Continuous casting system particularly for long steel products, and a method for continuous casting

A technology for steel products and continuous casting, which is applied to continuous casting equipment and continuous casting fields especially for long steel products, which can solve the problems of time-consuming re-generation of standby state, difficulty in taking out broken billets, etc., and shorten the time for reinstallation and adjustment , Guarantee symmetrical cooling, and reduce the risk of damage to the surface of the slab

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

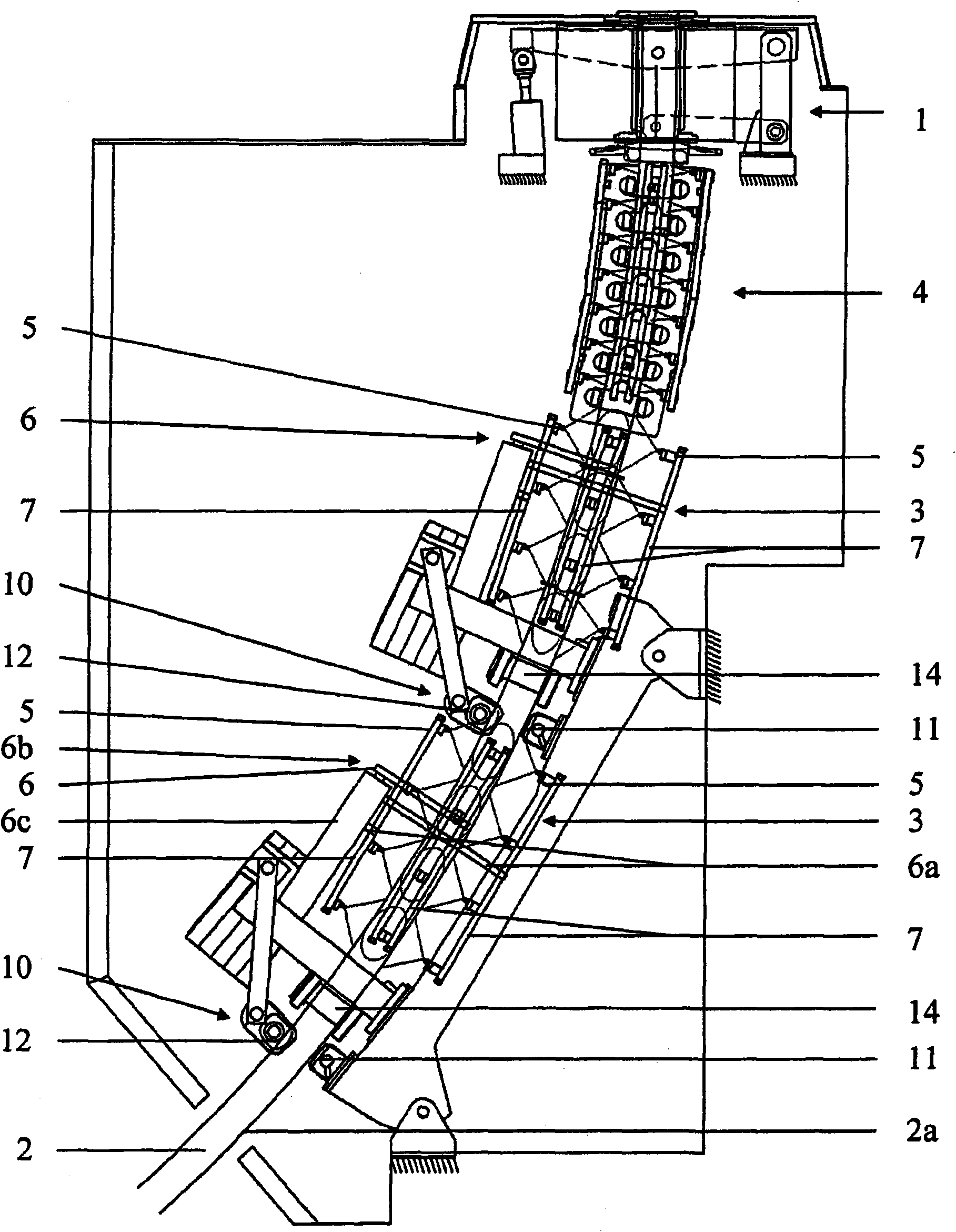

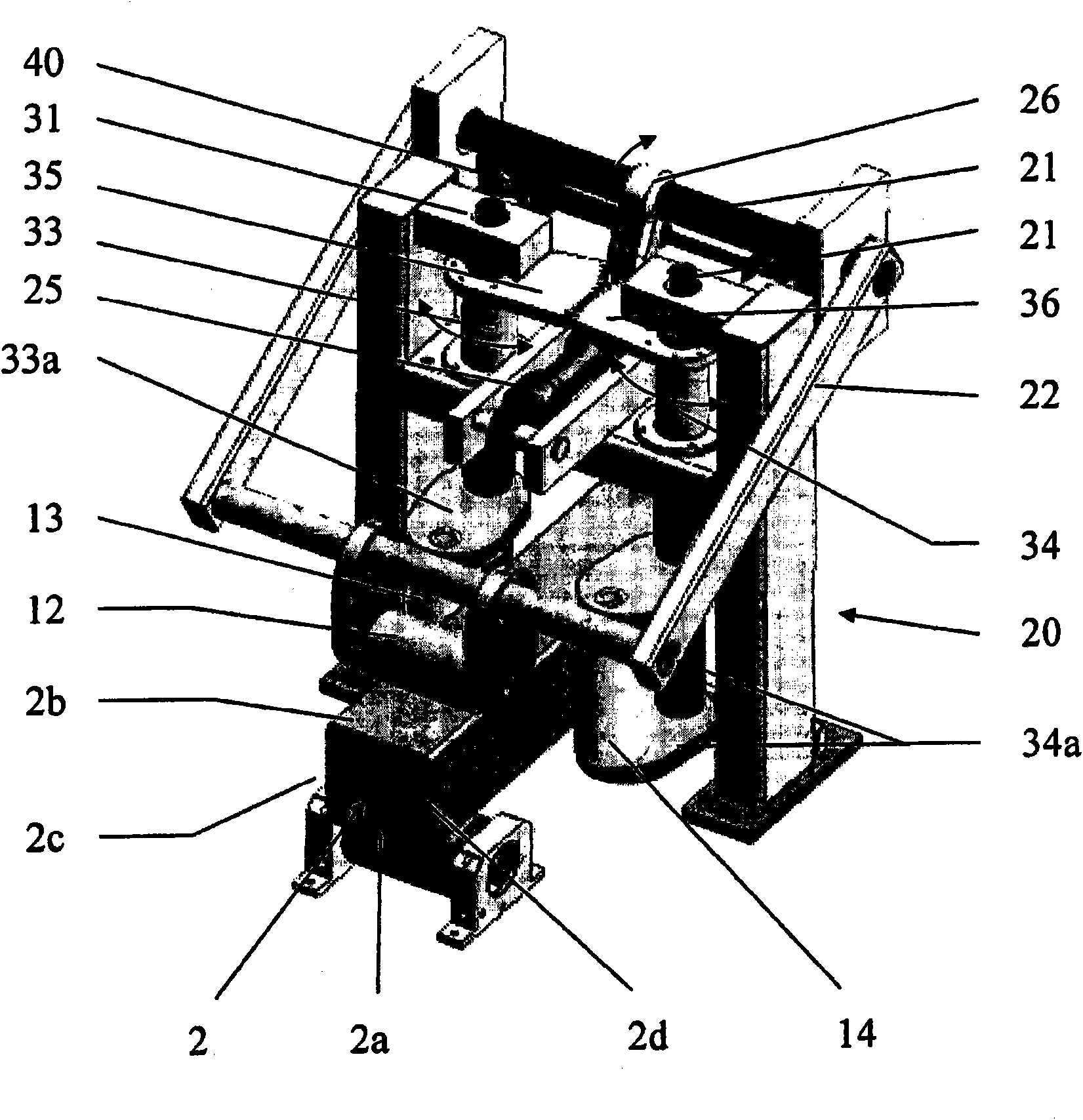

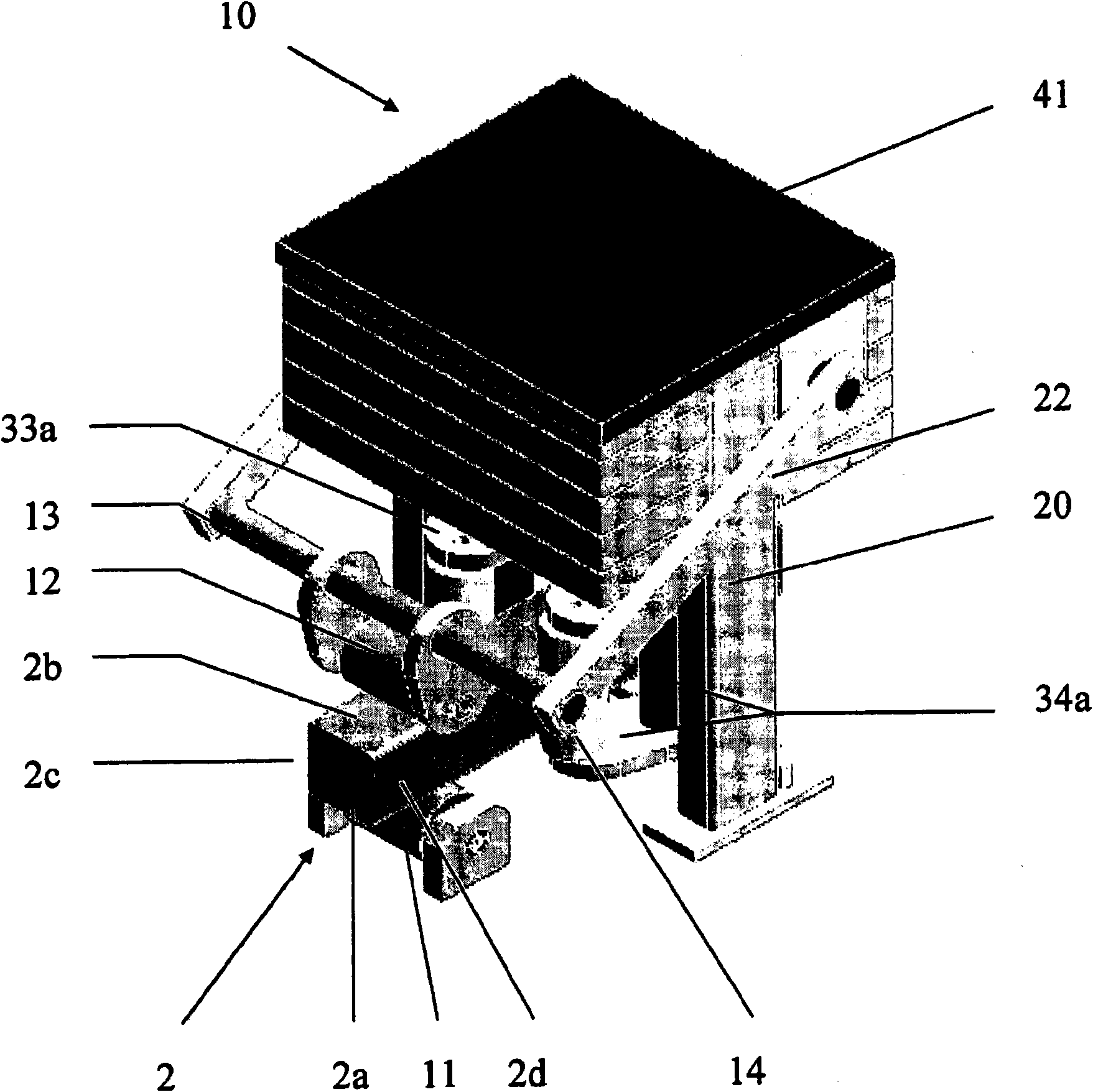

[0018] according to figure 1 The continuous casting equipment includes a mold 1 in which liquid metal, especially molten steel, is continuously drawn out from below the water-cooled mold 1 in the form of a billet 2 in the form of a billet shell. The cast strand is guided through other cooling devices, so-called secondary cooling devices, while being further cooled. According to requirements, multiple support rollers and spraying mechanisms 4 can be installed at the outlet of the crystallizer as so-called bottom roller supports and support sections. They depend on the specification and are replaced with the mold when the casting specification changes.

[0019] The cooling device includes a plurality of spray modules 3 arranged one behind the other. In the spray modules, the casting slab 2 guided along the guide roller table is applied with a cooling medium, generally water or a water-air mixture. To this end, each cooling module 3 is equipped with a plurality of nozzles 5 in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com