Horizontal rotary continuous processing equipment for milling, grinding and polishing

A technology of horizontal rotation and processing equipment, which is applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve problems such as batch processing, irregular surface shape, and low processing efficiency, and achieve consistent surface finish, consistent dimensional accuracy, and production The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

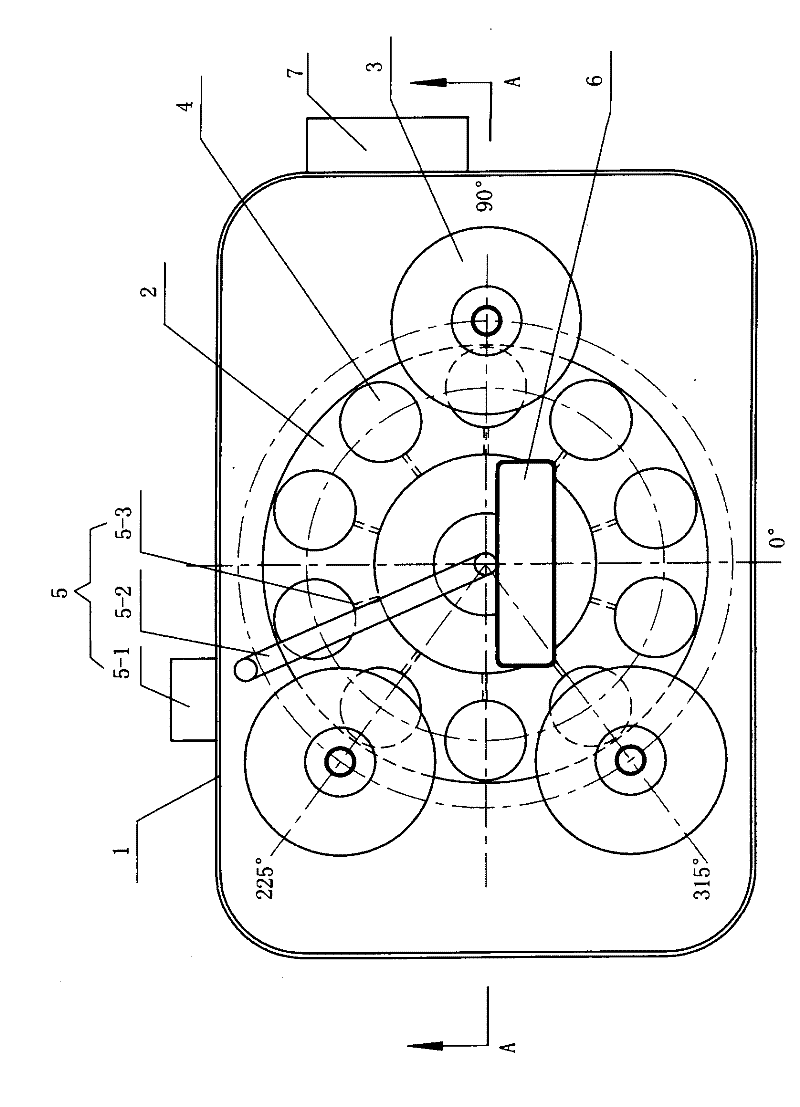

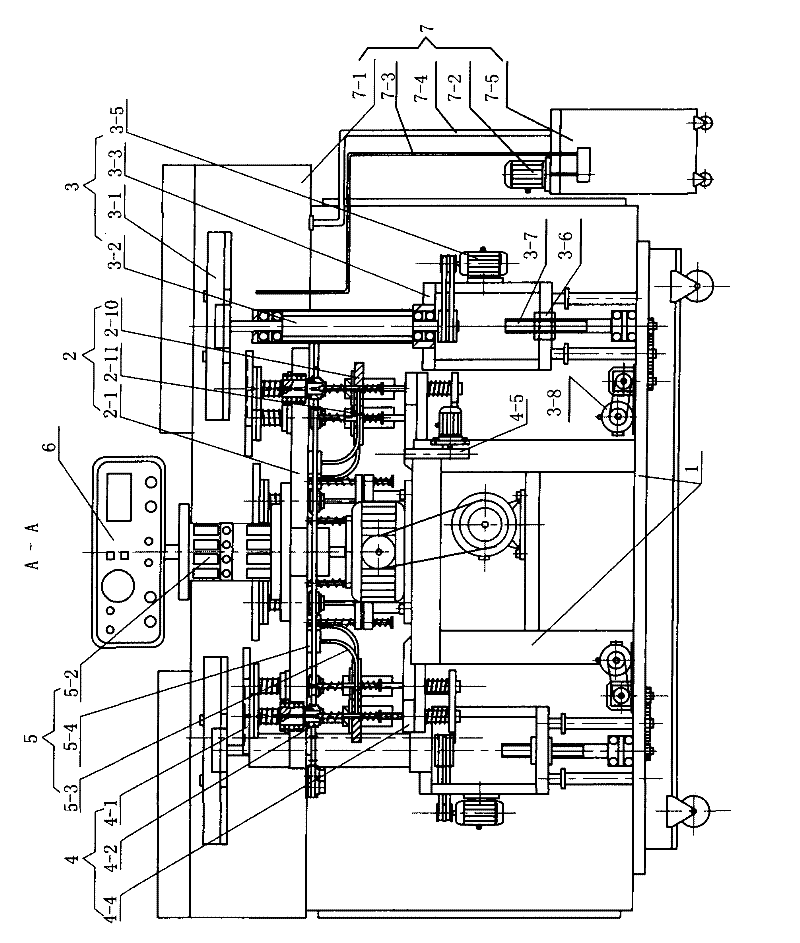

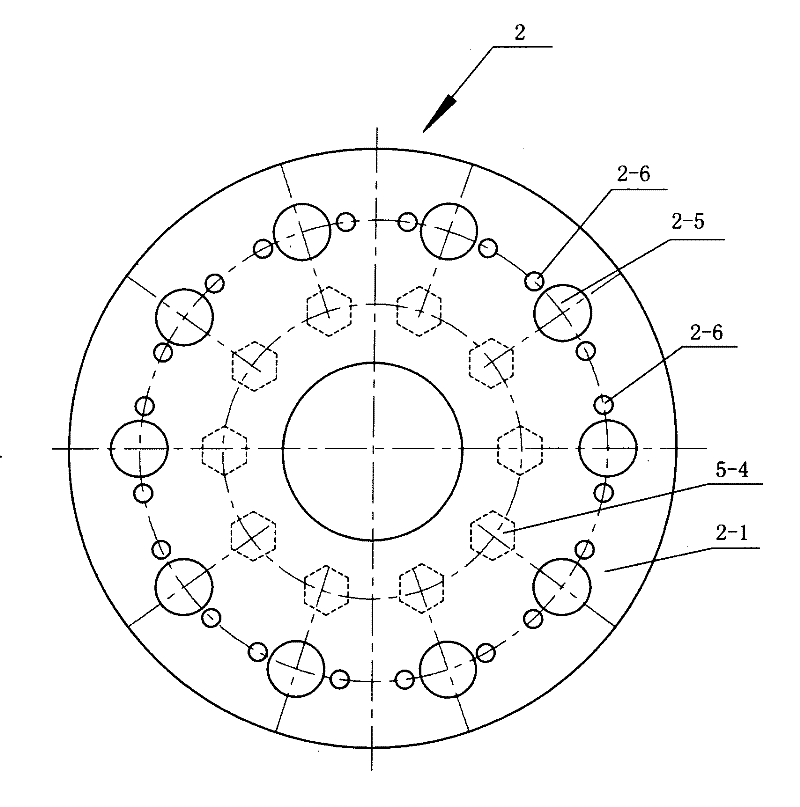

[0029] Such as figure 1 and figure 2As shown, a horizontal rotary continuous processing equipment for milling, grinding and polishing includes a frame 1, a rotary table transmission system 2 and three cutting disc transmission systems 3, and the rotary table transmission system 2 is set in the center of the frame 1 , the cutting disk transmission system 3 is evenly distributed on the outer periphery of the rotary table 2-1, and the three cutting disk transmission systems 3 are milling, grinding and polishing respectively; the equipment also includes a small workpiece disk transmission system 4, a small workpiece disk transmission system 4 includes 10 small workpiece disk combinations 4-1; the device also includes a vacuum pneumatic system 5, an electrical switch box 6 and a cutting fluid circulation system 7. The electrical control circuit is housed in the electrical switch box 6 . The vacuum pneumatic system 5 includes a total gas pipe 5-2, a gas distribution pipe 5-3 and ...

Embodiment 2

[0042] Such as Figure 12 As shown, it is a horizontal rotary continuous processing equipment for milling, grinding and polishing, including a frame 1, a rotary table transmission system 2 and 4 cutting disk transmission systems 3, and the 4 cutting disk transmission systems 3 are respectively for milling, roughing Grinding, fine grinding and polishing, the equipment also includes small workpiece disc transmission system 4, vacuum pneumatic system 5, electrical switch box 6 and cutting fluid circulation system 7, small workpiece disc transmission system 4 includes 10 small workpiece disc combinations In this device, the feed cam 4-5 is located under the milling cutter head 3-1, and the feed guide rail 4-4 is arranged under the cutter head 3-1 for rough grinding, fine grinding and polishing, and the rest of the structure is the same as that of the embodiment 1 is the same.

Embodiment 3

[0044] Such as Figure 13 As shown, it is a horizontal rotary continuous processing equipment for milling, grinding and polishing, including a frame 1, a rotary table transmission system 2 and 5 cutting disk transmission systems 3, and the 5 cutting disk transmission systems 3 are milling, roughing Grinding, fine grinding, rough polishing and fine polishing, the equipment also includes small workpiece disc transmission system 4, vacuum pneumatic system 5, electrical switch box 6 and cutting fluid circulation system 7, small workpiece disc transmission system 4 includes 12 A combination of small workpiece discs, in which the feed cam 4-5 is located under the milling cutter head 3-1, and the feed guide rail 4-4 is set on the cutter head 3-1 for rough grinding, fine grinding, rough polishing and fine polishing. 1 below, the rest of the structure is the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com