Dust-removing and pressure-stabilizing cooler and sample gas processing method thereof

A cooler and sample gas technology, applied in the preparation of test samples, etc., can solve problems such as single function, long lag time, and complex structure, and achieve the effects of shortening lag time, strong reliability, and wide universal range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

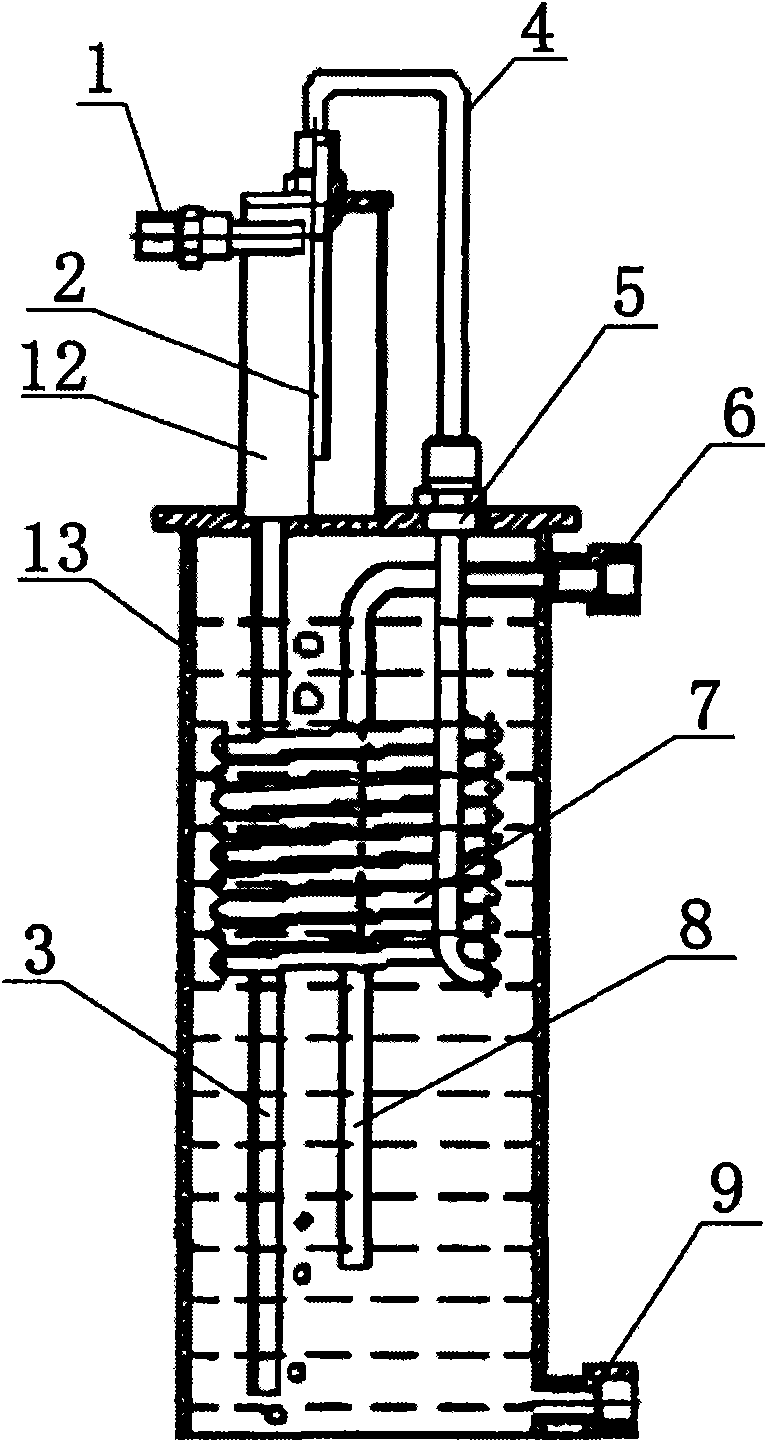

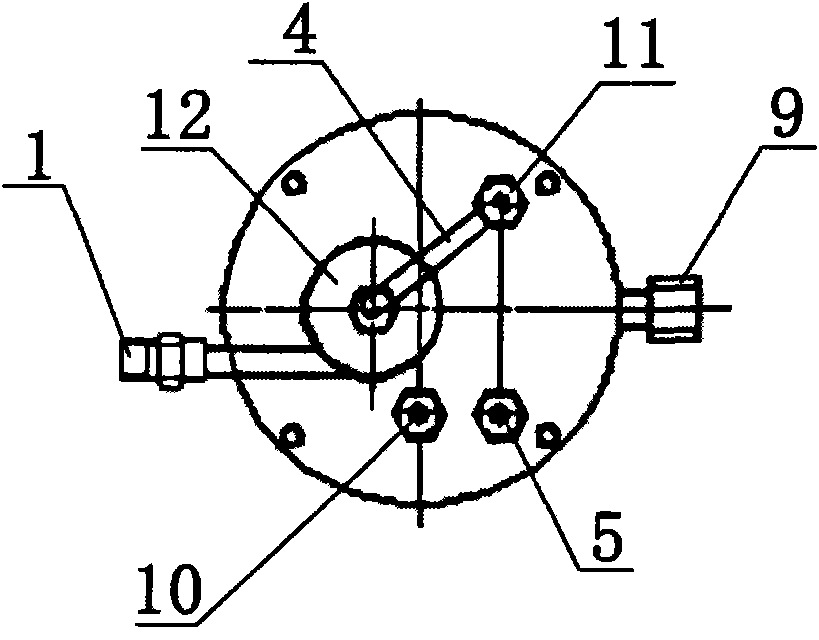

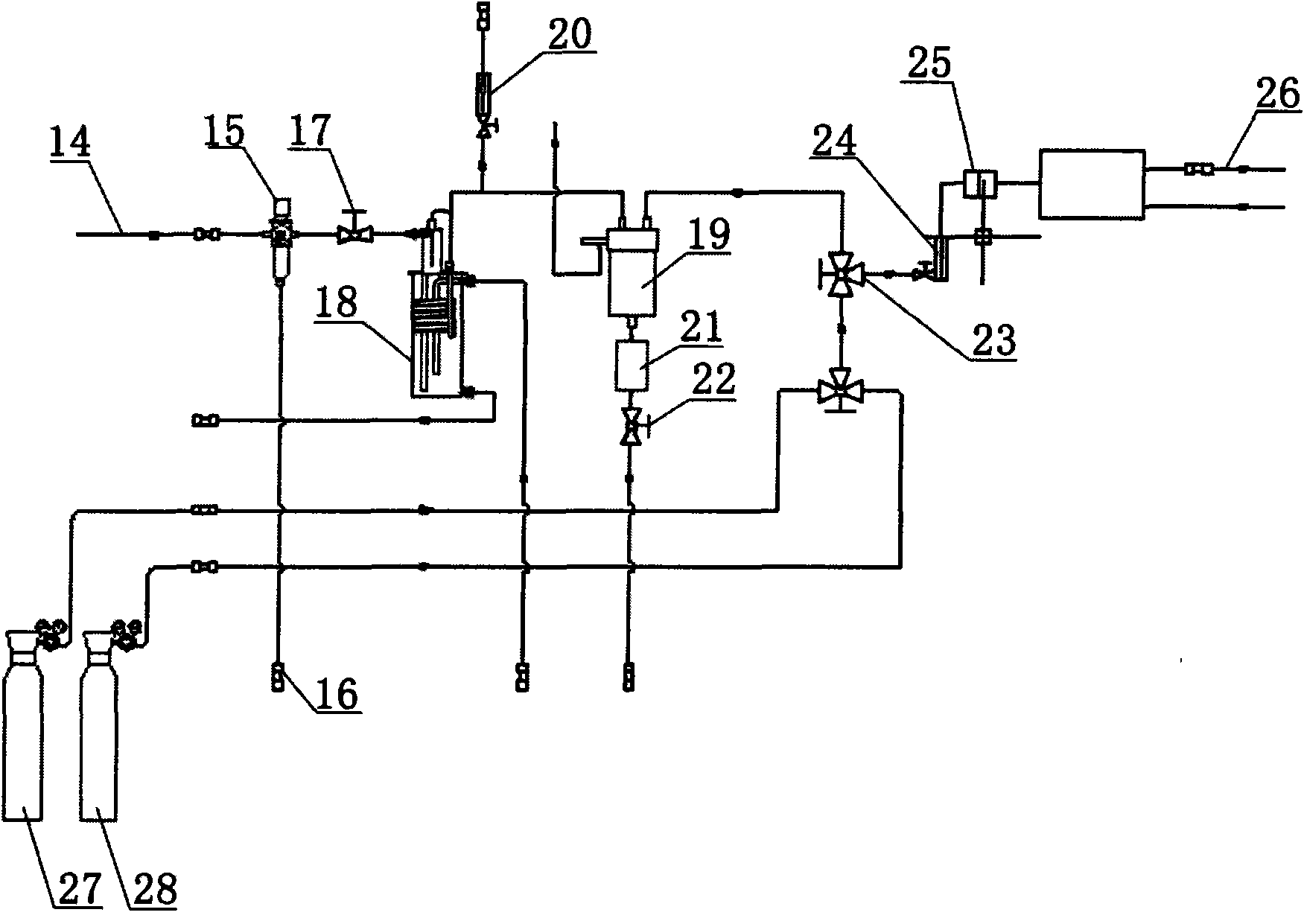

[0029] Examples see figure 1 , figure 2 As shown, this dedusting and stabilizing cooler includes a cylinder body, a cooling pipe inside the cylinder body, and a sample gas inlet 1 and a sample gas outlet 5 on the cylinder body. The cylinder body is divided into an upper cylinder 12 connected to each other and a The lower cylinder 13, the diameter of the lower cylinder can be φ102mm, and the height is 390mm. The upper cylinder is connected with the lower cylinder through the branch pipe 3 at the bottom. The branch pipe extends into the liquid inside the lower cylinder at a level of 220-250mm. or coolant. The sample gas inlet 1 extends tangentially into the upper cylinder and is perpendicular to the inner tube 2 inside the upper cylinder. The lower end of the inner tube extends vertically into the upper cylinder, and its upper end passes through the top cover of the upper cylinder and passes The connecting pipe 4 and the connection port 11 on the top cover of the lower cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com