Superhigh temperature refractory pyrometric cone and preparation method thereof

A temperature measuring cone and ultra-high temperature technology, applied in thermometers, measuring devices, measuring heat and other directions, can solve the problems of difficult to accurately measure, cannot reflect the ambient temperature of the kiln well, and achieve intuitive and clear test results, filling the measurement gap. , the effect of rich source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

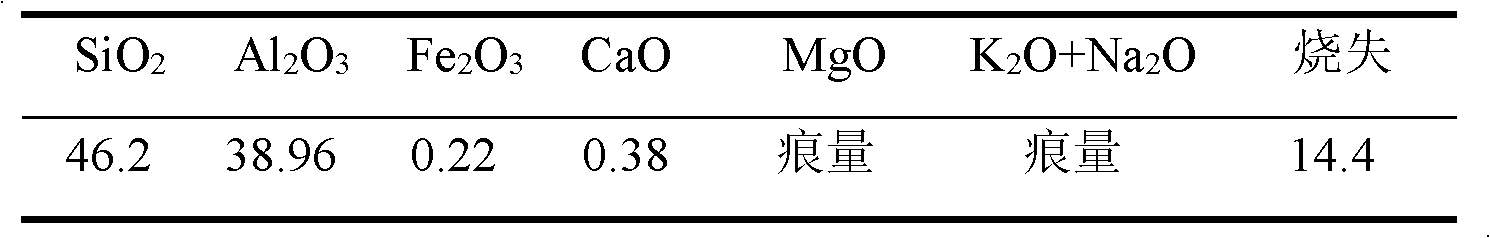

[0026] Preparation of 1820℃ temperature measuring cone

[0027] Mix clay, quartz sand and alumina according to the mass ratio of 80:3:17, use 1% water glass solution as an additive, and use a triangular pyramid mold to form it by hand; The high-temperature furnace is pre-fired at 1000-1200°C for 6-10 hours and then cooled to obtain the product.

[0028] The composition of the temperature measuring cone is 47-50wt.%Al 2 o 3 , 49~52wt.% SiO 2 , Fe 2 o 3 0.01~1wt.%, K 2 O+Na 2 O is 0-1wt.%, and CaO is 0.01-0.5wt.%. After measuring and comparing with the 1800°C national standard temperature measuring cone and the 1820°C German standard temperature measuring cone, its refractoriness is 1820°C.

Embodiment 2

[0030] Preparation of 1820℃ temperature measuring cone

[0031] Mix clay, quartz sand and alumina according to a mass ratio of 93:2:5, use 2% water glass solution as an additive, and use a triangular pyramid mold for hand molding; after molding, dry in an oven at 60°C for 30 to 60 hours, and then enter The high-temperature furnace is pre-fired at 1000-1200°C for 6-10 hours and then cooled to obtain the product.

[0032] The composition of the temperature measuring cone is 47-50wt.%Al 2 o 3 , 49~52wt.% SiO 2 , Fe 2 o 3 0.01~1wt.%, K 2 O+Na 2 O is 0-1wt.%, and CaO is 0.01-0.5wt.%. After measuring and comparing with the 1800°C national standard temperature measuring cone and the 1820°C German standard temperature measuring cone, its refractoriness is 1820°C.

Embodiment 3

[0034] Preparation of 1880℃ temperature measuring cone

[0035] Mix clay, quartz sand and alumina according to the mass ratio of 50:2.5:47.5, use 3% water glass solution as an additive, and use a triangular pyramid mold to form it by hand; The high-temperature furnace is pre-fired at 1000-1200°C for 6-10 hours and then cooled to obtain the product.

[0036] The composition of the temperature measuring cone is 66 ~ 69wt.% Al 2 o 3 , 30~33wt.% SiO 2 , Fe 2 o 3 0.01~0.6wt.%, K 2 O+Na 2 O is 0-0.8wt.%, and CaO is 0.01-0.3wt.%. After comparing with the 1880°C German standard temperature measuring cone, its refractoriness is 1880°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Refractoriness | aaaaa | aaaaa |

| Refractoriness | aaaaa | aaaaa |

| Refractoriness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com