Tubular actuator for driving a roller shutter

A technology of actuators and tubes, applied in the direction of windows/doors, door/window protection devices, shading screens, etc., which can solve the problems of interchangeability, fragility, reinforcement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

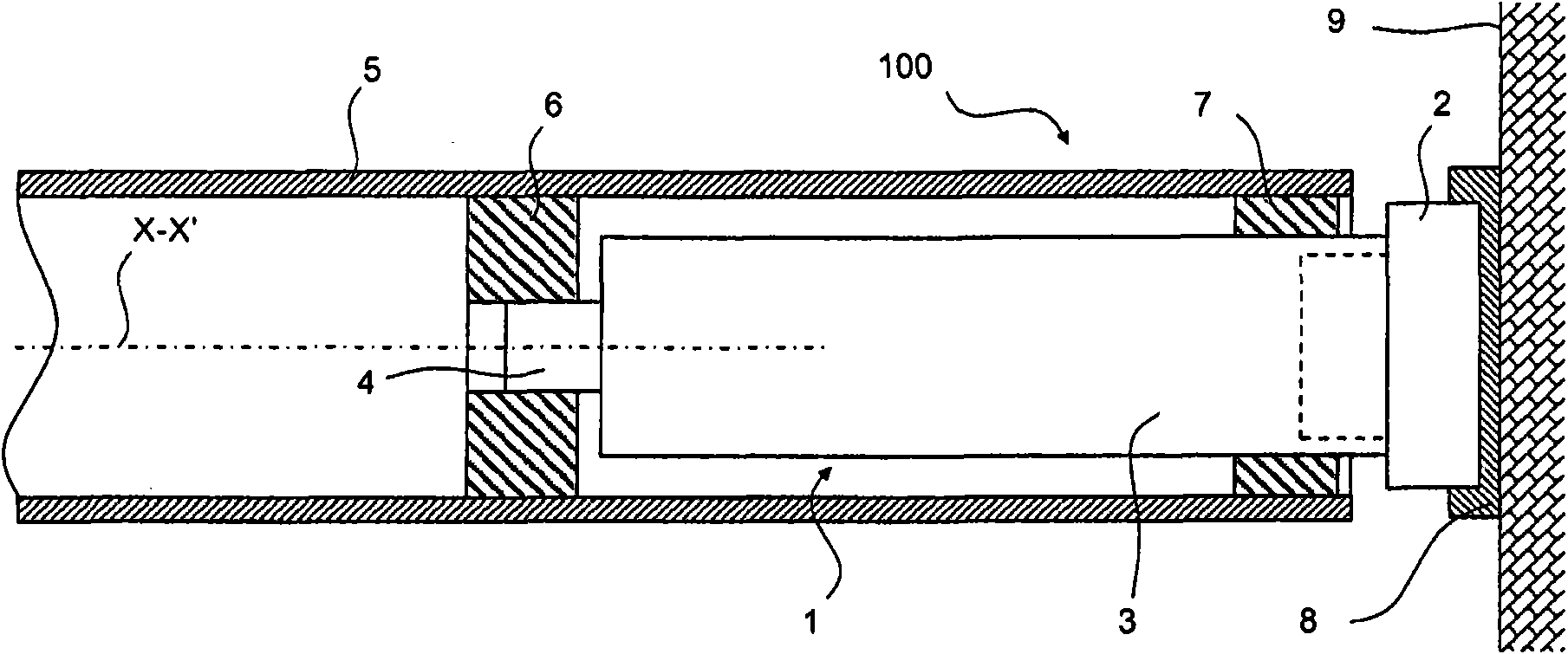

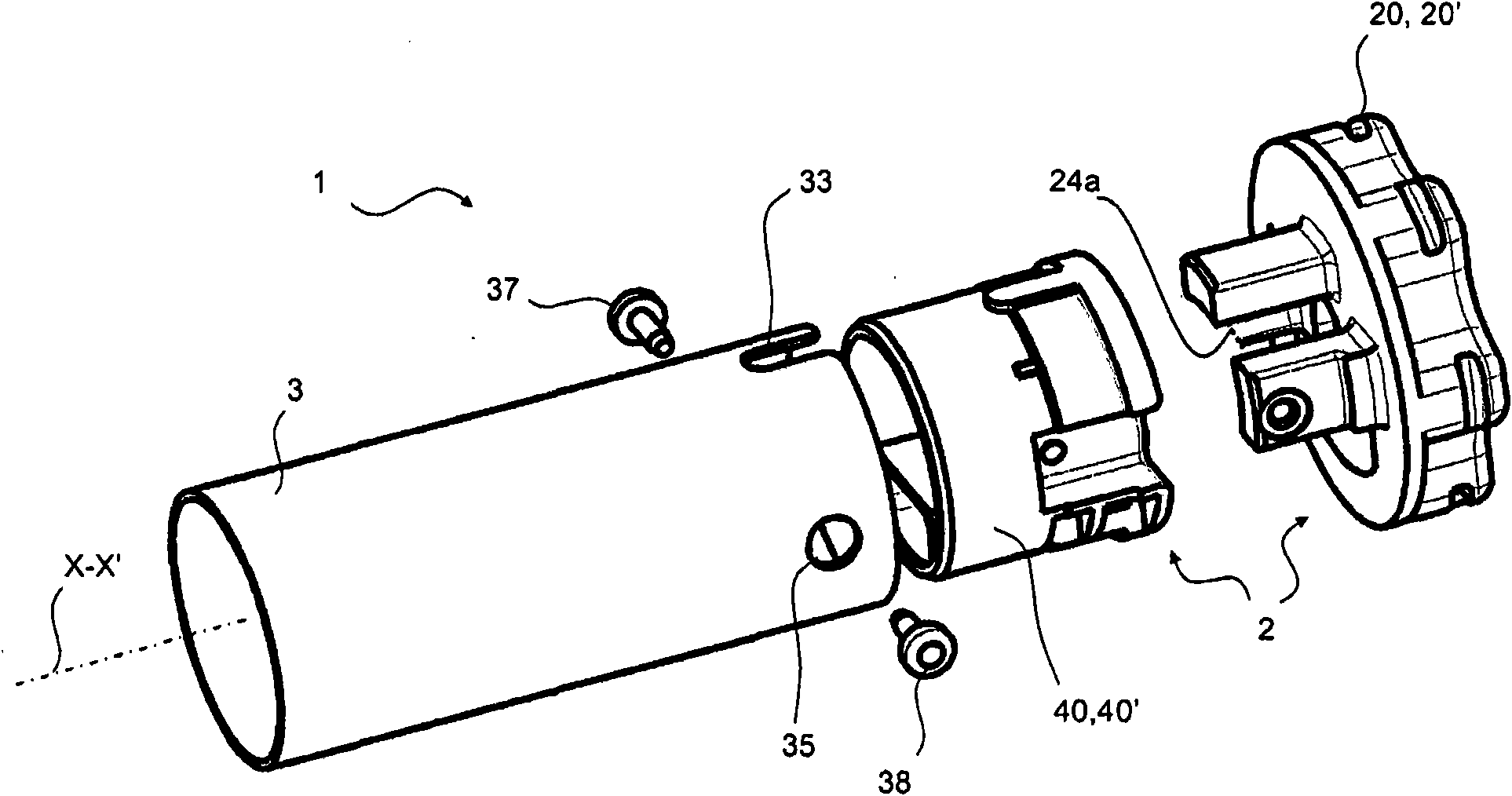

[0035] figure 1 A device 100 comprising a tubular actuator 1 is shown. Said tubular actuator comprises a fixed point part 2, a tubular body 3 and an output shaft body 4 which is movable in rotation according to the axis XX' of the tubular body of the actuator. The output shaft body is connected to a winding tube 5 in which the actuator is engaged by means of a drive wheel 6 . A bearing 7 allows the guidance of the winding tube in rotation on the tube of the actuator. A fixing fitting 8 connects the fixing point part to a frame 9 . A windable element, not shown, is fastened via one end to the winding tube. Fastening fittings are fixed to a frame, such as the structure of a building. It is preferably fixed directly on the frame. Furthermore, a fixed fitting is used to receive the fixed point part of the actuator. It has, for example, structural features for this purpose. The fastening fitting thus allows the indirect fastening of the fastening point part to the frame.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com