaft 11 supports the middle part of the feeding chute 18, the so-called ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com