Digital display module device of rivet/nut gun

A technology of digital display and warning device, used in measuring devices, instruments, hand-held tools, etc., can solve the problems of endangering the safety of operators, incomplete pulling, continuous pulling of studs or pulling caps, etc., and achieve the effect of prolonging the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

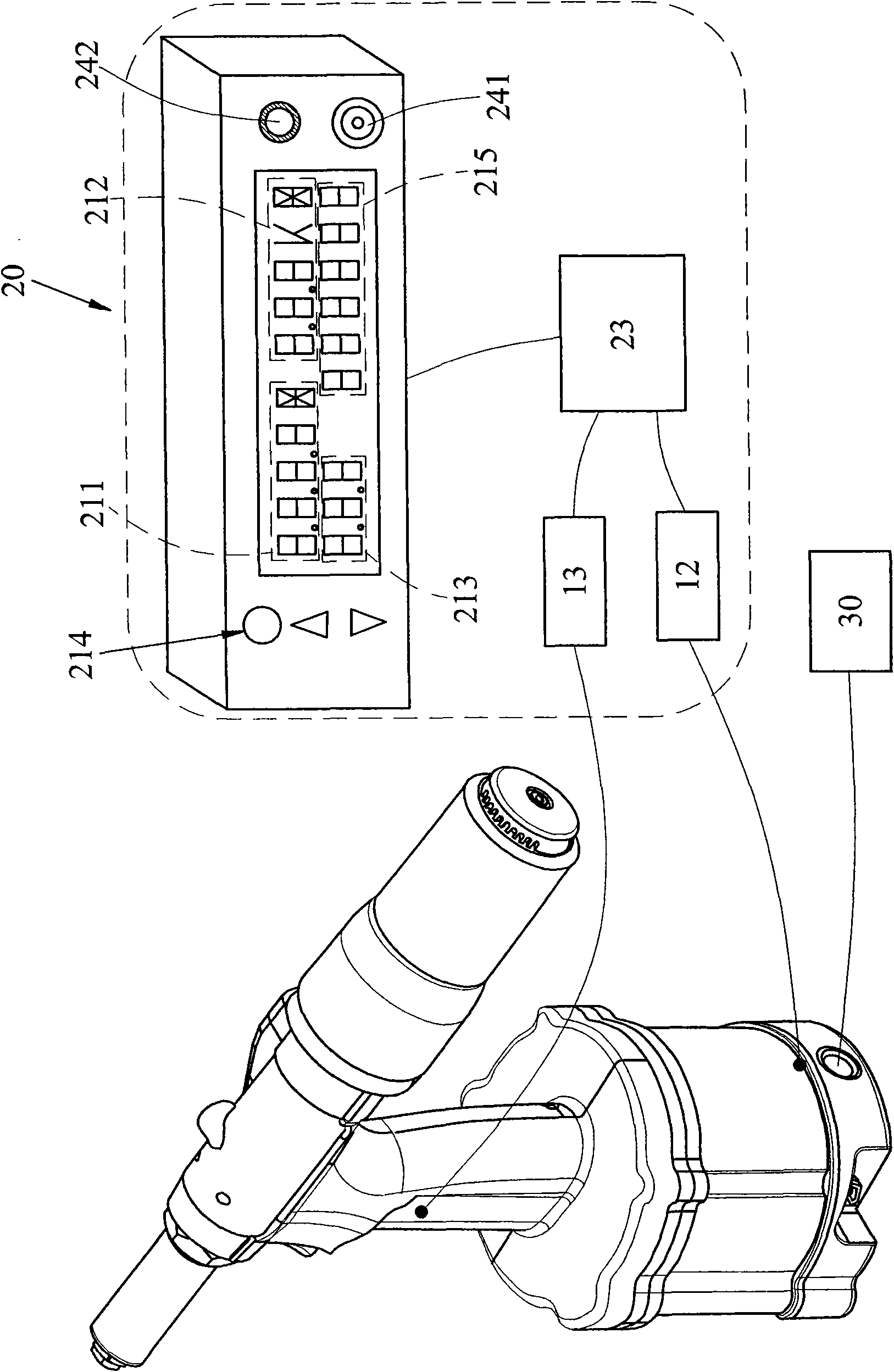

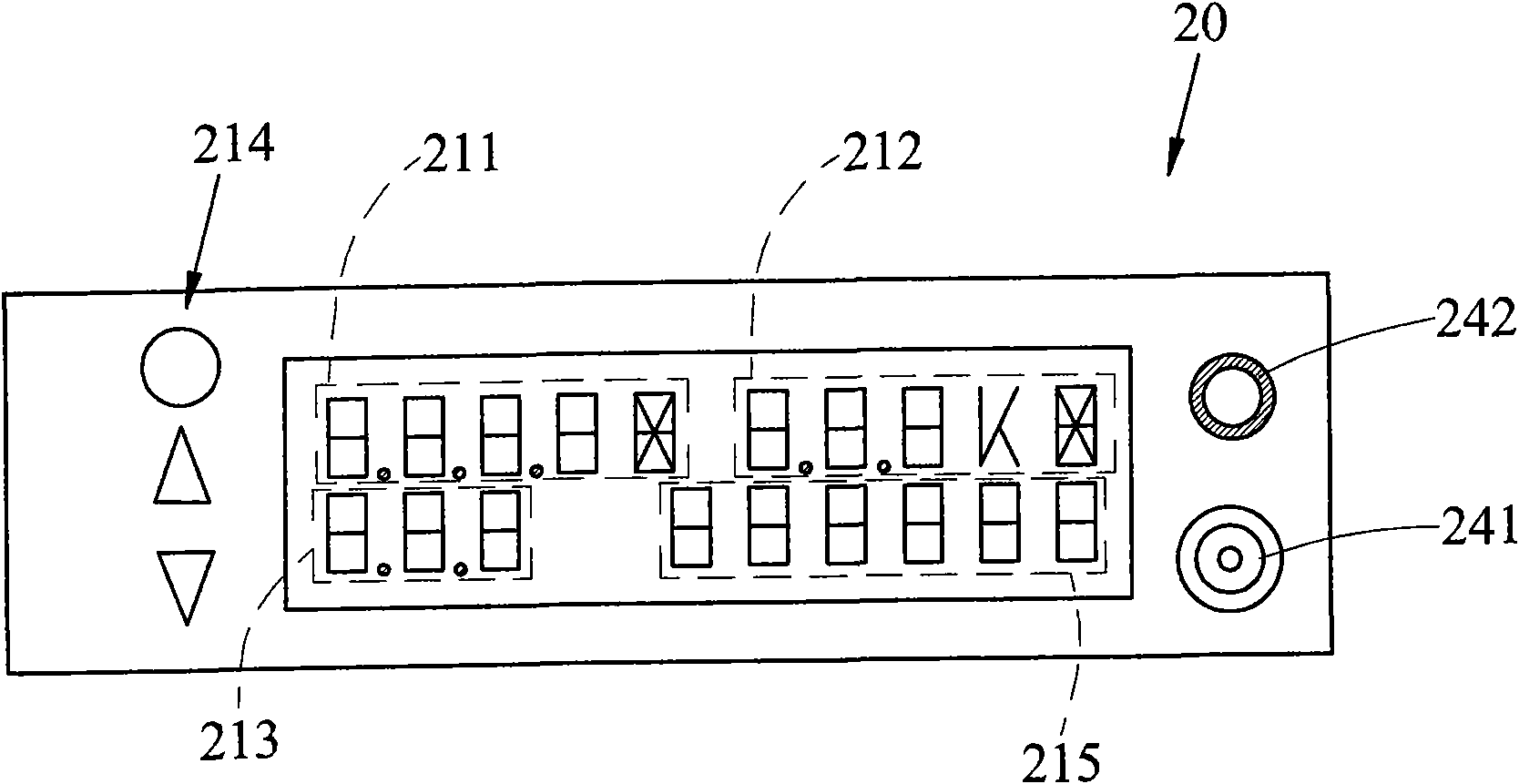

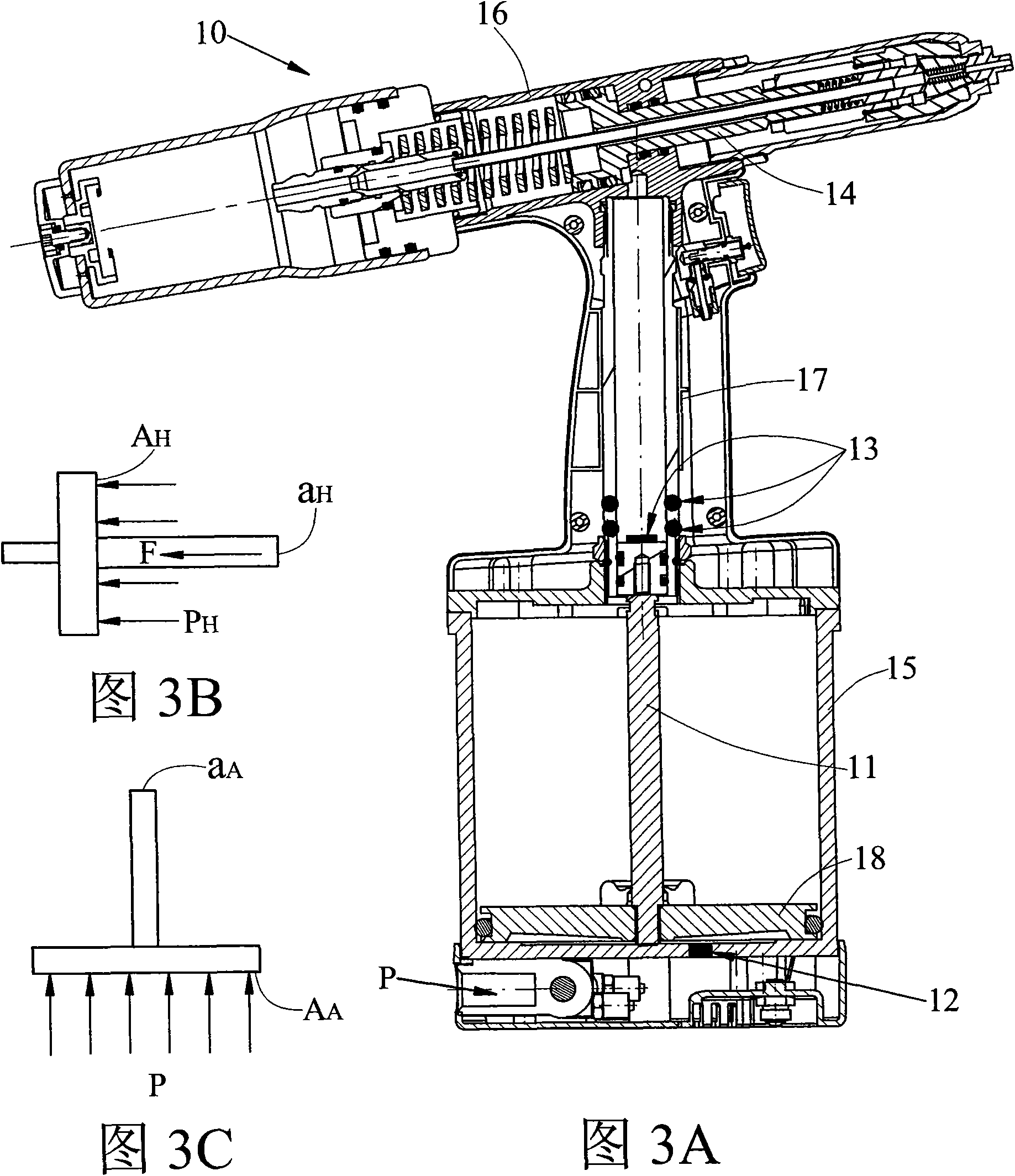

[0061] see Figures 1 to 13E As shown, the present invention provides a digital display module device for a rivet puller and a cap puller, comprising: a rivet / cap puller body and a digital display module device. Wherein, the nail / cap pulling gun body 10 refers to a pneumatically driven nail / cap pulling gun, an oil pressure driven nail / cap pulling gun or an air / oil pressure interlocking nail / cap pulling gun to compress Air or oil pressure is the power source 30 to actuate the blind riveting tool. Contain a pneumatic piston rod 11 (such as Figure 3A , 3B , 3C, 4A, 4B shown) or hydraulic piston rod 14 (such as Figure 5A , 5B shown), move in the pneumatic cylinder 15 or hydraulic cylinder 16 after being pressed, and cooperate with other components to do actions such as pulling nails or pulling caps.

[0062] The digital display module device 20 is connected to the main body 10 of the stud / cap gun for data transmission. The digital display module device 20 includes: a press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com