Mechanical loading flow chamber device for co-culturing in-vitro cells

A cell culture, flow chamber technology, applied in the field of biomechanical engineering research, can solve problems such as inappropriate multi-view cell biomechanics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

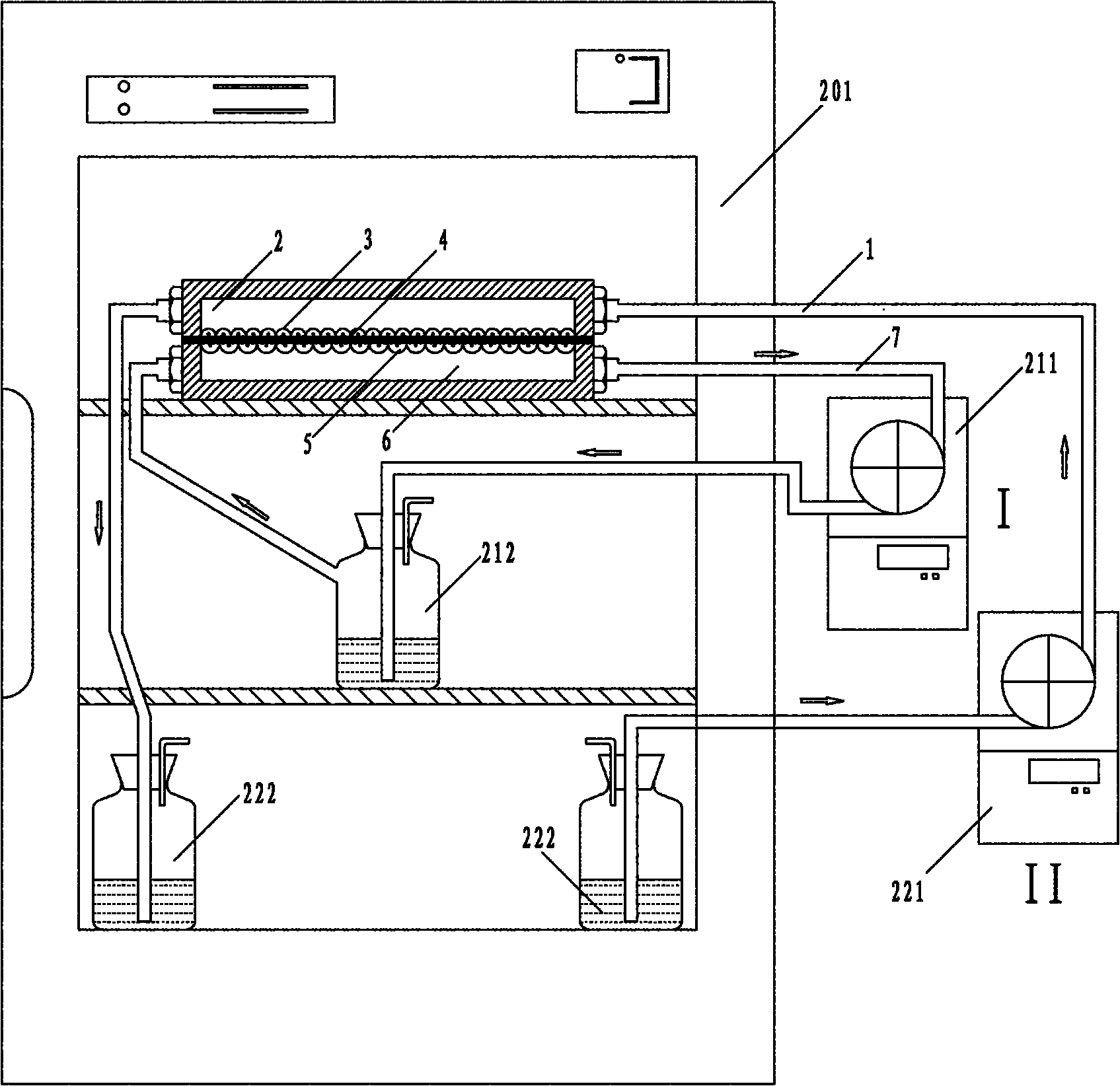

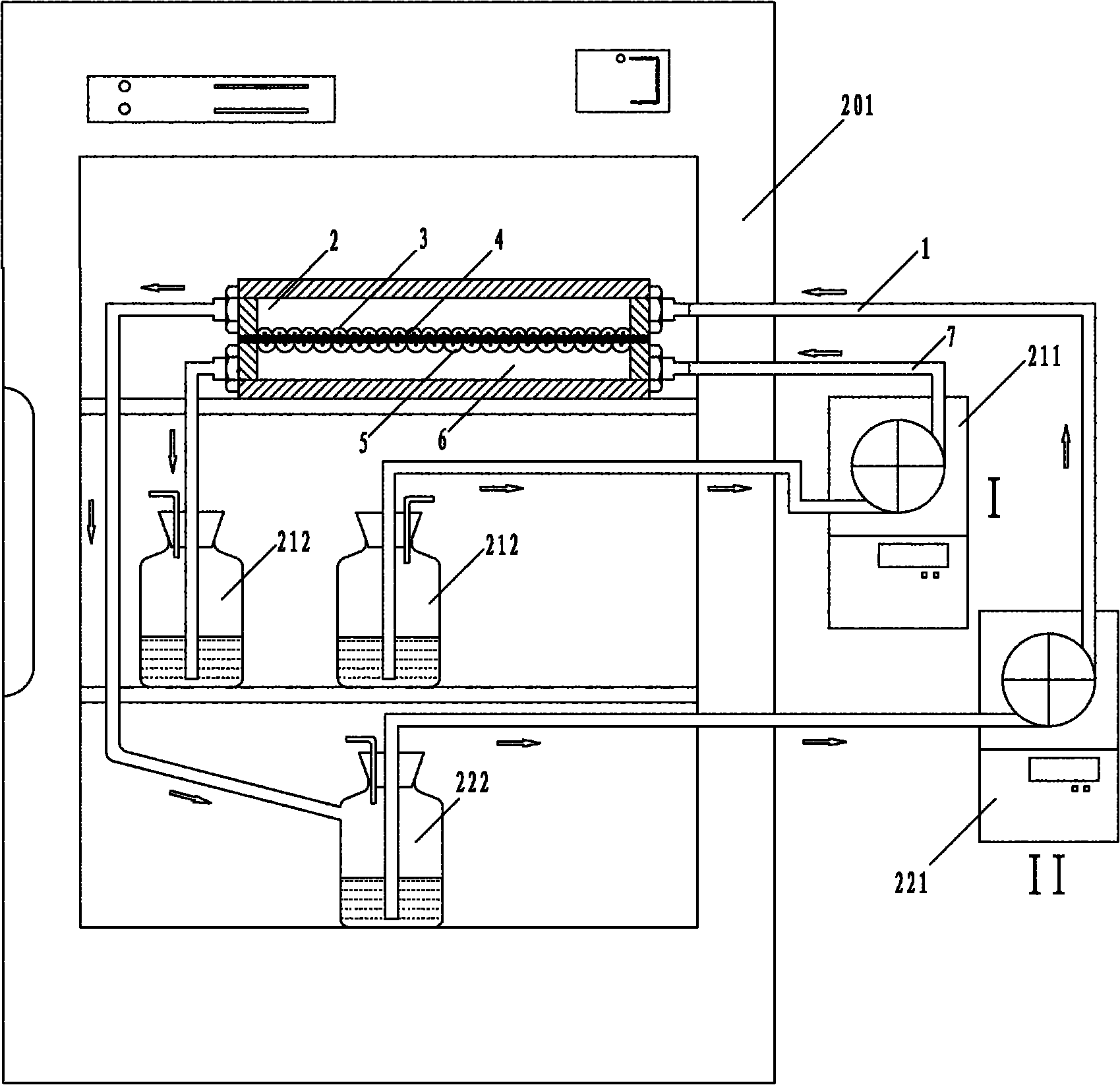

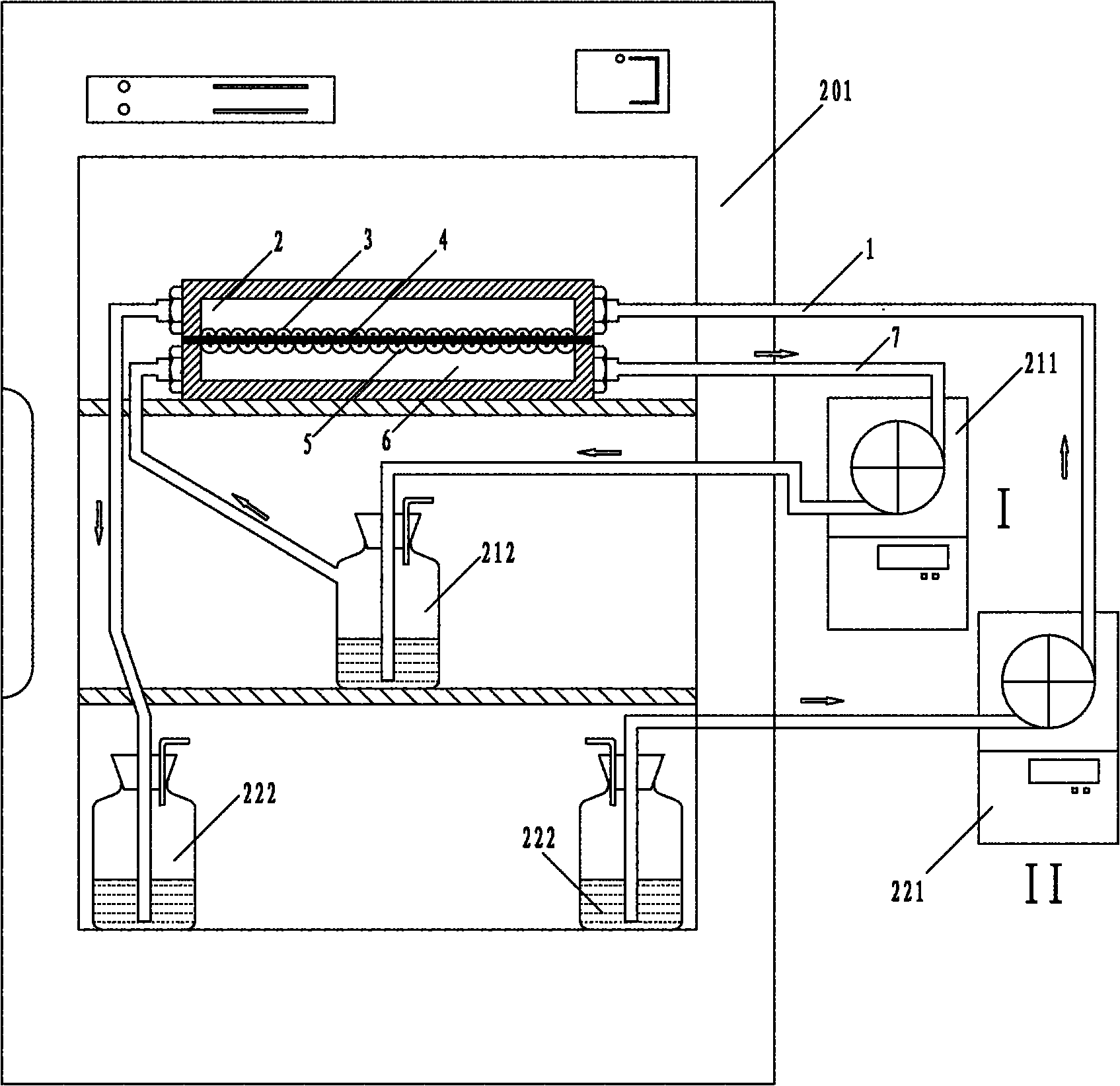

[0026] The present invention will be described below in conjunction with the accompanying drawings and embodiments.

[0027] In the parallel plate flow chamber, the relationship between shear force, circulating fluid flow rate, circulating fluid viscosity and flow chamber size is: τ=6μQF / WH 2 .

[0028] F depends on the aspect ratio (W / H) of the flow chamber, and when W / H>>1, F≈1. Where τ is the shear stress at the bottom of the flow chamber (dyn / cm 2 ); μ is the perfusate viscosity (dyn s / cm 2 ); Q is the flow rate (cm 3 / s); W is the width of the flow chamber (cm); H is the height of the flow chamber (cm). In the system according to one embodiment of the present invention, the culture medium contains 10% FBS, and the perfusate viscosity μ is the dynamic viscosity, with a value of 0.013 dyn s / cm 2 . In the experiment, the dimensions of the two flow chambers are both W=3cm and H=0.05cm. When shear stress τ=15dyn / cm 2 , Q=τWH 2 / 6μF≈1.4423cm 3 / s.

[0029] The Reynol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com