Very-high-power connector

A technology of connectors and coaxial connectors, applied in the direction of connection, two-pole connection, two-part connection device, etc., can solve the problem of high power dissipation, achieve the effect of improving heat dissipation and optimizing size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

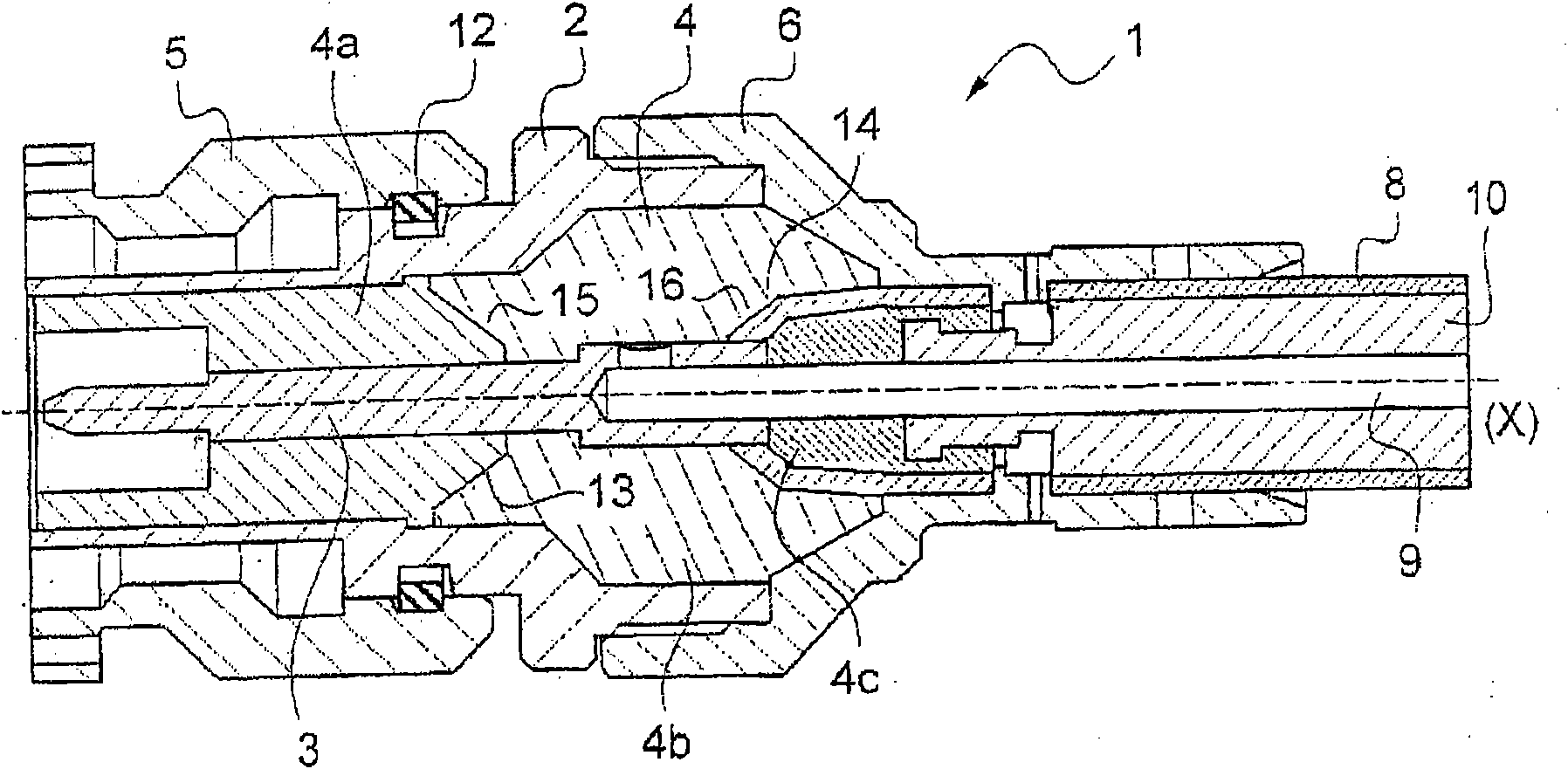

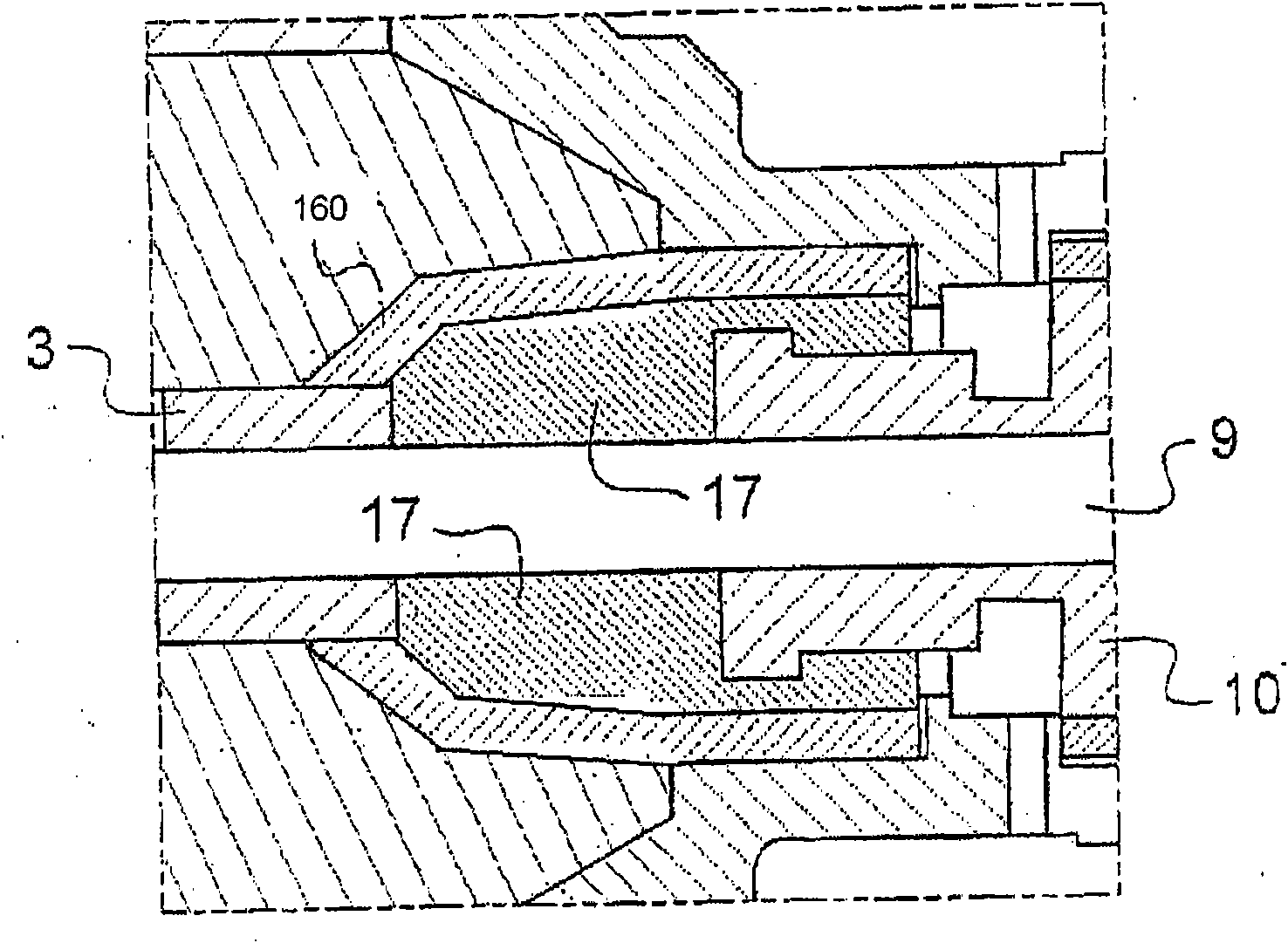

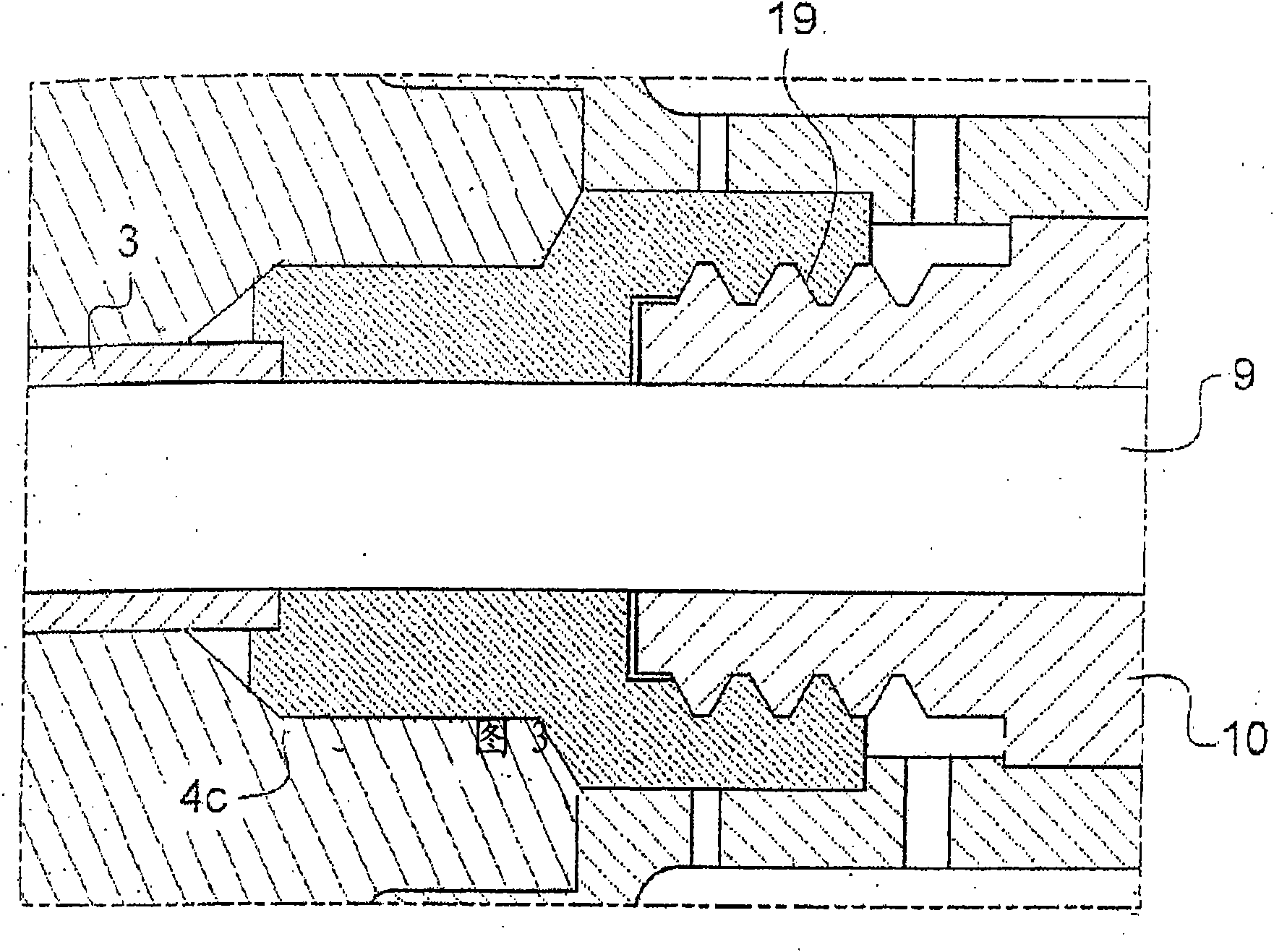

[0078] figure 1 An example of a coaxial connector, for example a TNC-type connector, with an axis X, generally indicated with reference numeral 1, is shown. This coaxial connector 1 in this example comprises a main body 2 made in one piece and a central contact 3 fitted in the main body 2 with an insulating member 4 interposed between the main body 2 and the central contact 3 . A cylindrical channel 7 is formed in the insulator 4 to accommodate a central contact 3 which, in the example shown, has a substantially cylindrical outer shape.

[0079] In the example described, the coaxial connector 1 also includes a cap 5 fitted to the front of the body 2 and a sleeve 6 fitted to the rear of the body 2 . In the example described, the cap 5 defines the front of the connector 1 adapted to be coupled to a complementary coaxial connector, while the sleeve 6 defines the front of the connector 1 for fitting on a coaxial cable 8 . rear.

[0080] Such as figure 1 As shown, a coaxial cab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com