Tencel fiber spinning process

The invention relates to a technology of tencel fiber and process, which is applied in the spinning process of tencel fiber. It can solve problems such as poor cohesion, poor resilience, and low moisture regain of Tencel fibers.

Inactive Publication Date: 2011-01-26

SHANGHAI SHENAN TEXTILE

View PDF1 Cites 27 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to overcome the deficiencies of the prior art and provide a Tencel fiber spinning process that can solve the problems of low moisture regain, poor resilience, and poor cohesion of the Tencel fiber.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

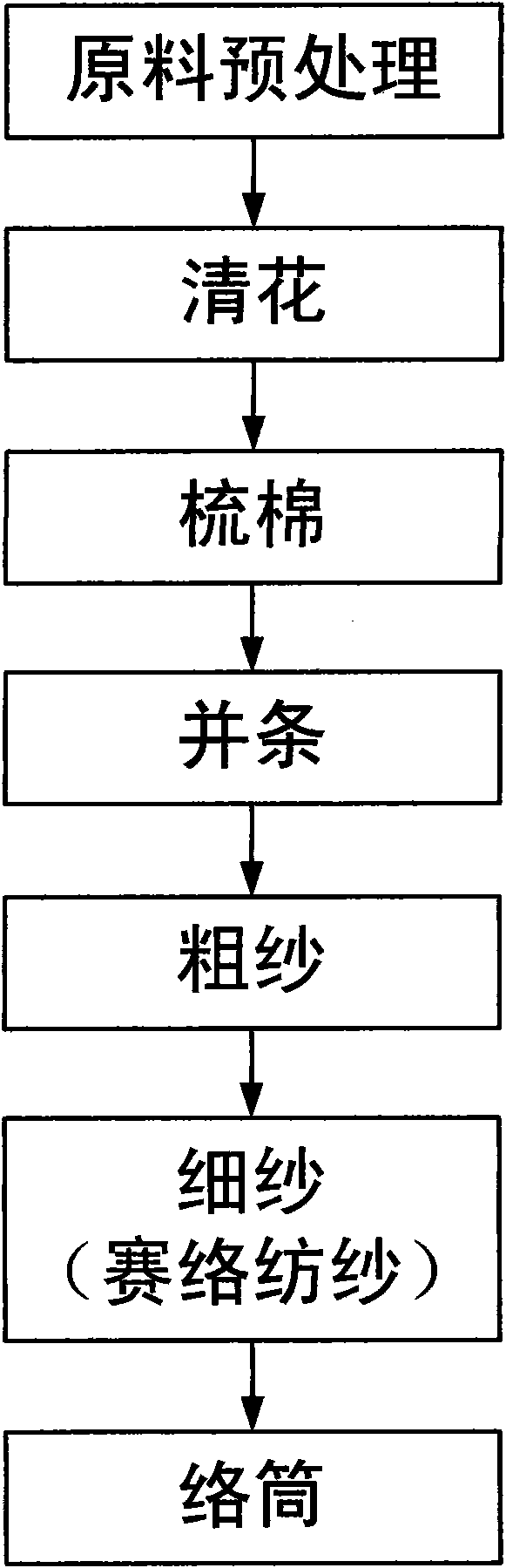

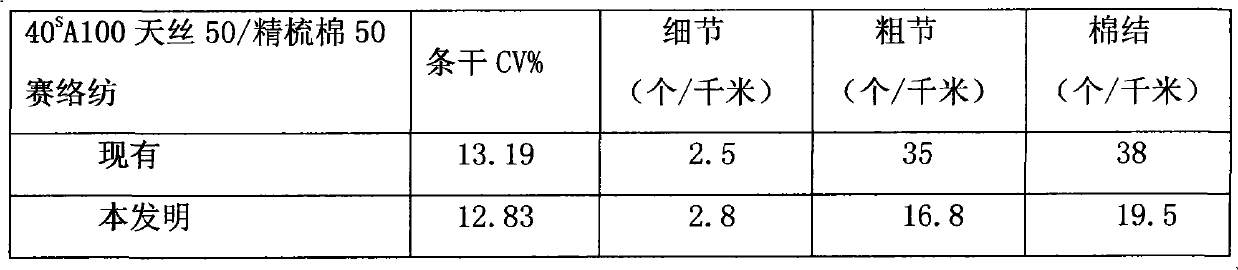

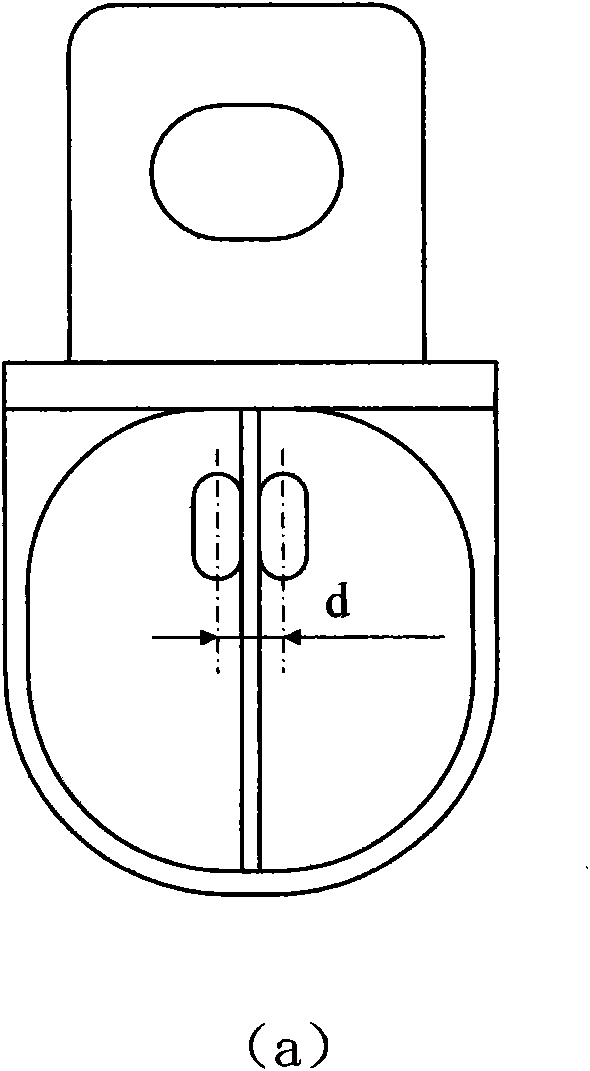

The invention relates to the technical field of tencel fiber spinning, in particular to a tencel fiber spinning process. The tencel fiber spinning process is characterized in that the tencel fiber is prepared by adopting the following steps of: (1) preprocessing raw materials; (2) blowing; (3) carding cotton; (4) drawing; (5) roving; (6) spinning by using siro spinning technology; and (7) spooling. In the invention, the raw materials are preprocessed, and the siro spinning technology is adopted, so that knitting products prepared by the tencel fiber have optimal smoothness, drapability and elegance, are comfortable and soft and have high air permeability, rebound resilience and cohesive force.

Description

[technical field] The invention relates to the technical field of fiber spinning, in particular to a tencel fiber spinning process. [Background technique] Tencel A100 is an upgraded product based on the standard Tencel product "Tencel G100" of Austrian Lenzing Company. Tencel G100, also known as fibrillated Tencel, will produce the ideal effect of "peach skin" after dyeing and finishing, but it also limits its expansion in the field of clothing applications. Tencel A100, also known as non-fibrillated Tencel, eliminates the characteristics of fibrillation while retaining many excellent properties of G100. The surface is smoother and the application field is expanded. It is especially suitable for the development of knitted products. Tencel A100 fiber has a smooth surface, soft luster, good moisture absorption and air permeability, high strength and low elongation, high wet modulus, and dry and wet strength close to each other. It combines the comfort of pure cotton, high te...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): D02G3/02D02G3/22

Inventor 卢国明王乐君王苏平

Owner SHANGHAI SHENAN TEXTILE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com