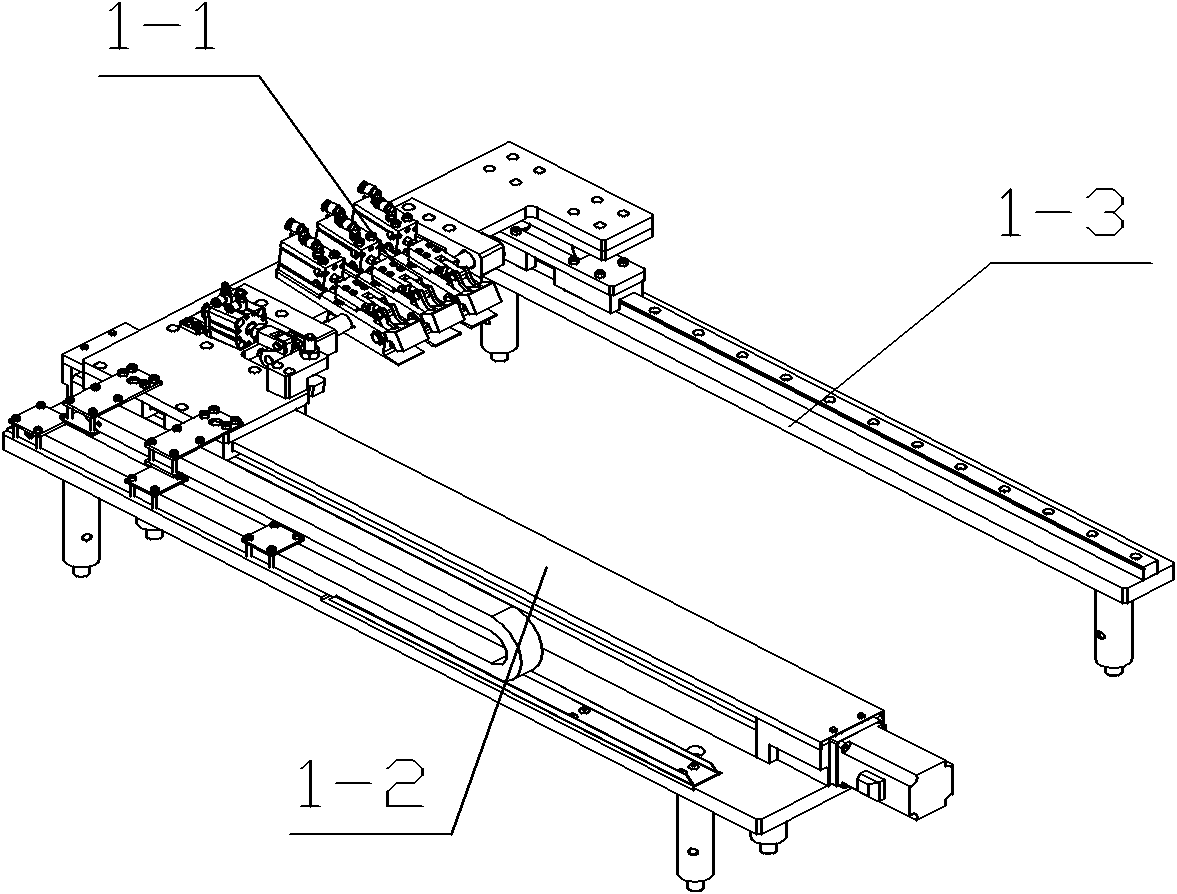

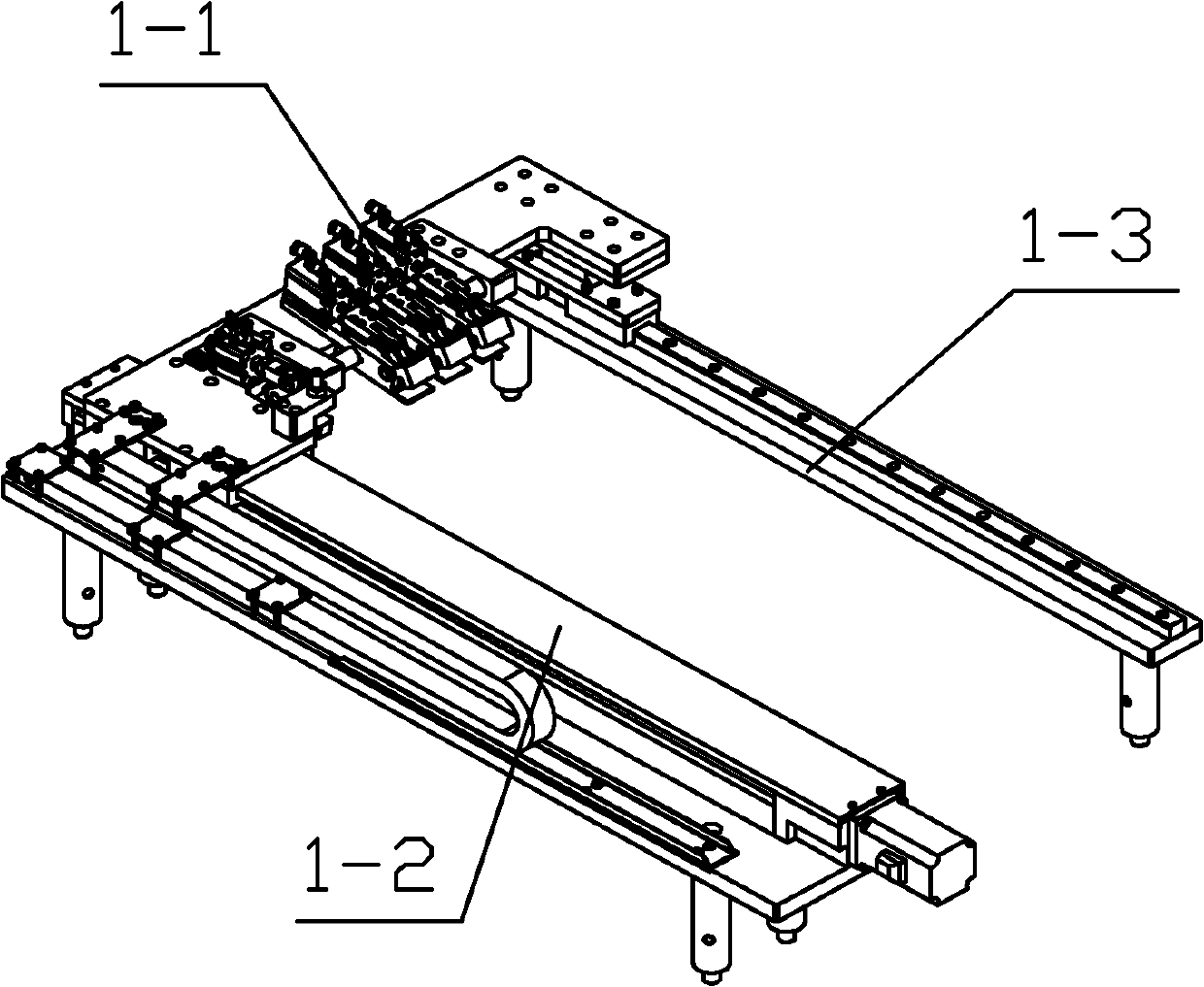

Solder strip drawing and releasing mechanism

A technology of welding strip and clamping jaw, applied in the field of welding strip pulling and releasing mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

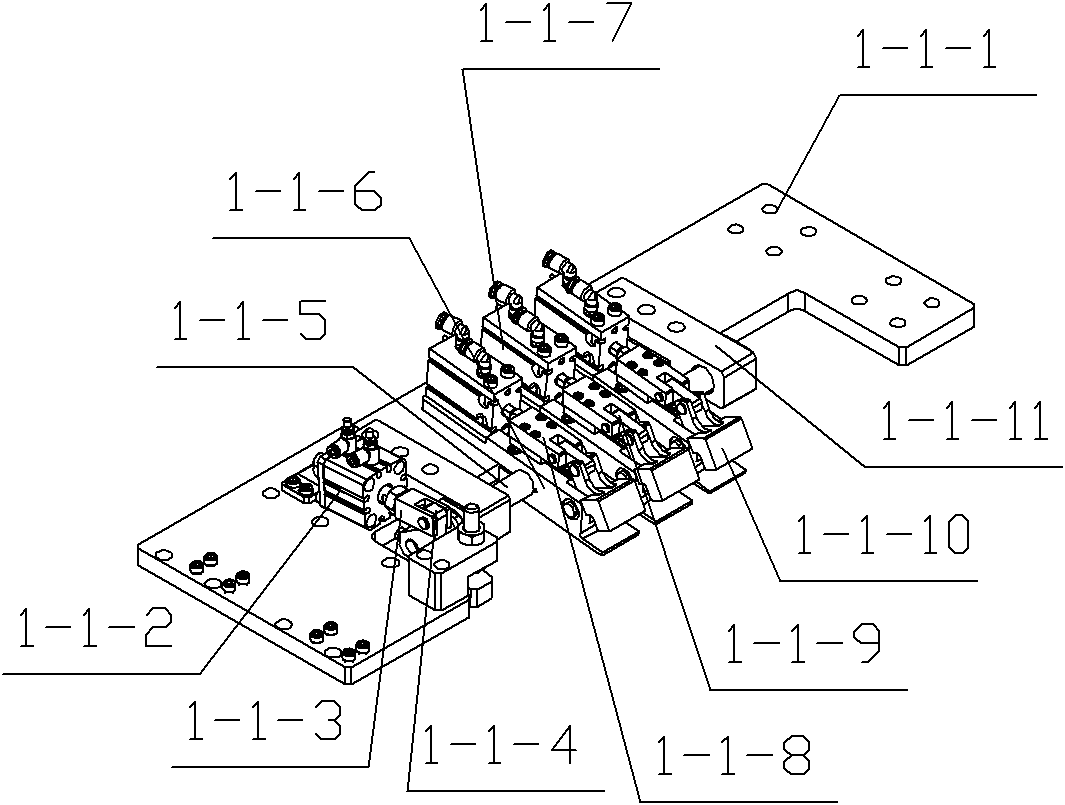

[0012] The motor in the ribbon pulling and releasing mechanism drives the air claw assembly 1-1 to move to clamp the ribbon; according to the set moving distance, the air claw assembly 1-1 stops moving after reaching a fixed length, and waits for the cutting mechanism to cut off the ribbon ; In the ribbon pulling and releasing mechanism, the motor drives the air claw assembly 1-1 to move the cut ribbon to the placement position, and the rotating cylinder 1-1-2 drives the rotating shaft 1-1-5 to rotate, so that the jaws support 1- The gripper fingers of 1-6 move down, and then the gripper fingers move the cylinder 1-1-7 to drive the gripper fingers 1-1-10 to move, so that the gripper fingers 1-1-10 will loosen the welding ribbon Place it on the object to be welded. The rotary moving cylinder 1-1-2 drives the rotating shaft 1-1-5 to rotate, so that the jaw fingers of the jaw support 1-1-6 move upward; the motor in the welding belt pulling mechanism drives the air claw assembly 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com