Process for production and quantitation of high yield of biobutanol

一种丁醇、微生物的技术,应用在定量评估丁醇,高效液相色谱领域,能够解决运行时间长、不能用于分析大量的样品等问题,达到减少时间的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0117] Example 1: Biology and Growth Conditions

[0118] Clostridium acetobutylicum ATCC 10132 was grown in 125 ml anaerobic flasks containing 50 ml anaerobic sugar (AnS) medium with the following composition (gL -1 ): glucose (20.0), peptone (10.0), yeast extract (5.0), K 2 HPO 4 (3.0), NaCl(1.0), (NH 4 ) 2 SO 4 (1.0), CaCl 2 .2H 2 O(0.2), MgCl 2 .6H 2 O(0.2) and Na 2 CO 3 (1.0), pH 6.5.

[0119] The medium was sterilized (15 minutes, 121° C.) in glass vials sealed with butyl rubber stoppers. Fill the headspace with N 2 , and add Na 2 S.9H 2 O (0.02%) to remove traces of dissolved oxygen (Samuelov et al. 1991; Lee et al., 2000). The reduced medium was inoculated using a 2% inoculum size and incubated at 37 ± 1 °C for 96 h with intermittent gentle shaking.

Embodiment 2

[0120] Example 2: Method for evaluating butanol

[0121] After the desired incubation period, the culture was removed from the sealed vial using a sterile disposable syringe and centrifuged at 8000 xg for 10 minutes in an Eppendorf centrifuge (model 54151). Filter the supernatant through a 0.45 μ filter. At 37 °C, using acetonitrile and 0.5 mM H 2 SO 4 (1:9) as mobile phase and samples (20 μl) were analyzed by HPLC (Ehrlich et al, 1981) on a PRP 300X column (Hamilton) at a flow rate of 1.5 ml / min. Butanol was detected using an RI detector.

Embodiment 3

[0122] Embodiment 3: batch fermentation method

[0123] Various tested media for butanol production were: anaerobic sugar (AnS) medium (Isar et al., 2006); fortified Clostridium (RC) medium (Lin and Blaschek, 1983); soluble starch culture medium (SSM) (Moreira et al., 1981); alternative thioglycolic acid (AT) medium (Lin and Blaschek, 1983); potato starch medium (PSM) (Fouad et al., 1976). AnS was the best of the media tested, yielding 3.2 g / l of butanol (Table 1). Butanol production was optimized in AnS medium, where the influence of different physiological and nutritional parameters was investigated.

[0124] Table 1: Butanol production (g / l) in different media

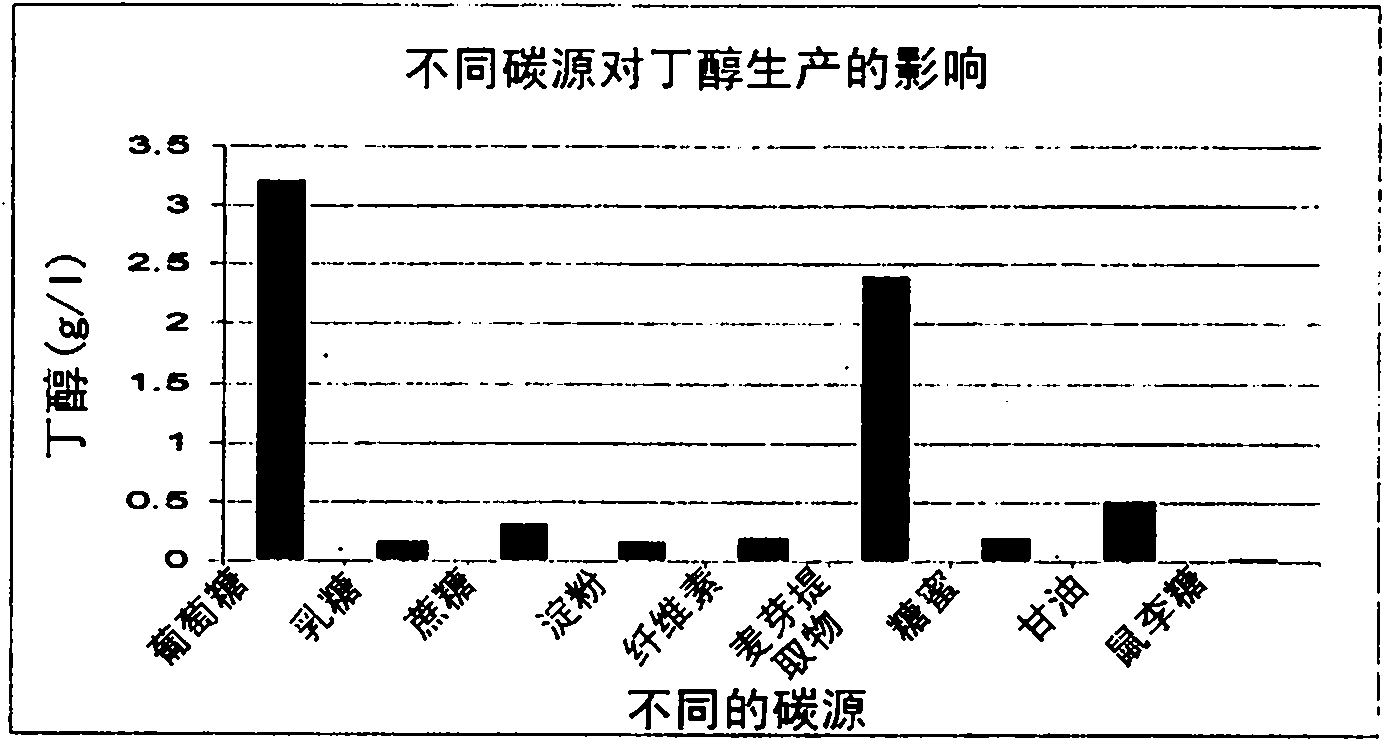

[0125]

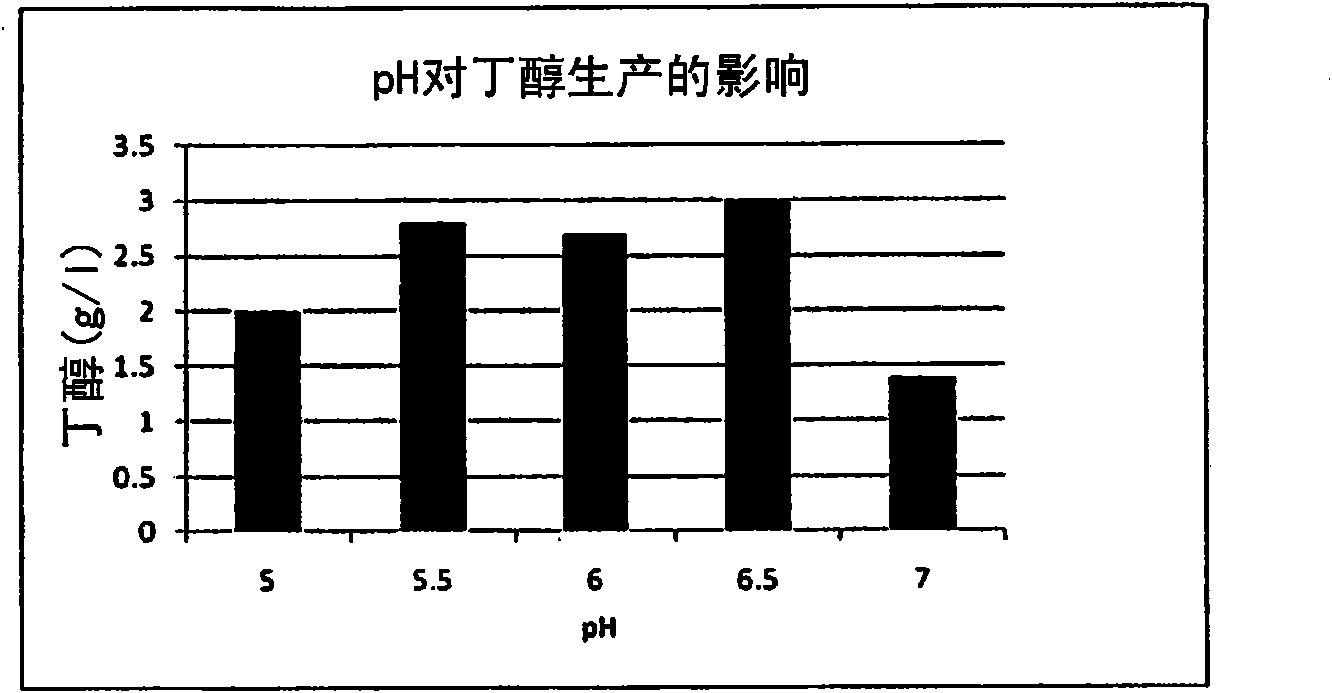

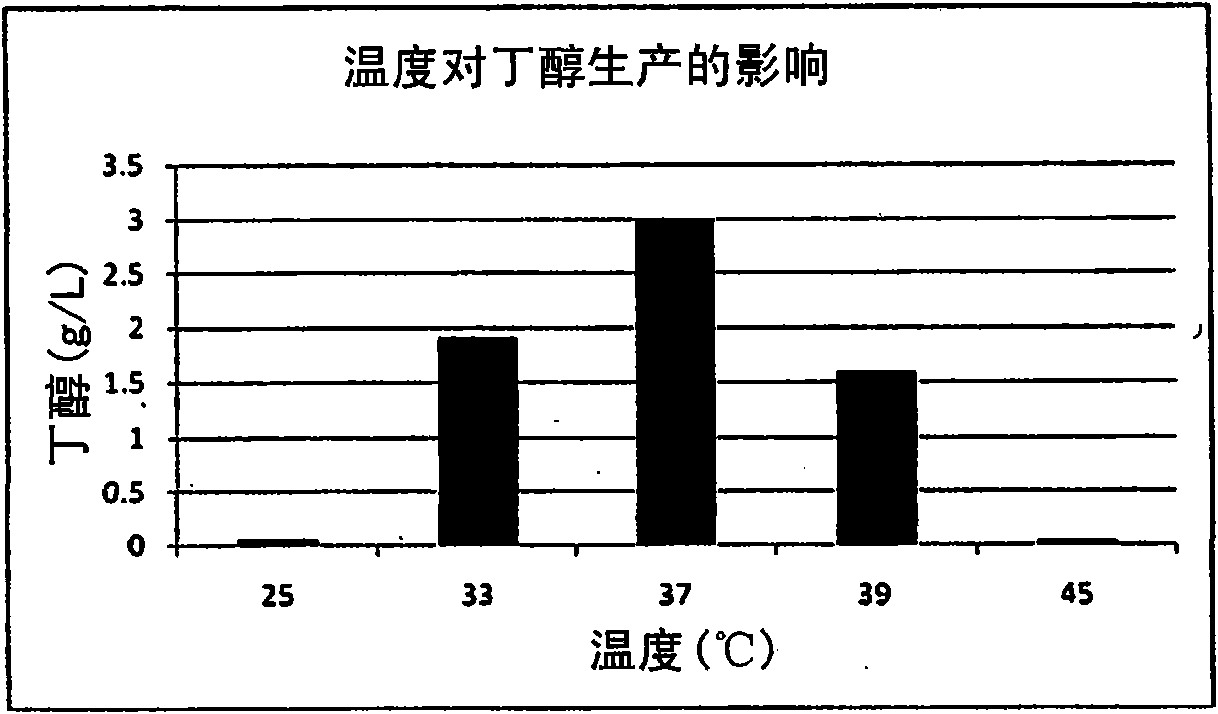

[0126] Subsequently, the effect of pH (5-7) and temperature (25-45°C) was studied in media selected for butanol production. The optimum pH for production was found to be 6.5 and 3.2 g / l of butanol was obtained within 84 hours (Figure 1). The results of the effect of different temperatures (25°C, 33°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com