Vertical vacuum frying machine

A technology of vacuum frying machine and frying machine, which is applied in the direction of oil/fat baking, etc., which can solve the problems of inconsistency, uneven frying effect, long frying time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

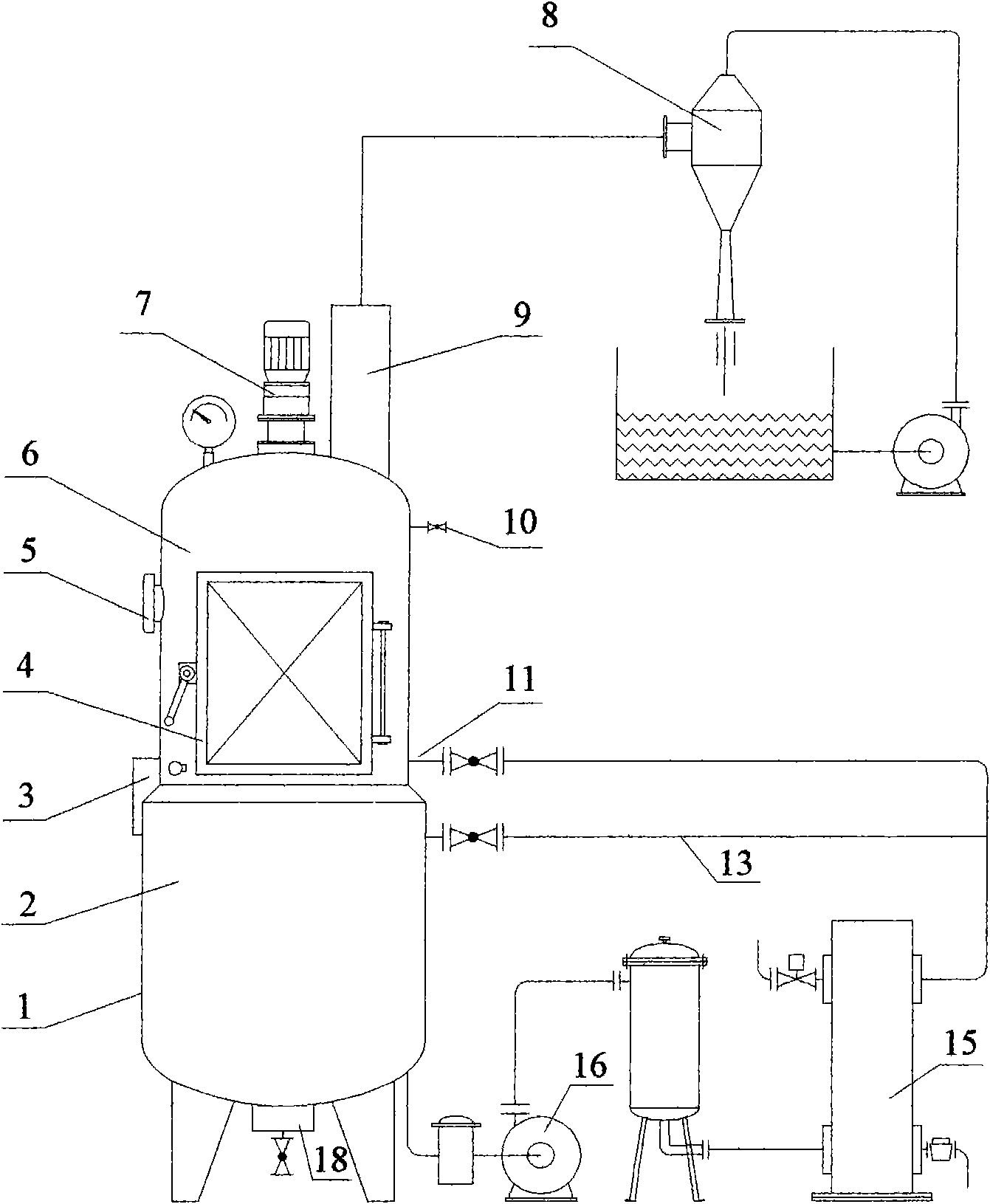

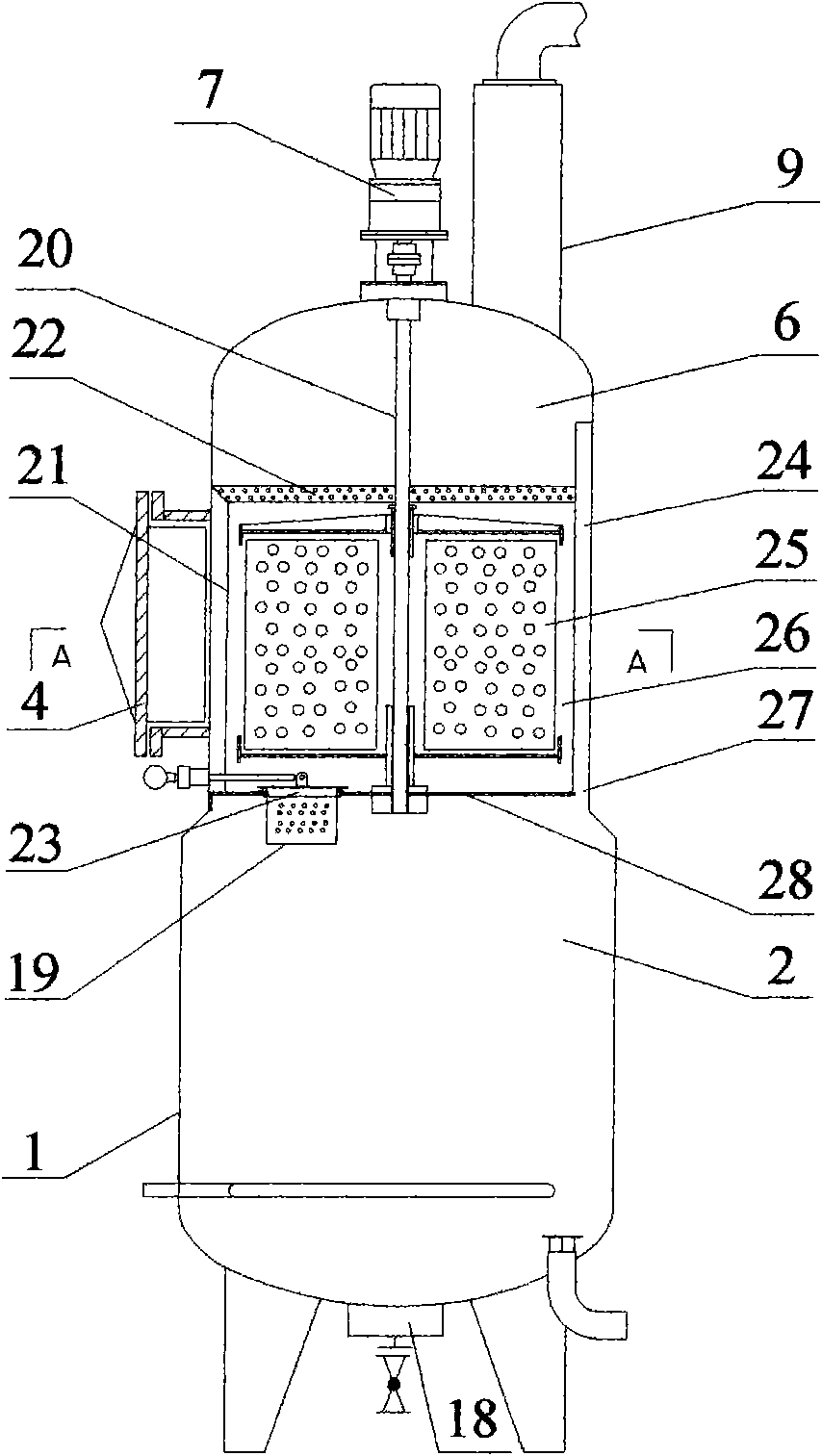

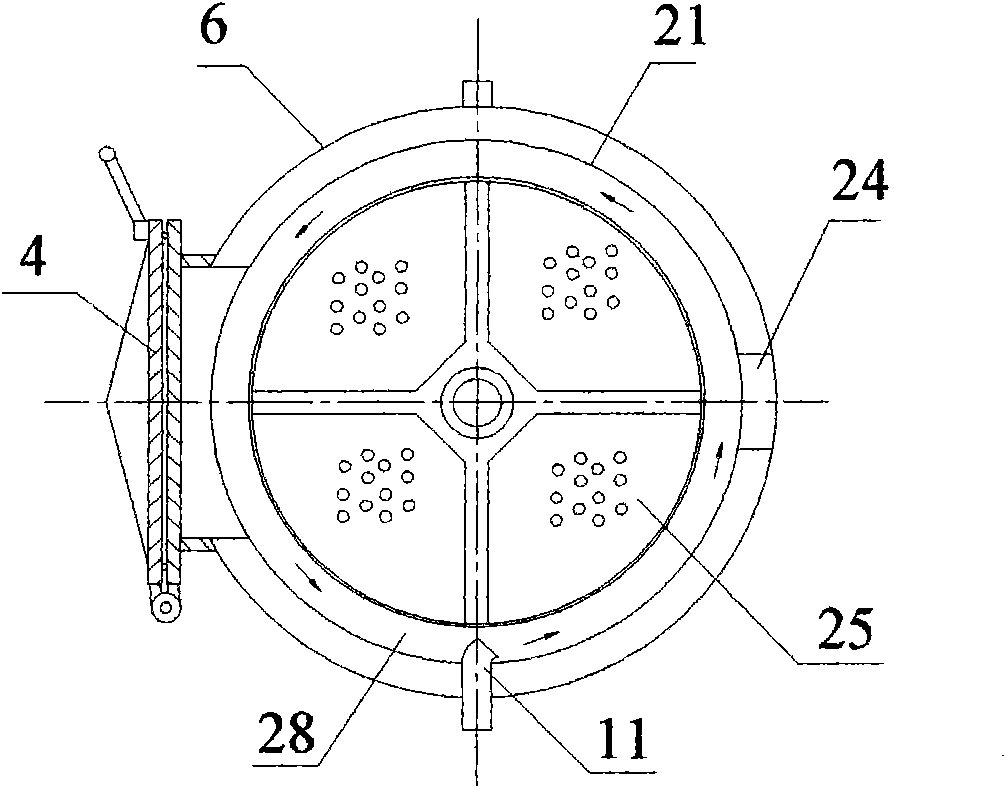

[0015] A vertical vacuum frying machine, the structure of the above frying machine includes a frying and deoiling bin 6 formed by separating the inner cavity of the tank body 1 by means of an intermediate partition 28, an oil storage bin 2, and an inside of the frying and deoiling bin 6 The frying basket 25 assembly positioned and set, and the working medium matched with the whole machine, as well as the oil external circulation continuous heating device and the vacuum servo mechanism, in the structure of the above-mentioned frying and deoiling chamber 6, in the corresponding frying basket 25 The part is surrounded by an interlayer structure on the wall of the frying and deoiling bin 6, and the interlayer structure is connected to the frying and deoiling bin 6 and the oil storage bin 2 to form an overflow channel 27.

[0016] The partition plate 21 forming the overflow channel 27 is positioned on the middle partition plate 28 and is fixedly connected to the inner wall of the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com