Linkage mechanism of mask machine and mask machine with linkage mechanism

A linkage mechanism and mask technology, which is applied in the field of mask machines, can solve the problems of poor product consistency, large differences in edge sealing positions, and time delays, and achieve the effects of simple installation, cost reduction, and strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but the embodiments do not limit the present invention in any form.

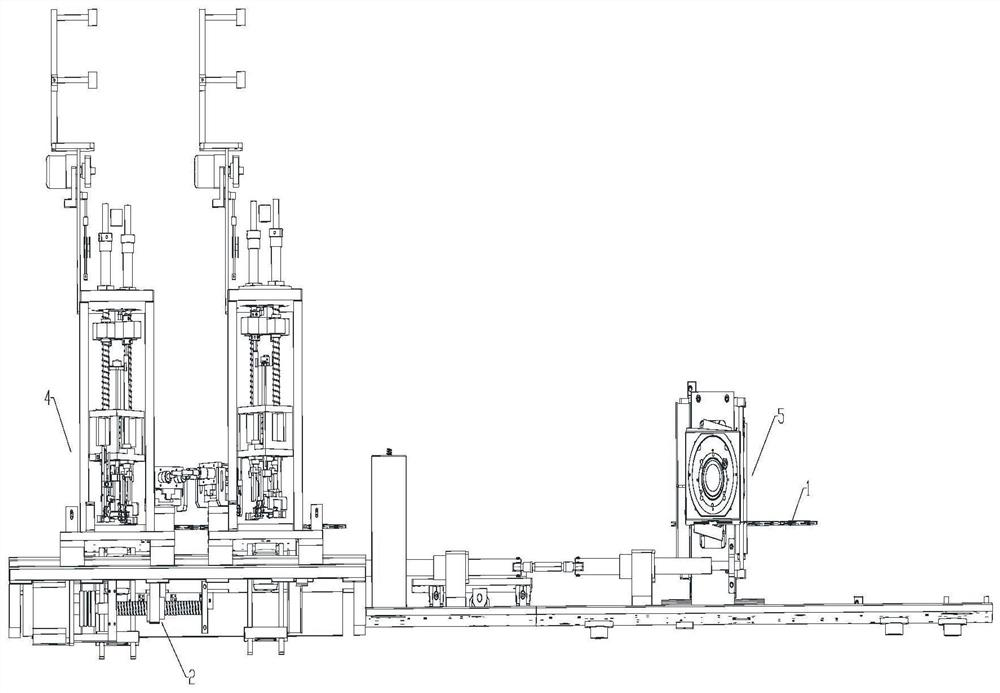

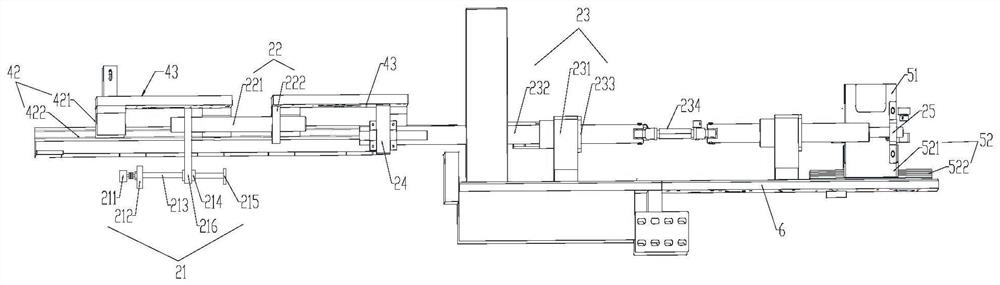

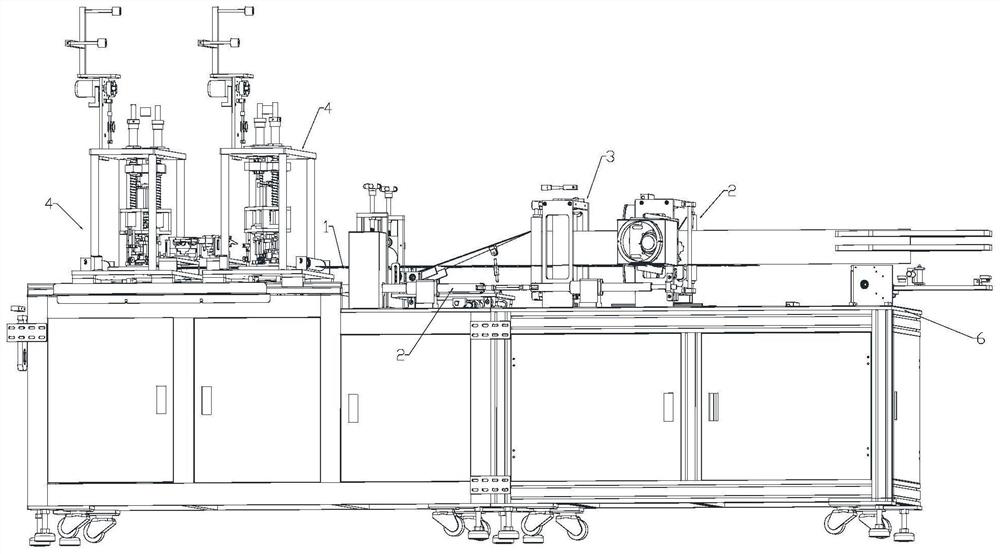

[0027] Such as Figure 1-3 As shown, one embodiment of the linkage mechanism of a mask machine includes a frame 6, a half-fold adjustment sub-organization, an edge-sealing sub-organization 5, a linkage assembly 2 and a welding ear band sub-mechanism 4, and the welding ear band sub-mechanism 4. The half-fold adjustment sub-mechanism 3 and the edge-sealing sub-mechanism 5 are distributed side by side on the frame 6 in the direction of the conveyor belt in sequence, and the linkage assembly 2 is located on the inner top of the frame 6 and is connected to the welding ear The belt sub-mechanism 4 and the edge-sealing sub-mechanism 5 are fixedly connected, and the linkage assembly 2 is used to synchronously drive the ear-welding belt sub-mechanism 4 and the edge-sealing sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com