Light emitting diode driving circuit

A technology of light-emitting diodes and light-emitting diode lights, which is applied to instruments, static indicators, etc., and can solve problems such as high maintenance costs, LCD panel screens not bright, and user costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

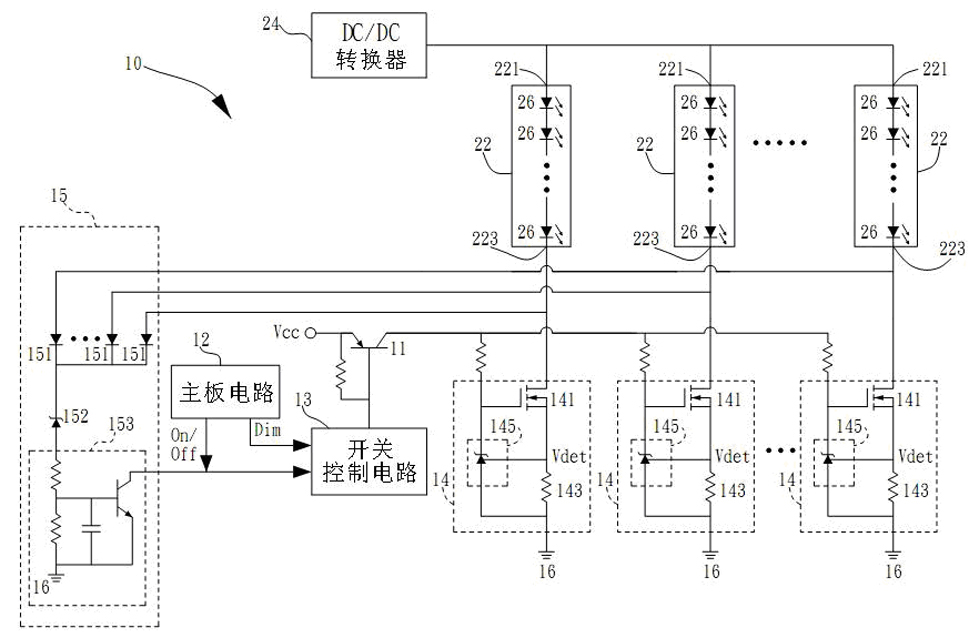

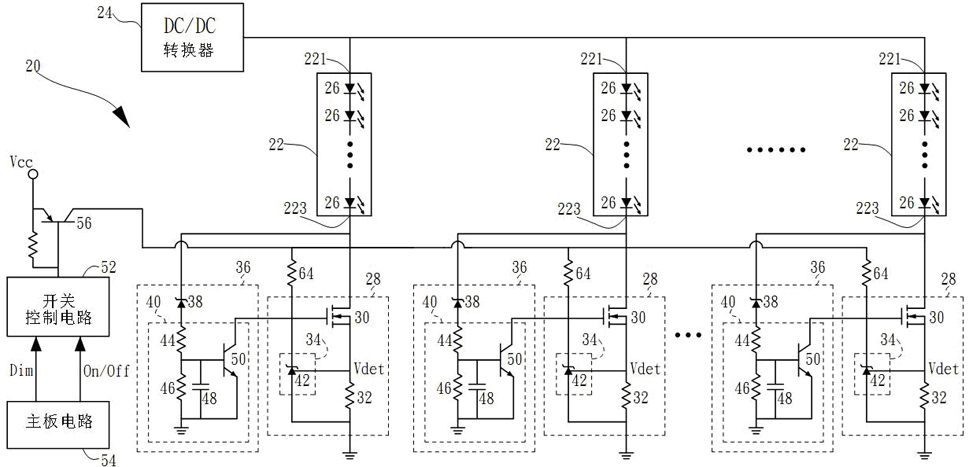

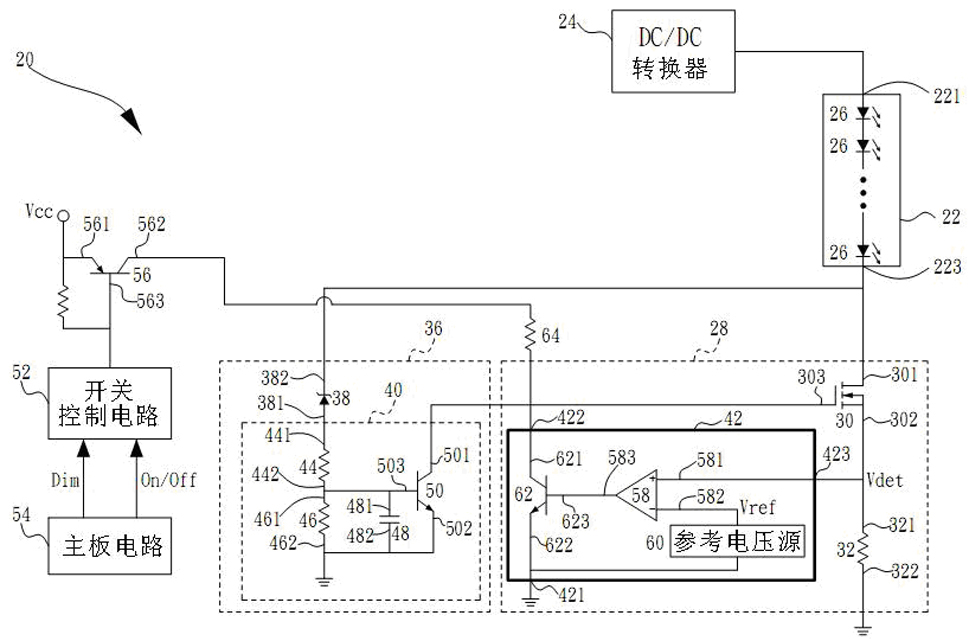

[0053] see figure 2 , figure 2 It is a circuit diagram of a preferred embodiment of the LED driving circuit 20 of the present invention. In general, the LED driving circuit 20 can be applied to liquid crystal display products using a light source composed of LEDs as a backlight source. The LED driving circuit 20 is used to drive a light source composed of a plurality of LED strings 22 , wherein each LED string 22 includes a plurality of LEDs 26 coupled in series. Each LED light string 22 has an input end 221 and an output end 223 respectively. The input ends 221 of all LED light strings 22 are coupled to a DC voltage output by a DC / DC converter 24 .

[0054] The LED driving circuit 20 includes a plurality of constant current circuits 28 , wherein each constant current circuit 28 includes a transistor 30 , a detection resistor 32 and a feedback circuit 34 . The transistor 30 and the detection resistor 32 are coupled in series between the output terminal 223 of a correspond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com