Manufacturing method of multilayer nonwoven material and manufacturing equipment thereof

A technology of non-woven materials and manufacturing methods, applied in the field of non-woven materials and multi-layer non-woven materials, can solve the problems of high production cost, many machines, large floor space, etc., so as to reduce the production cost and reduce the production process. changing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The general process flow of multi-color non-woven materials is: rough opening → fine opening → blending → carding → laying → consolidation.

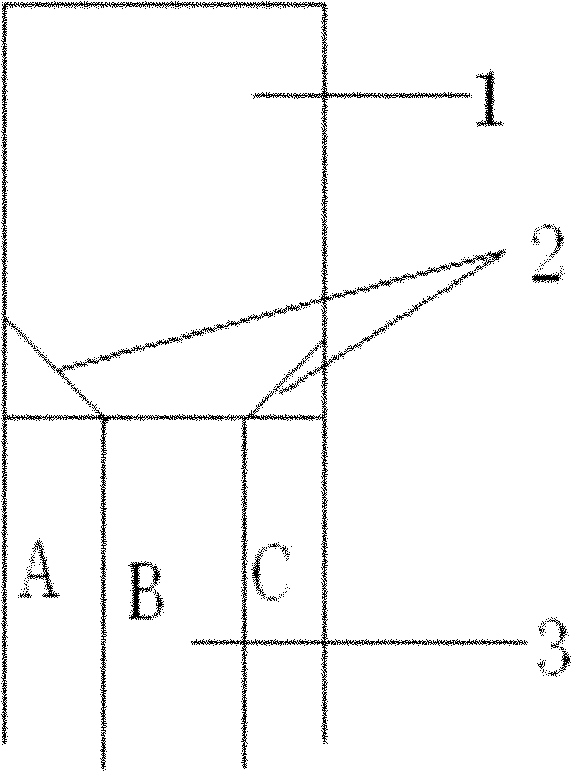

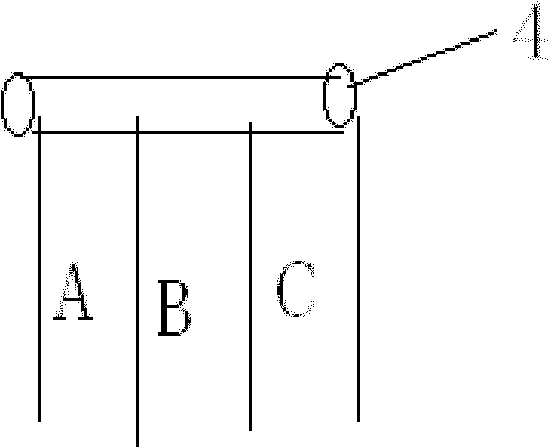

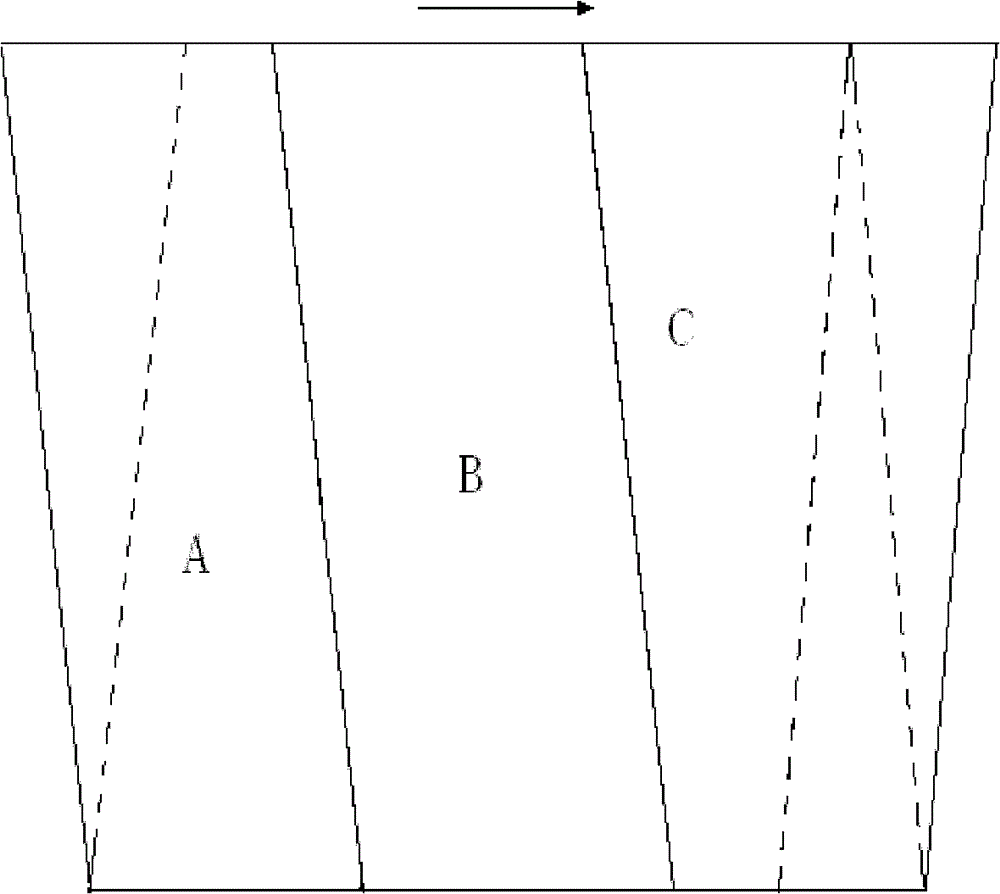

[0023] Such as figure 1 As shown, in the cotton mixing process, two mixing baffles 2 are set in the mixing box 1, and the mixing box is divided into three independent parts, and each independent part is provided with a raw material inlet, and one of the raw material inlets is connected with the cotton mixing The feed openings of the boxes are connected, and two feeding baffles are arranged on the feeding curtain for partitioning, and the feeding baffles are connected with the baffles 2 of the mixing box. When the colored fiber B is mixed, it only falls into the middle part of the mixing box. After the colored fibers A and C are roughly opened and finely opened, they are manually put into the other two raw material inlets of the mixing box. The angle of the two baffles 2 in the center can be used to adjust the area occupied by A, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com