Toilet appliance action part maintenance method

A technology for toilets and appliances, applied in the field of toilet appliances, can solve problems such as toilet hygiene problems, and achieve the effects of being conducive to popularization and application, saving manpower and improving hygiene level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

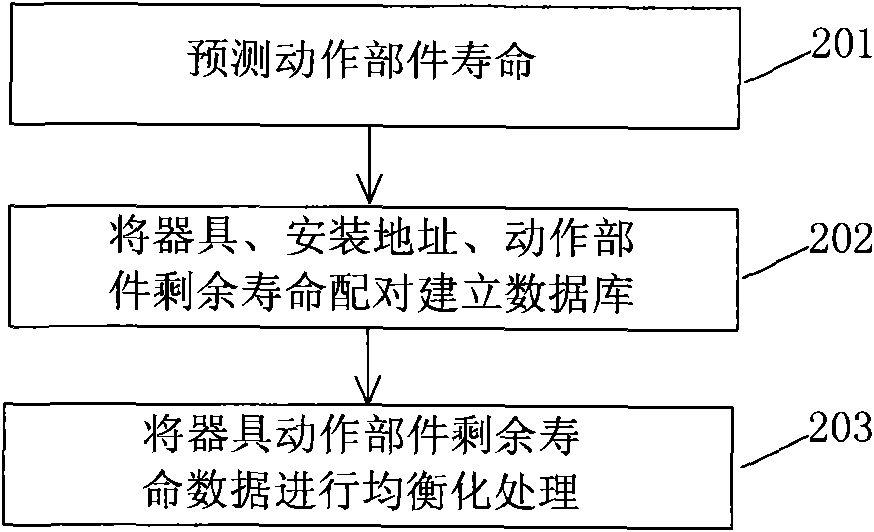

[0039] Embodiments of the present invention provide a maintenance method for toilet appliance action parts, see figure 2 , this embodiment includes the following steps:

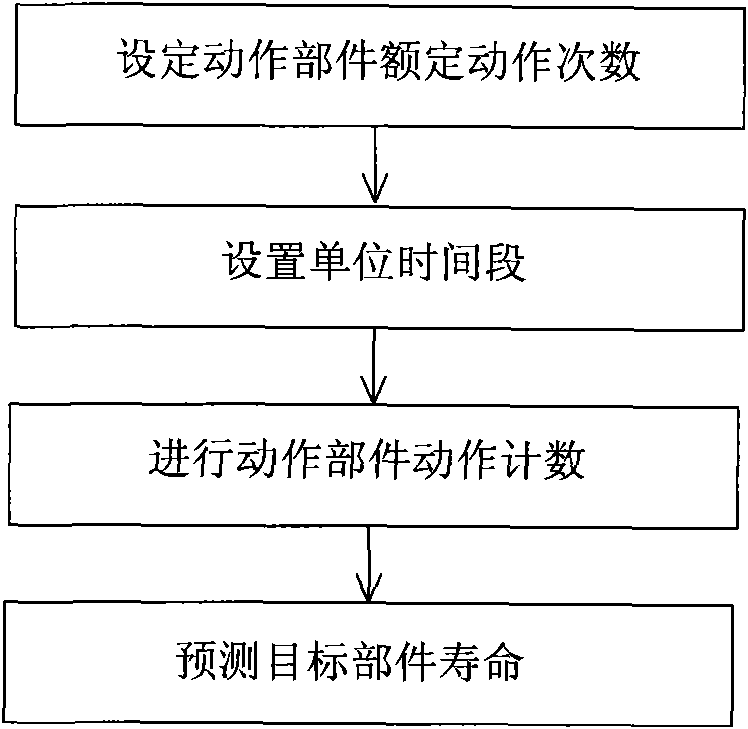

[0040] Step 201: Predict the remaining life of the moving parts. The data of the number of actions of the appliance is collected to predict the life of the action parts, that is, to predict the time when the action parts of the appliance may fail. The process of predicting the life of an appliance's operating parts involves the following steps, see image 3 ,

[0041] First set the rated number of actions of the moving parts; this parameter is provided by the manufacturer to describe the service life of the moving parts, for example, if the action is 300,000 times, then set 300,000 times as the rated number of actions of the moving parts.

[0042] Then set the unit time period, fo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap