Rotary type-based fluid pattern spraying method

A rotating body and fluid technology, applied in the field of liquid or gas spraying, can solve problems such as difficulty in obtaining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

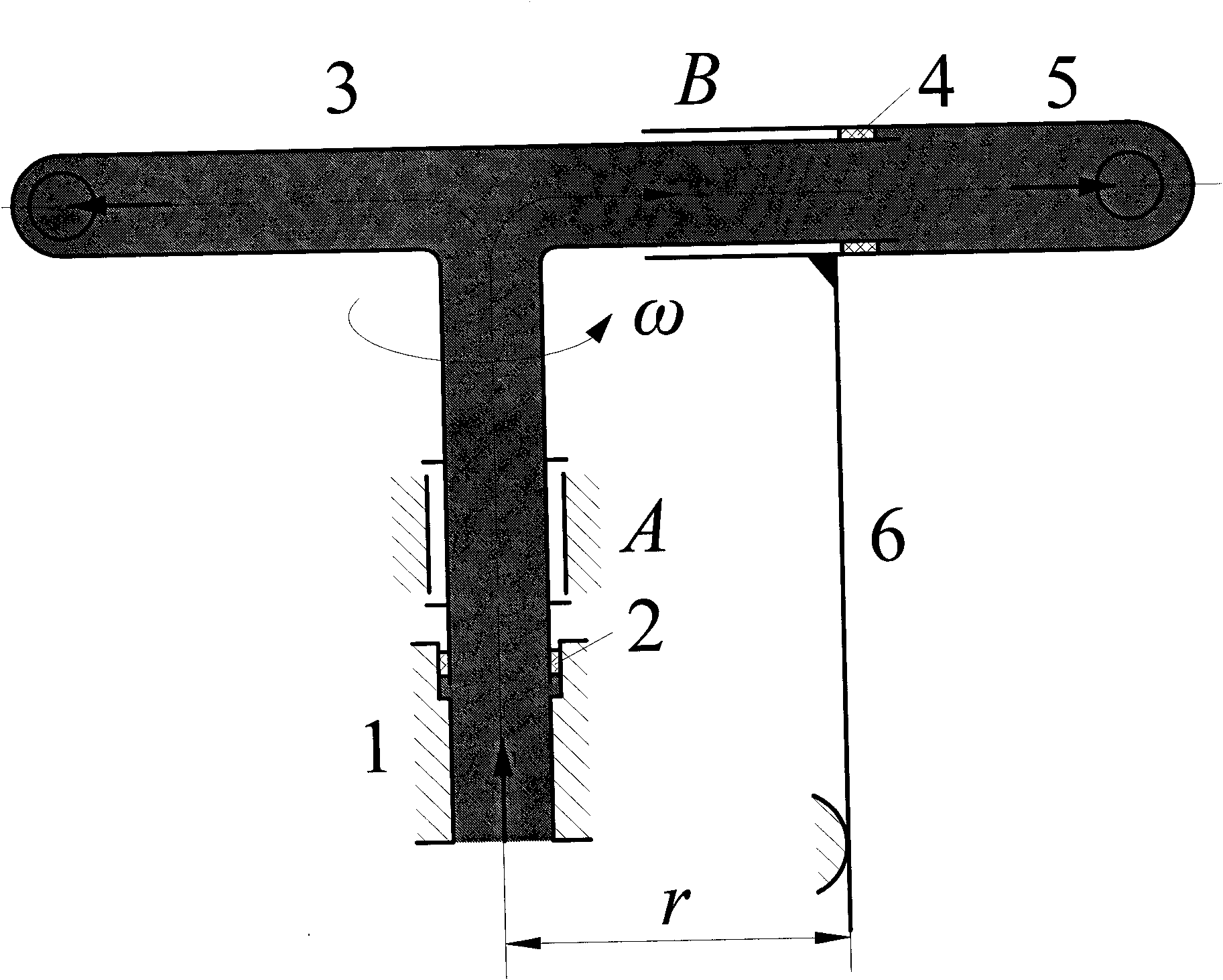

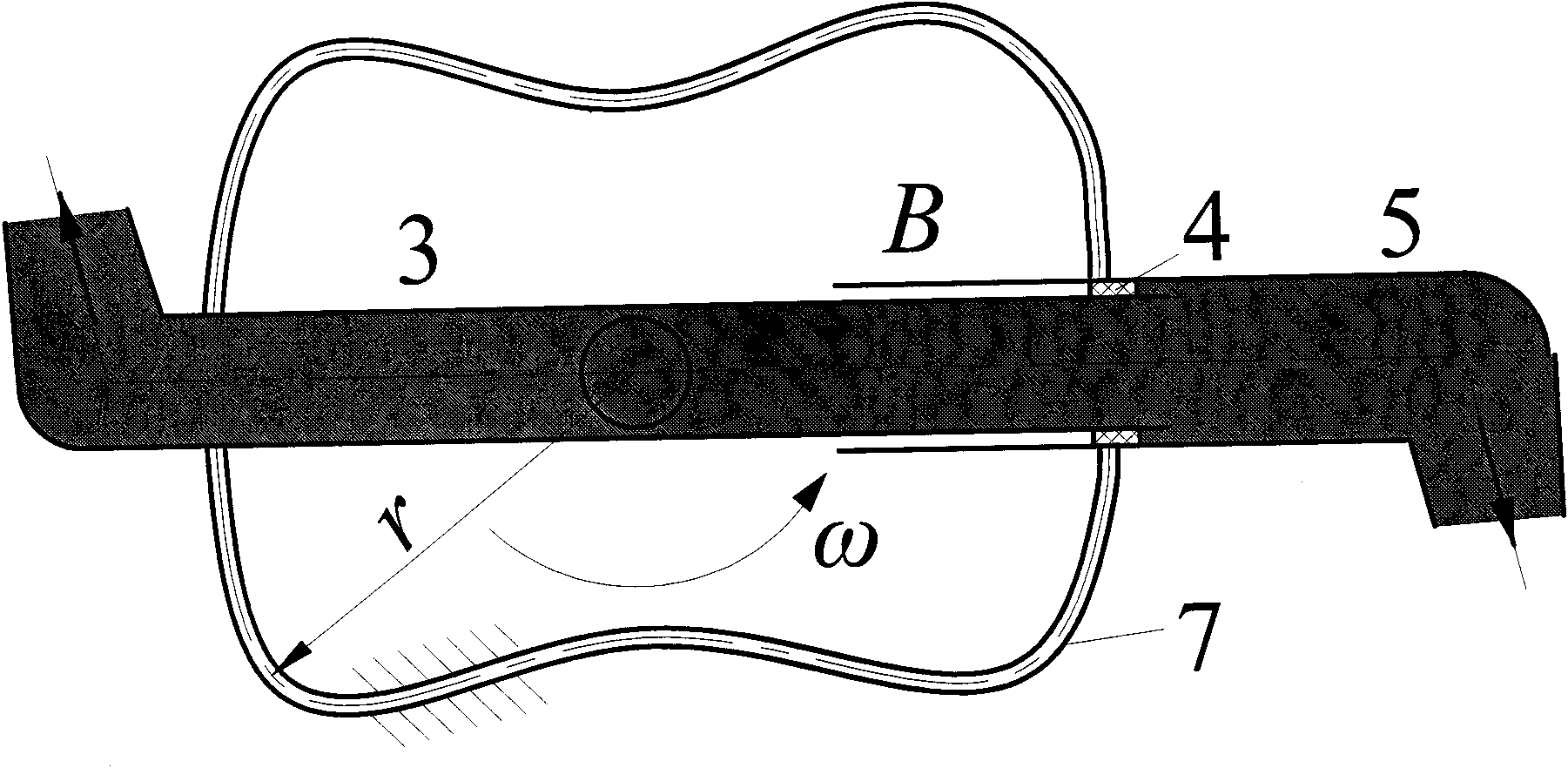

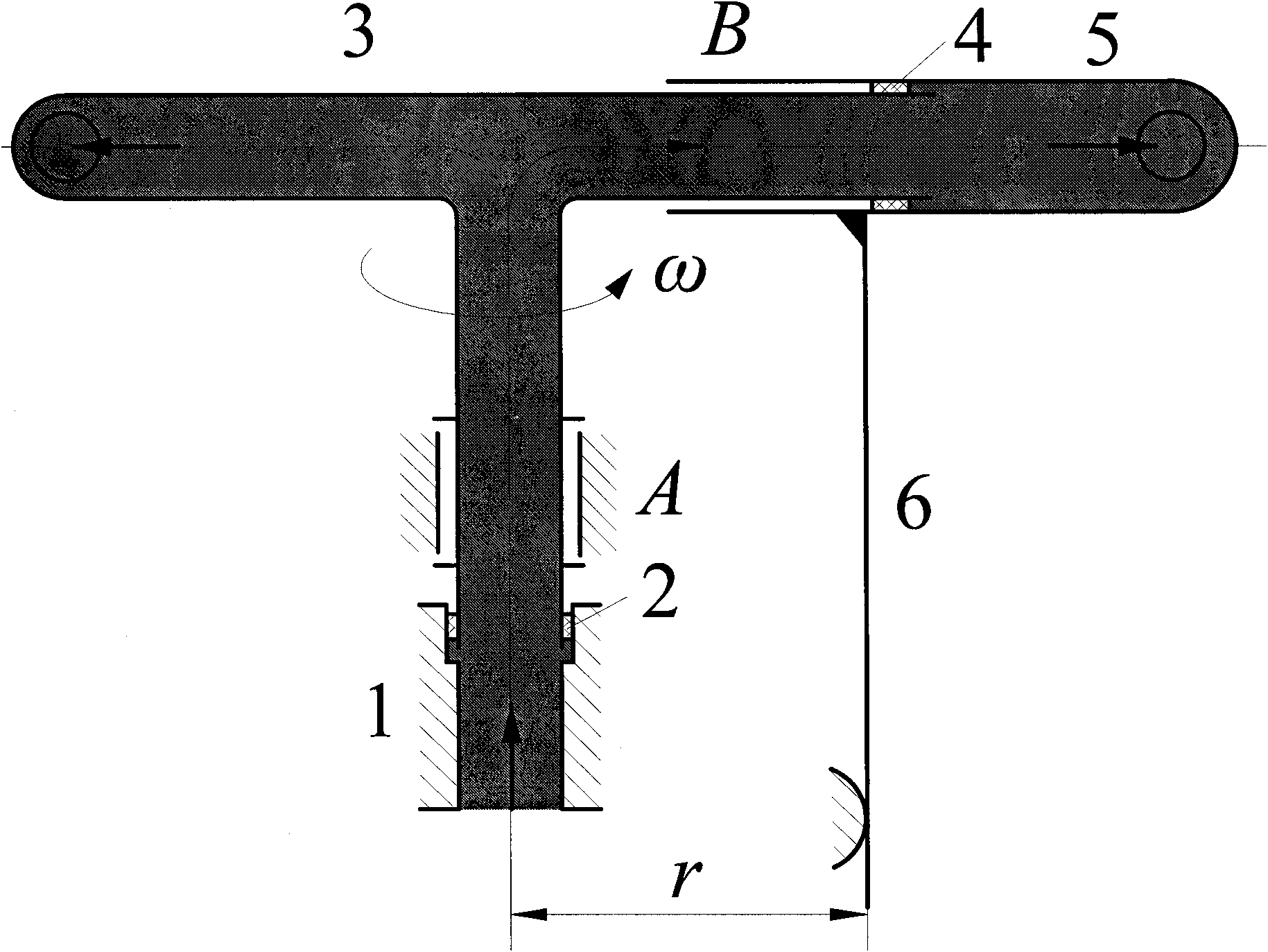

[0008] Below in conjunction with accompanying drawing, the patent of the present invention is further described by way of example.

[0009] attached figure 1 , attached figure 2 The composition principle of the rotary fluid pattern spraying mechanism is shown. The rotating body 3 is composed of an inlet pipe connected to two outlet branch pipes, wherein the inlet pipe is connected with the frame 1 through the rotating pair A, and a seal 2 is used to prevent fluid from leaking from the gap of the rotating pair A; one of the outlet branches The tube is provided with a deflected nozzle, and the other outlet branch pipe has no deflected nozzle, and is connected with the sliding nozzle 5 as the moving pair B, and is sealed 4 to prevent fluid from leaking from the moving pair gap. The sliding nozzle 5 is provided with a deflected nozzle. The variable-diameter annular groove is set on the frame 1 as the variable-diameter circular route 7, and forms a circle around the inlet pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com