LED driving loop

A technology of LED driving and driving circuit, applied in the direction of electric lamp circuit layout, lighting device, light source, etc., can solve the problem of brightness drop, it is difficult to adjust the brightness of lighting fixtures in a large scale, etc., so as to reduce the brightness difference and reduce the impact. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The preferred embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

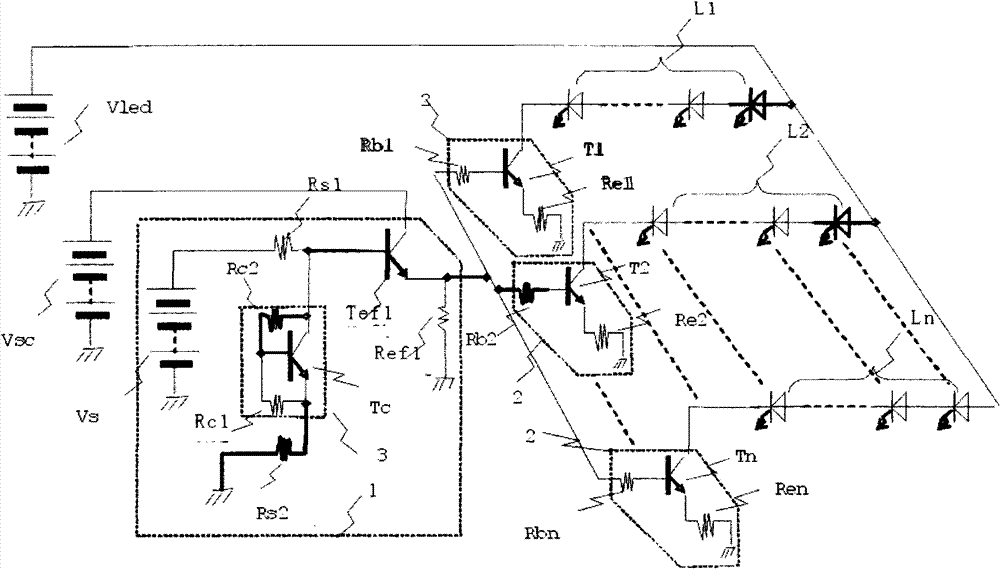

[0017] Accompanying drawing is the schematic diagram of LED drive circuit in the preferred embodiment of the present invention, and the function of this LED drive circuit is divided into one or several serial LED columns Ln (n: 1~n) (one end connects power supply Vled, the other end connects drive The drive unit 2) of each LED column Ln and the control unit 1 that controls the LED drive unit 2 and controls the current value.

[0018] The driving part 2 is made up of n transistors Tn (n: 1~n), and the collector of the transistor {is used to drive k (k is a natural number more than 1) in series, n columns (n is a natural number more than 1) ) composed of k×n LEDs} are connected to the LED column Ln (n: 1~n), the emitter is connected to Ren (n: 1~n), and the base is connected to Rbn (n: 1~n).

[0019] The value of resistor Ren is set in con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com