Isolated key-check lock cylinder with mutual-stacking structure

A marble lock cylinder and marble technology, which is applied in the field of the interlocking structure to isolate the key check marble lock cylinder, can solve problems such as frictional resistance, and achieve the effect of smooth unlocking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

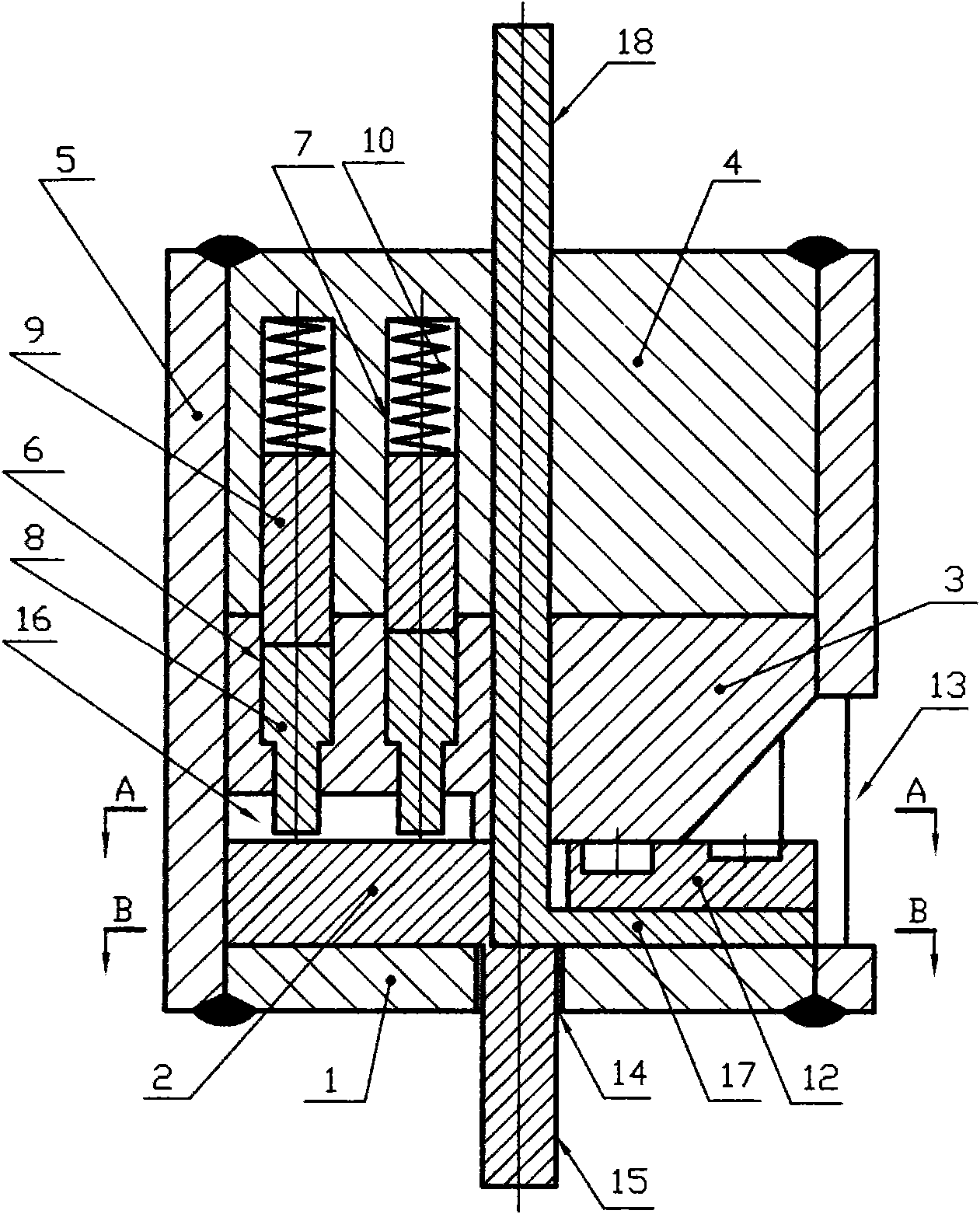

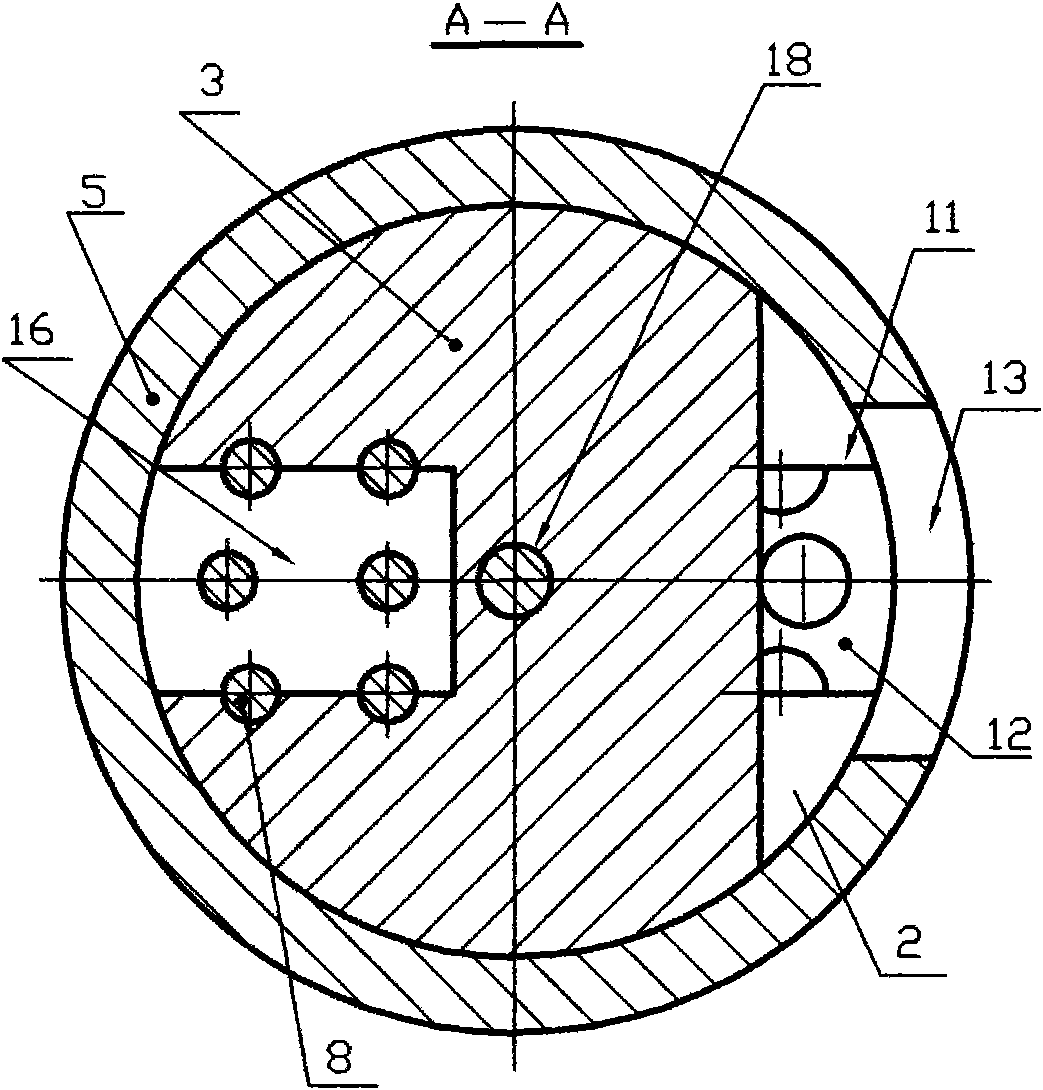

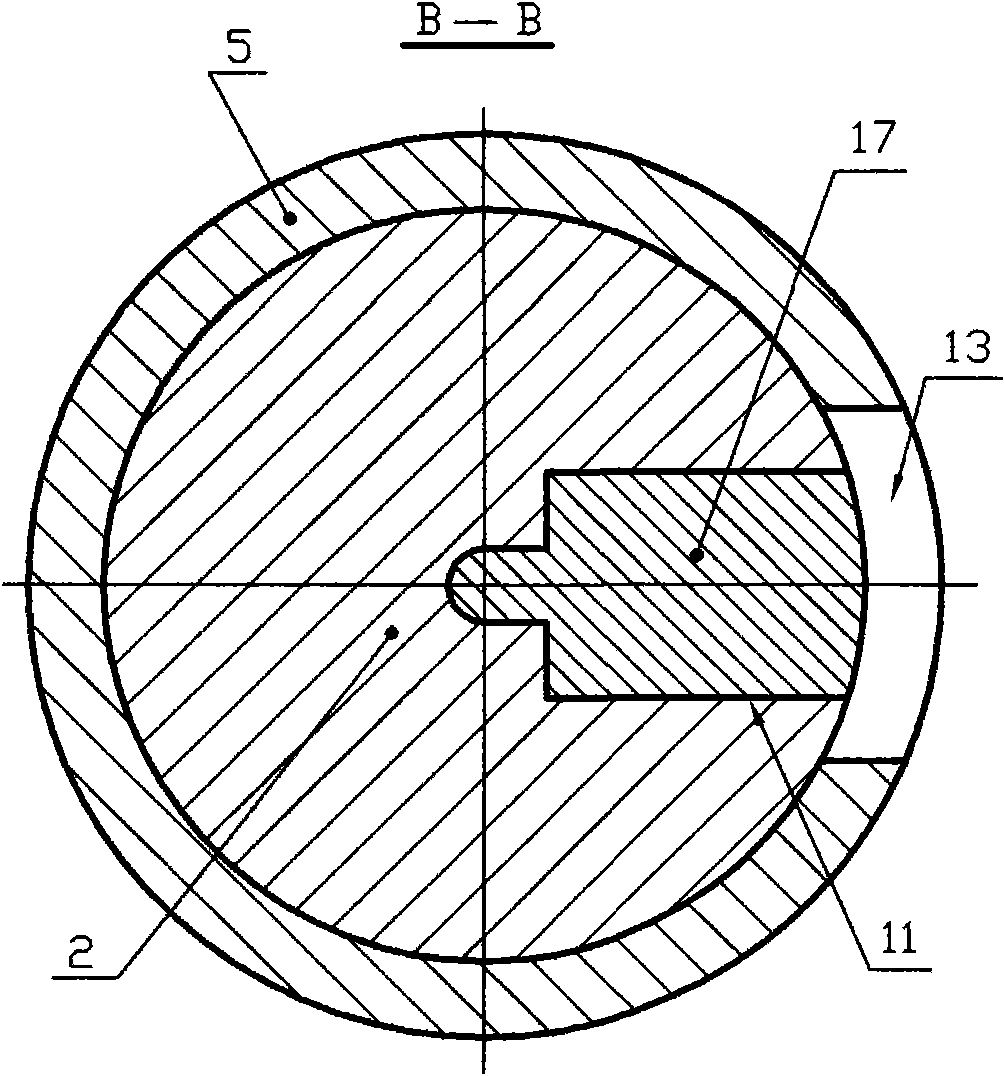

[0017] Such as Figure 1 to Figure 7As shown, the active rotating core guard plate [1], the driven rotating core guard plate [4], and the rotating core protection round tube [5] are fixedly combined to form a fully enclosed structure of the rotating core protective shell, and the rotating core protective shell is formed A cylinder-shaped cavity is provided to accommodate the active rotating core [2] and the driven rotating core [3]; the lower marble hole [6] processed on the driven rotating core [3] and the driven rotating core guard plate [4] The upper marble hole [7] of the upper processing is equipped with a lower marble [8], an upper marble [9], and a pin spring [10] to form a key inspection mechanism; in the key transmission gap of the active rotating core [2] [ 11] is inserted with a key [12], and the key [12] has a pit that accepts the inspection of the lower pin [8]; [13] inserted into the key delivery notch [11] or pulled out from the key delivery notch [11]; relying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com