High-temperature furnace sealing device for continuously producing carbon fibres

A sealing device and high-temperature furnace technology, applied in the chemical characteristics of fibers, textiles and papermaking, etc., can solve the problems of inconvenient cleaning and maintenance, poor sealing effect, complex structure, etc., to facilitate daily cleaning, reduce mechanical damage, and seal good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

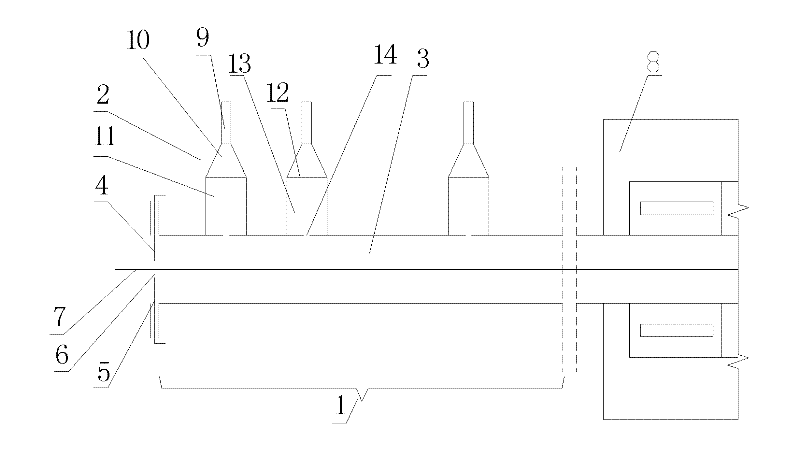

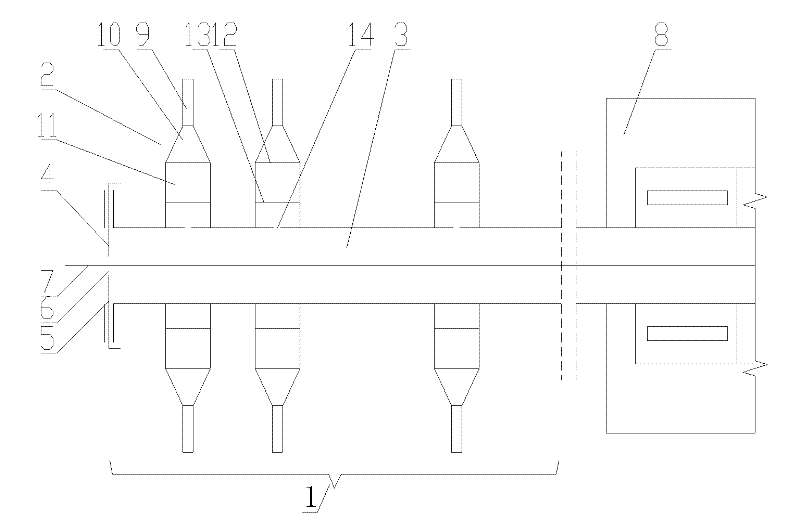

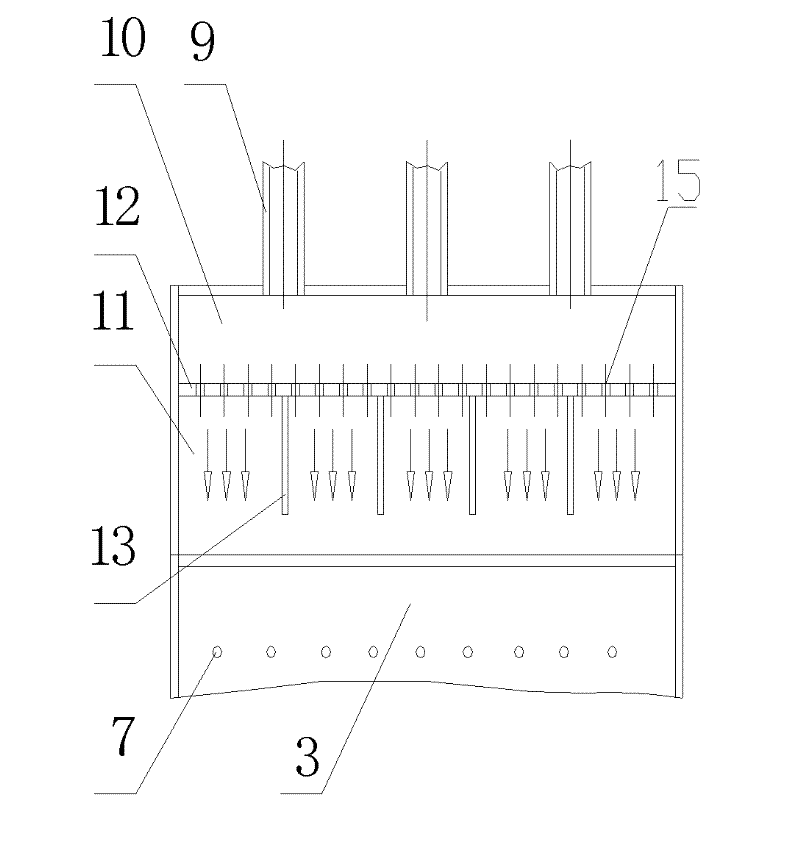

[0026] The present invention is used for the high-temperature furnace sealing device of continuous production carbon fiber such as figure 1 As shown, it can be applied to the entrance and exit of the pre-oxidized fiber tow 7 of the high temperature furnace 8, mainly composed of a sealed chamber 3 and a number of air intake components 2, and one end of the sealed chamber 3 is a gap for the fiber tow to enter and exit 6. The gate-type structure of the upper gate 4 and the lower gate 5 is used to adjust the width of the gap, and the other end communicates with the furnace mouth of the high-temperature furnace 8, and is usually connected by fasteners; several air intake components 2 are arranged in the sealed chamber 3 One side, upper and lower sides or surroundings of the main body are mainly composed of intake pipe 9, expansion chamber 10, rectification chamber 11, and air inlet 14; the number of intake components 2 is determined by the size of the furnace mouth of the high-tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com