Workpiece processing system and method

A technology for processing systems and workpieces, which is applied to electrical components, electrical components, rotary printing machines, etc., and can solve problems such as large footprints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

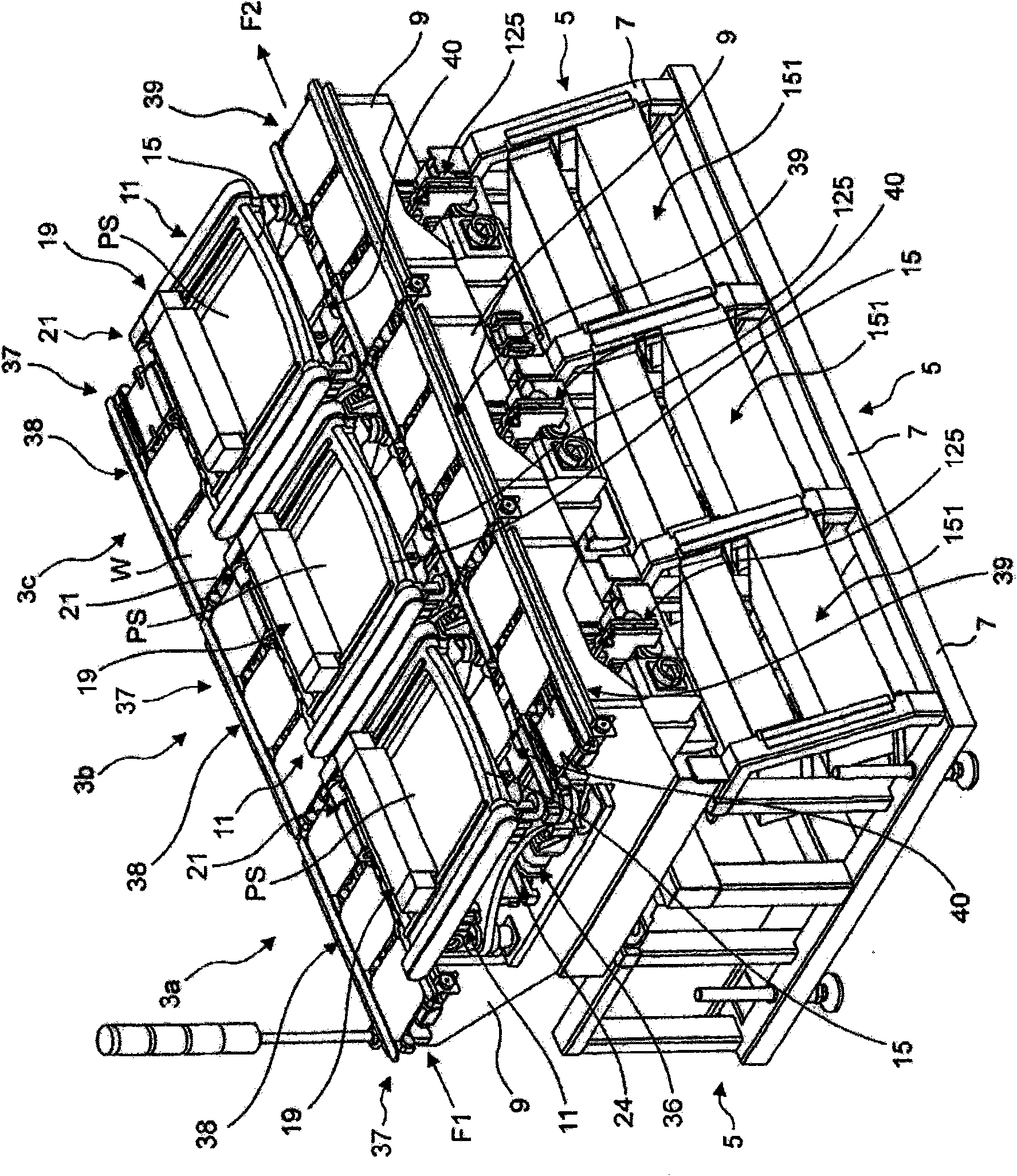

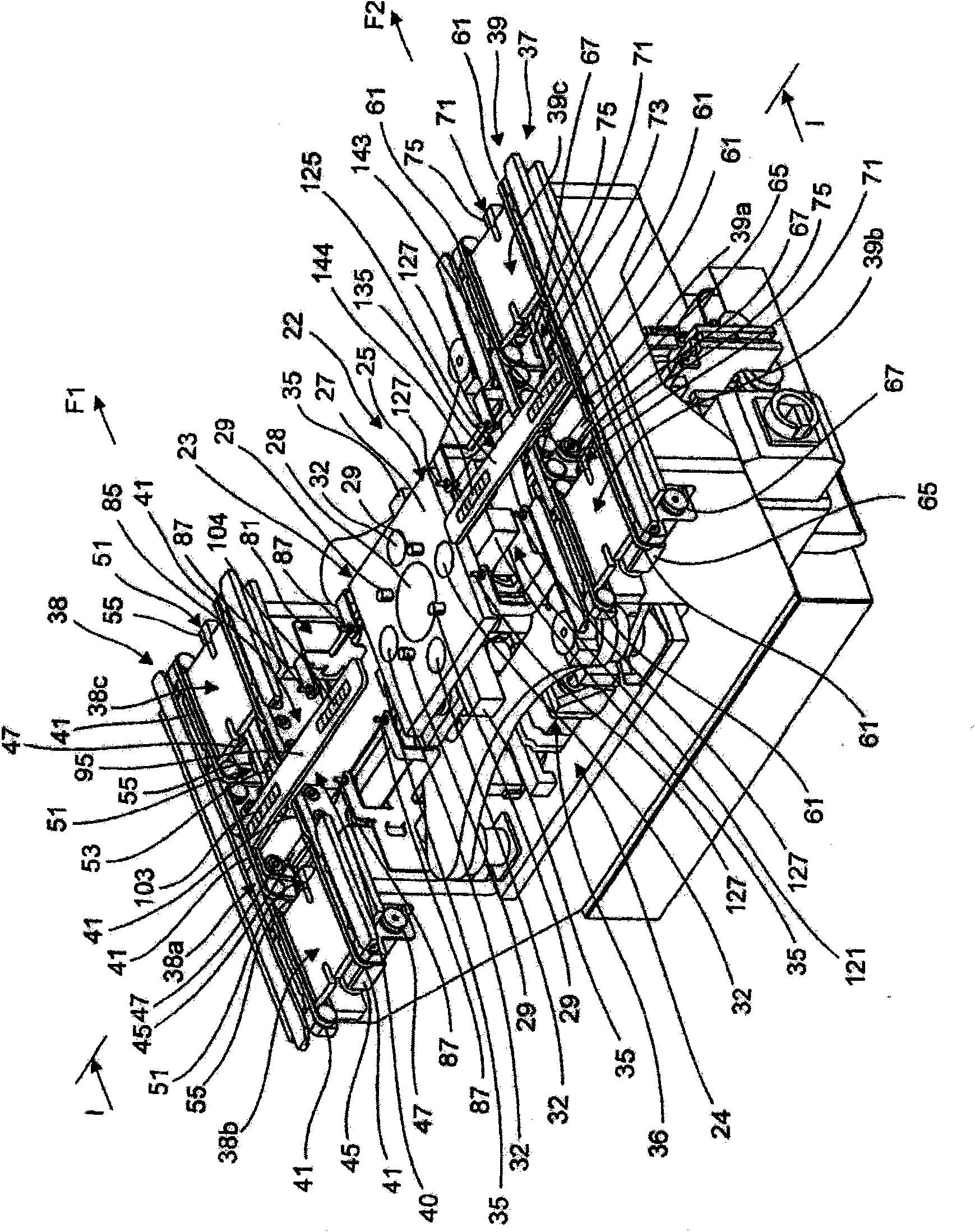

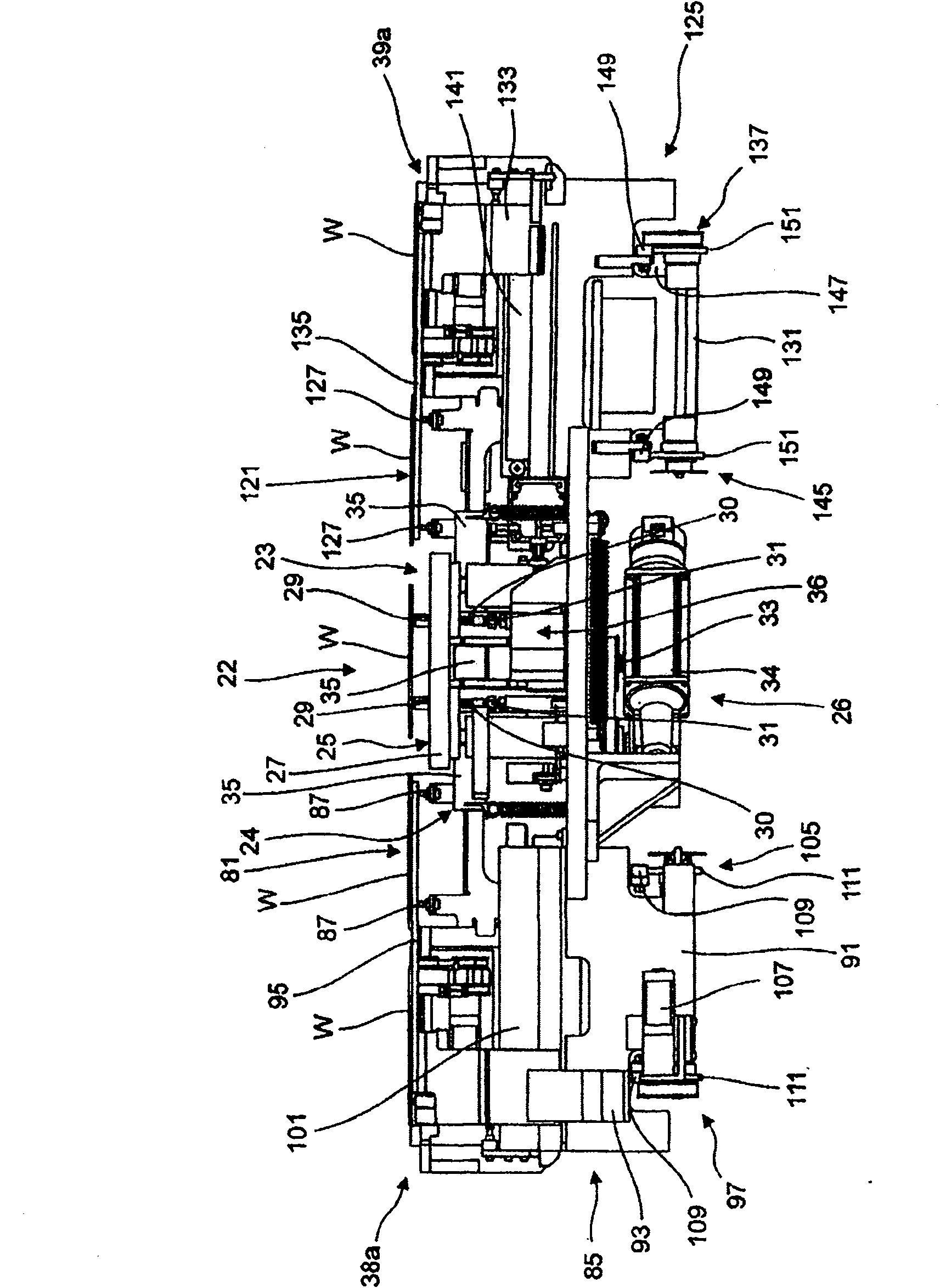

[0028] figure 1 4 shows a workpiece processing system, which in this embodiment is the screen printing system according to the first embodiment of the present invention.

[0029] The screen printing system comprises at least one workpiece processing module 3, in this embodiment a plurality of workpiece processing modules 3a, 3b and 3c, here a plurality of printing modules arranged in parallel, each printing module can be operated independently to A print medium deposit is printed onto the workpiece W.

[0030] Each printing module 3a, 3b, 3c comprises a support unit 5 comprising a base lower support 7 resting on the ground, in this embodiment a frame member, and an upper support 9 mounted on the lower support 7, In this example frame members.

[0031] In this embodiment, these lower supports 7 of the printing modules 3a, 3b, 3c are arranged in the form of an integral structure. In an alternative embodiment, the lower supports 7 of the printing modules 3a, 3b, 3c may be sepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com